Contents

Source: wissenschaft.de

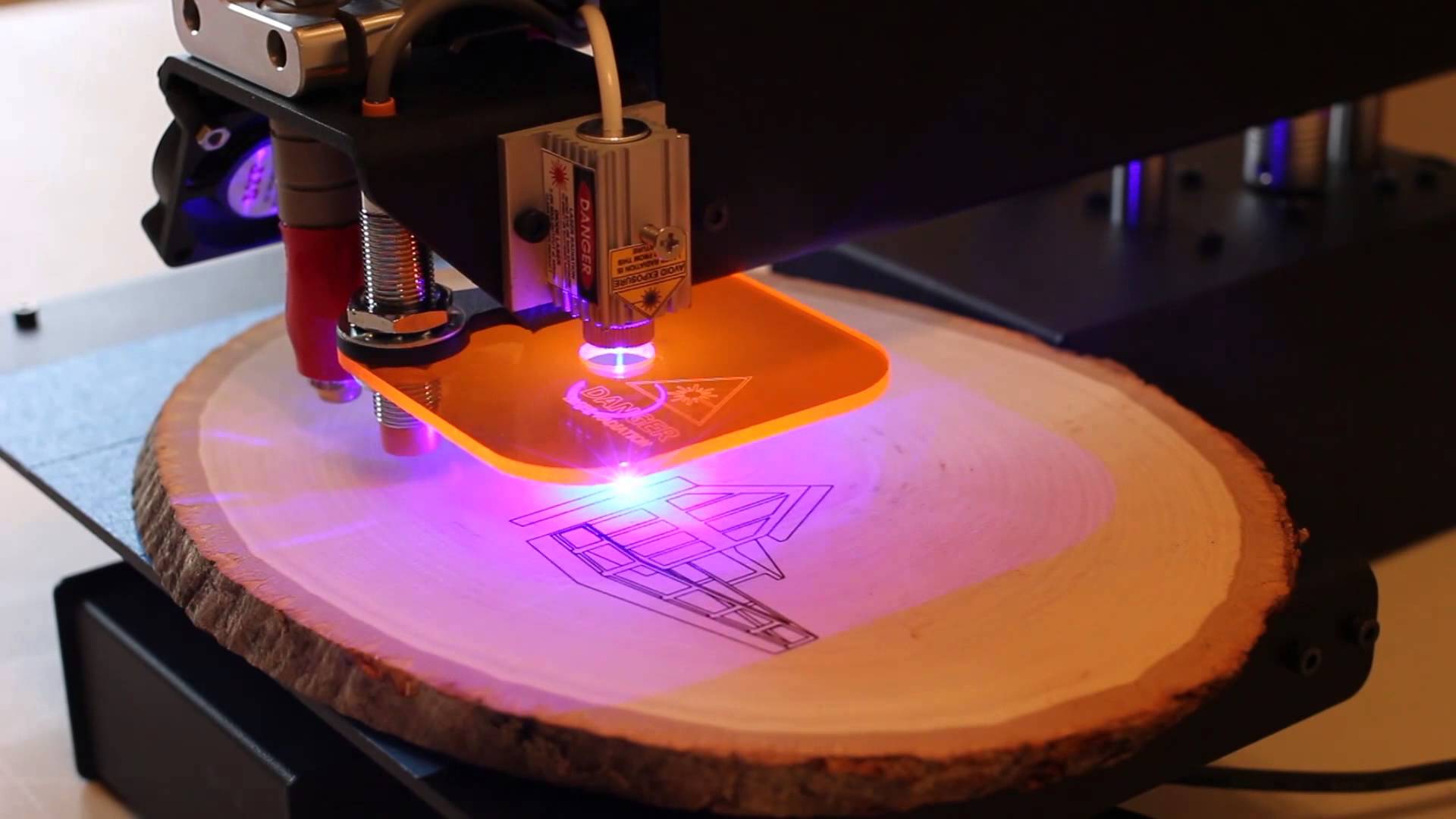

Understanding Laser 3D Printing

Laser 3D printing is revolutionizing the way we manufacture complex structures. From metals to polymers, this technology allows for the creation of intricate designs without the need for specialized tools. This blog post explores the principles, methods, materials, and applications of laser 3D printing.

Principles of Laser 3D Printing

Laser 3D printing, also known as stereolithography, involves using a laser to solidify a liquid or powder material. The process begins with a smooth surface of material, which is selectively irradiated by a laser beam to form a solid structure. This is repeated layer by layer until the desired object is formed.

Operation Process

The process involves a bath of liquid or powder material. A laser beam is directed over the surface, solidifying specific areas while leaving others untouched. This can be done using vector or raster methods, where the laser either follows specific lines or scans the entire area, respectively. The formed structure is then lowered, and a new layer of material is added, repeating the process until the object is complete.

Materials and Methods

Laser 3D printing can utilize a variety of materials, including metals, polymers, and ceramics. Each material requires specific processing techniques, such as selective laser melting for metals or laser-induced polymerization for polymers. The choice of material and method depends on the desired properties of the final product.

Metallic Structures

Metals like steel, nickel, titanium, and aluminum can be used in 3D printing. Processes such as selective laser melting and sintering are employed to form solid structures from metal powders. An inert gas is often used to prevent oxidation during the process.

Polymer and Ceramic Materials

Polymers can be processed using CO2 lasers, while ceramics are still in the developmental stage. For ceramics, a suspension of ceramic particles in a photo-curable binder can be used, with laser light initiating the curing process.

Applications of Laser 3D Printing

Laser 3D printing offers unprecedented design freedom, allowing for the creation of complex geometries that are difficult to achieve with traditional methods. It is widely used in rapid prototyping, tooling, and even direct manufacturing of parts.

Rapid Prototyping and Tooling

3D printing enables the quick production of prototypes and specialized tools. This is particularly useful for testing designs and creating custom tools for specific manufacturing processes.

Direct Manufacturing

In some cases, 3D printing is used for the direct fabrication of final parts, known as rapid manufacturing. This is ideal for producing small quantities of complex parts, such as medical implants and components for aerospace applications.

Challenges and Limitations

While laser 3D printing offers many advantages, it also has limitations. The range of usable materials is limited, and the processing time can be lengthy, especially for large parts. Additionally, the cost of raw materials and energy consumption can be higher compared to traditional manufacturing methods.

Material and Energy Considerations

The transformation of raw materials into a suitable form for 3D printing can be costly. Furthermore, the energy required for the process is significant, as each layer of material needs to be precisely processed.

Processing Time

The time required to produce parts can be a limiting factor, as the process is not as fast as traditional methods. However, the ability to create complex designs without specialized tools often outweighs this drawback.

In conclusion, laser 3D printing is a powerful tool in modern manufacturing, offering flexibility and design freedom that traditional methods cannot match. As technology advances, we can expect to see even more applications and improvements in this field.

Source: Geeetech

Feel free to comment your thoughts.