Source: Coherent

Understanding Laser Marking: Applications and Technology

Introduction to Laser Marking

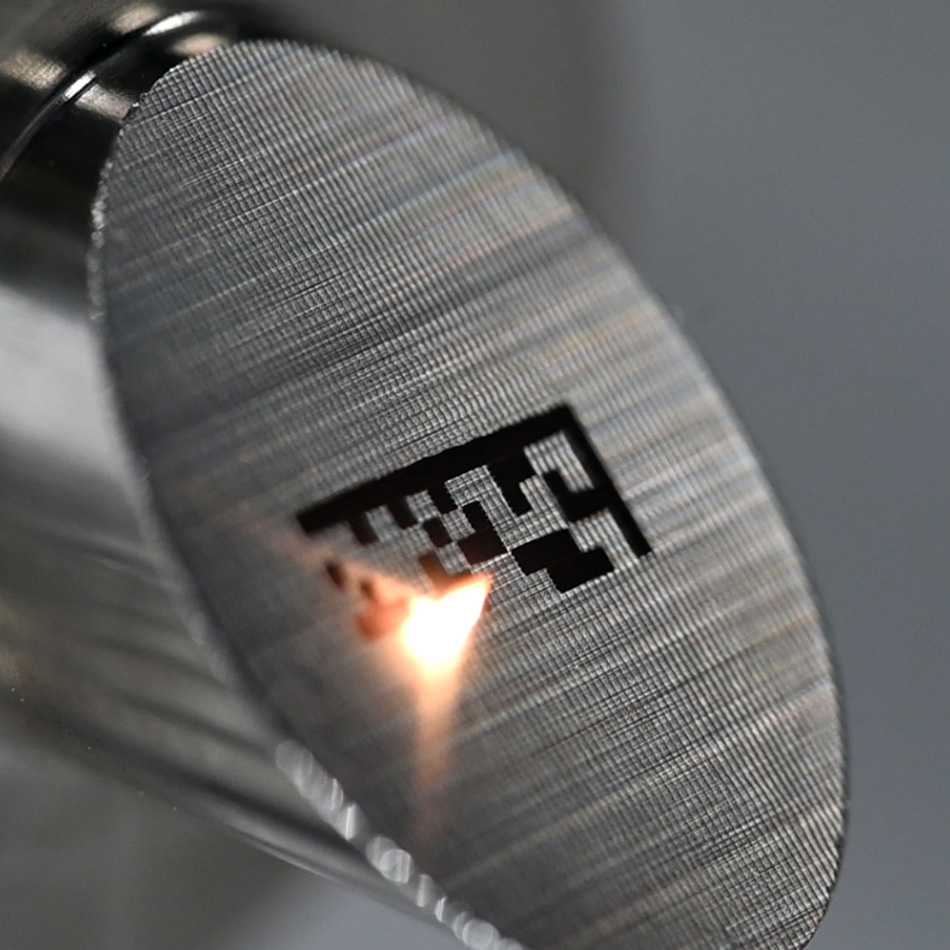

Laser marking is a precise and efficient method used for labeling various materials by altering the optical appearance of a surface or removing material. This process is a subset of laser material processing techniques and has gained significant popularity across multiple industries due to its accuracy and versatility.

Applications of Laser Marking

Laser marking is utilized in a wide range of applications, having evolved significantly over the decades. This technology is commonly used in industries for marking machine tools, printed circuit boards, integrated circuits, cables, keyboard buttons, credit cards, food packages, and bottles. These items often require unique labels such as model and serial numbers, logos, bar codes, and expiration dates.

The ability to add traceable information is crucial for quality control. For instance, in the semiconductor industry, silicon wafers can be marked with details about their origin, aiding in the identification and resolution of manufacturing issues.

Compared to traditional marking methods like inkjet printing and mechanical marking, laser marking offers numerous advantages. These include high processing speeds, low operational costs due to the absence of consumables, consistent quality, and durability. Additionally, laser marking prevents contamination, allows for tiny feature marking, and offers high flexibility in automation. However, the initial investment in laser marking machinery can be substantial.

Technical Details of Laser Marking

Mechanisms Used in Laser Marking

Laser marking employs various mechanisms to achieve desired results, including:

- Laser Engraving: This method involves using a laser to ablate the surface, creating a depth typically below 100 μm to achieve a clear visual appearance.

- Removing Surface Layers: The laser removes surface layers such as oxide or paint coatings, altering the surface’s appearance.

- Surface Modification: This involves altering the surface to change its visual appearance, such as forming thin oxide layers on metals or causing carbonization in polymers.

Scanning and Mask Methods

Marking patterns are created by moving a laser beam over the surface of the workpiece. This can be done using:

- Vector Methods: The laser beam draws contours of letters and digits for high-quality results.

- Systematic Scanning: Suitable for graphical patterns, this method involves scanning the entire area while disabling the laser in specific parts.

Alternatively, mask-based methods can be used, though they are less flexible and not as widely adopted today. These involve producing an entire label in one shot using a mask, which can be rapidly worn out and requires regular replacement. Scanning methods are increasingly preferred for their flexibility.

Laser Marking Machines

Laser marking machines typically consist of a pulsed solid-state laser, a compact beam delivery system, and auxiliary components for fume removal. The machines often include mechanisms for inserting and aligning workpieces, with some setups allowing for “on-the-fly” marking. For safety, many machines are encapsulated to operate only when their doors are closed.

Different materials require specific types of lasers. For instance, CO2 lasers are suitable for marking plastics, wood, cardboard, paper, leather, and acrylic, while metallic surfaces benefit from lasers with wavelengths in the 1-μm region, such as Nd:YAG or fiber lasers. Laser powers generally range from 10 to 100 W, with higher powers used for increased throughput.

Demands on Lasers for Marking

Lasers used for marking must meet several demands, including:

- Appropriate Wavelength: Lasers should have a wavelength that ensures sufficient absorption by the marked material.

- Optical Peak Intensity: A certain intensity or fluence must be reached on the workpiece to achieve satisfactory results.

- High Pulse Repetition Rate: Fast processing requires a high pulse repetition rate, implying a certain average power.

- Compact Design: The laser setup should be compact and not require complex cooling arrangements.

- Cost-Effectiveness: The cost of ownership should be moderate, considering installation, maintenance, and lifetime.

- Robust Design: Industrial environments demand a robust laser design that can withstand mechanical vibrations and back-reflections.

The choice of laser type depends on the specific application requirements. For example, Q-switched vanadate lasers are ideal for high pulse repetition rates, while fiber lasers offer flexibility in pulse rates and train interruptions.

Conclusion

Laser marking is a versatile and efficient technology that offers significant advantages over traditional marking methods. Its ability to provide precise, durable, and contamination-free markings makes it an essential tool across various industries. As technology advances, laser marking continues to evolve, offering even greater flexibility and efficiency in industrial applications.

Source: ESSERT Robotics

Feel free to comment your thoughts.