Contents

Source: MDPI

Understanding Laser Surface Modification Techniques

Laser surface modification is a pivotal technique in the field of material processing, aiming to enhance the physical and chemical properties of various materials. This post delves into the diverse methodologies and applications of laser surface modification, highlighting its advantages over traditional processes.

What is Laser Surface Modification?

Laser surface modification refers to a range of processes that alter the surface characteristics of materials such as metals, ceramics, glasses, and polymers. These processes typically involve laser beams interacting with the material surface, sometimes with additional substances applied. The goal is to improve mechanical, chemical, or physical properties without affecting the bulk of the material.

Advantages of Laser Surface Modification

Laser surface modification offers significant benefits over conventional methods:

- Precision: Lasers can target specific areas on a surface, allowing for precise modifications without affecting surrounding material.

- Speed: The process is rapid, making it economically viable for industrial applications.

- Non-contact Process: As no physical contact is needed, there is minimal risk of contamination or tool wear.

- Accessibility: Lasers can modify surfaces in hard-to-reach areas, such as inside small-diameter holes.

- Automation Potential: The process can be automated and integrated with other manufacturing steps.

Examples of Laser Surface Modification Techniques

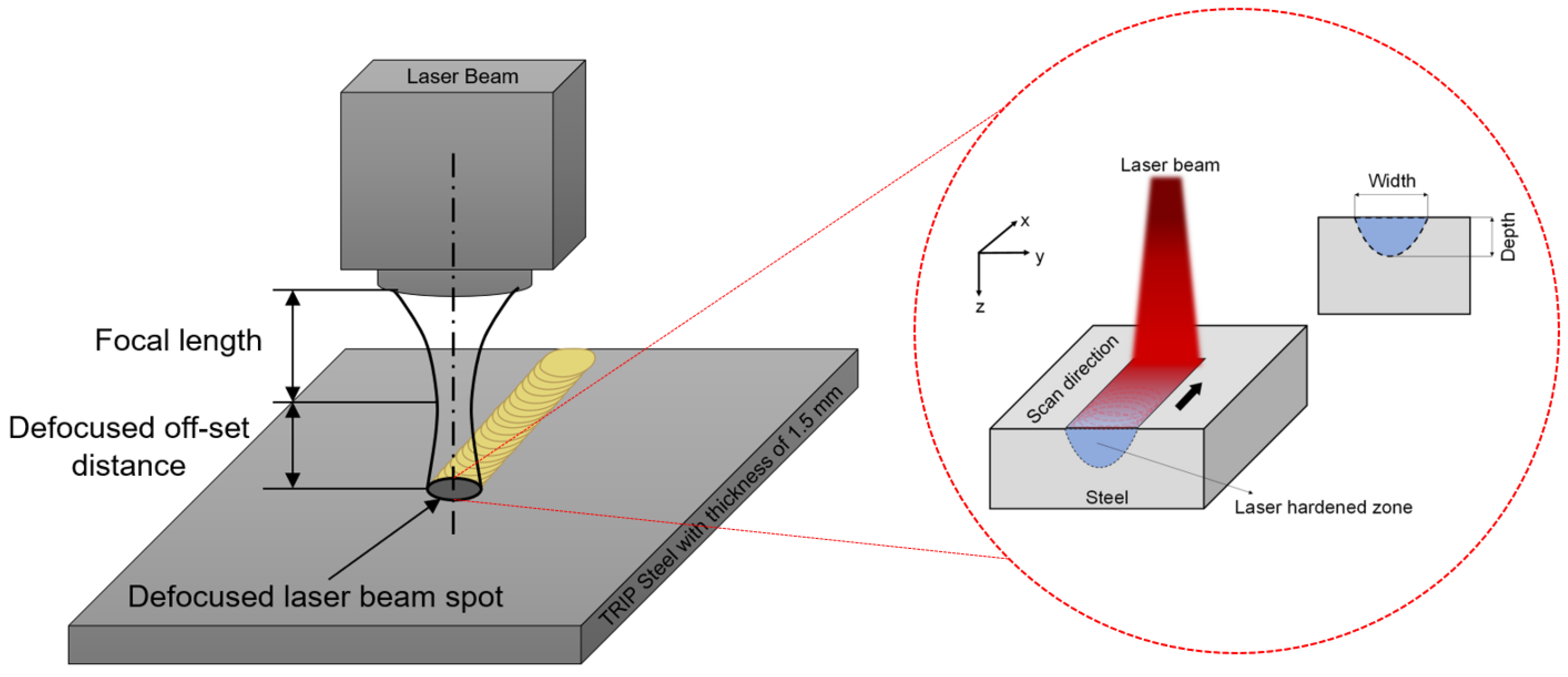

Laser Hardening

Laser hardening is a crucial industrial application, particularly for carbon-rich steels and cast iron. By heating the surface to approximately 1000°C and allowing it to cool rapidly, the steel structure transforms from austenite to martensite, resulting in increased hardness. This technique is widely used in manufacturing durable machine parts like turbine blades and gear wheels.

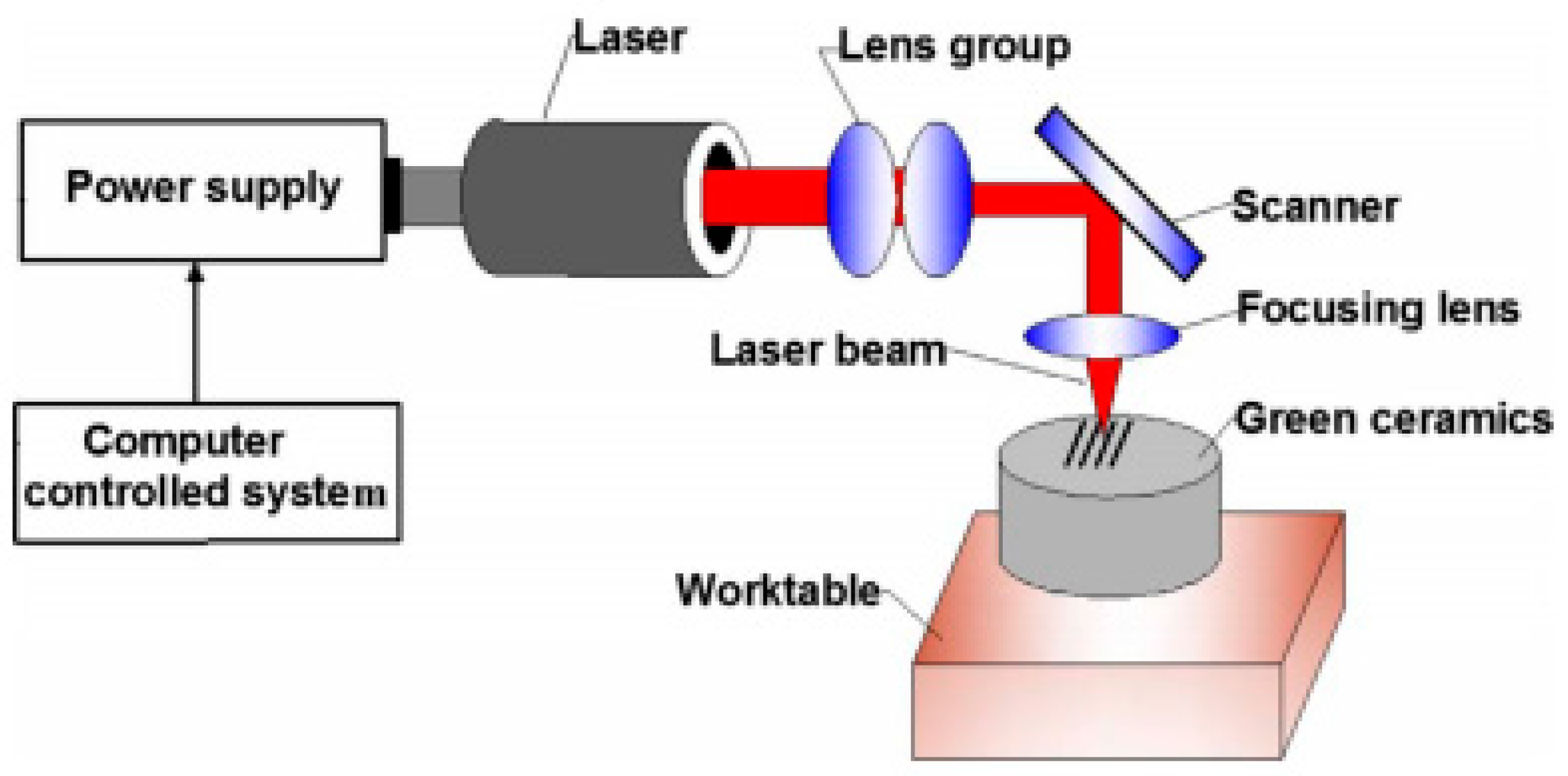

Laser Remelting and Vitrification

Laser remelting involves melting the material surface, which then re-solidifies with altered properties. This can lead to the removal of non-metallic substances or changes in crystal structures. Vitrification, a form of remelting, results in a glass-like surface layer and is applicable to special metal alloys and ceramics.

Laser Honing

Laser honing enhances the durability and reduces friction of engine components like pistons and cylinders. Intense ultraviolet laser pulses create a robust, nanostructured surface layer, often in a nitrogen atmosphere, incorporating nitrogen into the material.

Laser Alloying

Laser alloying involves creating surface alloys by incorporating additional chemical species. These can be introduced as powders or gases, reacting with the molten surface to form compounds like carbides or nitrides, which enhance abrasion and corrosion resistance.

Laser Texturing and Patterning

Laser texturing creates micro-patterns on surfaces, affecting properties like friction, wettability, and thermal conductivity. Controlled irradiation can produce regular patterns, aiding in subsequent processes such as coating applications.

Thermo-chemical Processes

These processes involve high-temperature chemical reactions initiated by laser heating. For instance, processing silicon carbide surfaces in a chlorine atmosphere can improve abrasion resistance by forming graphite grains.

Laser Coating

Laser coating is a method of applying surface coatings that significantly alter properties such as hardness and chemical resistance. This technique is integral to enhancing the performance and longevity of materials.

Conclusion

Laser surface modification is a versatile and efficient technique that offers numerous benefits over traditional methods. Its ability to precisely target and modify material surfaces makes it invaluable in various industrial applications, leading to improved product performance and durability.

Source: MDPI

Feel free to comment your thoughts.