Contents

Source: Mergenthaler – Laser

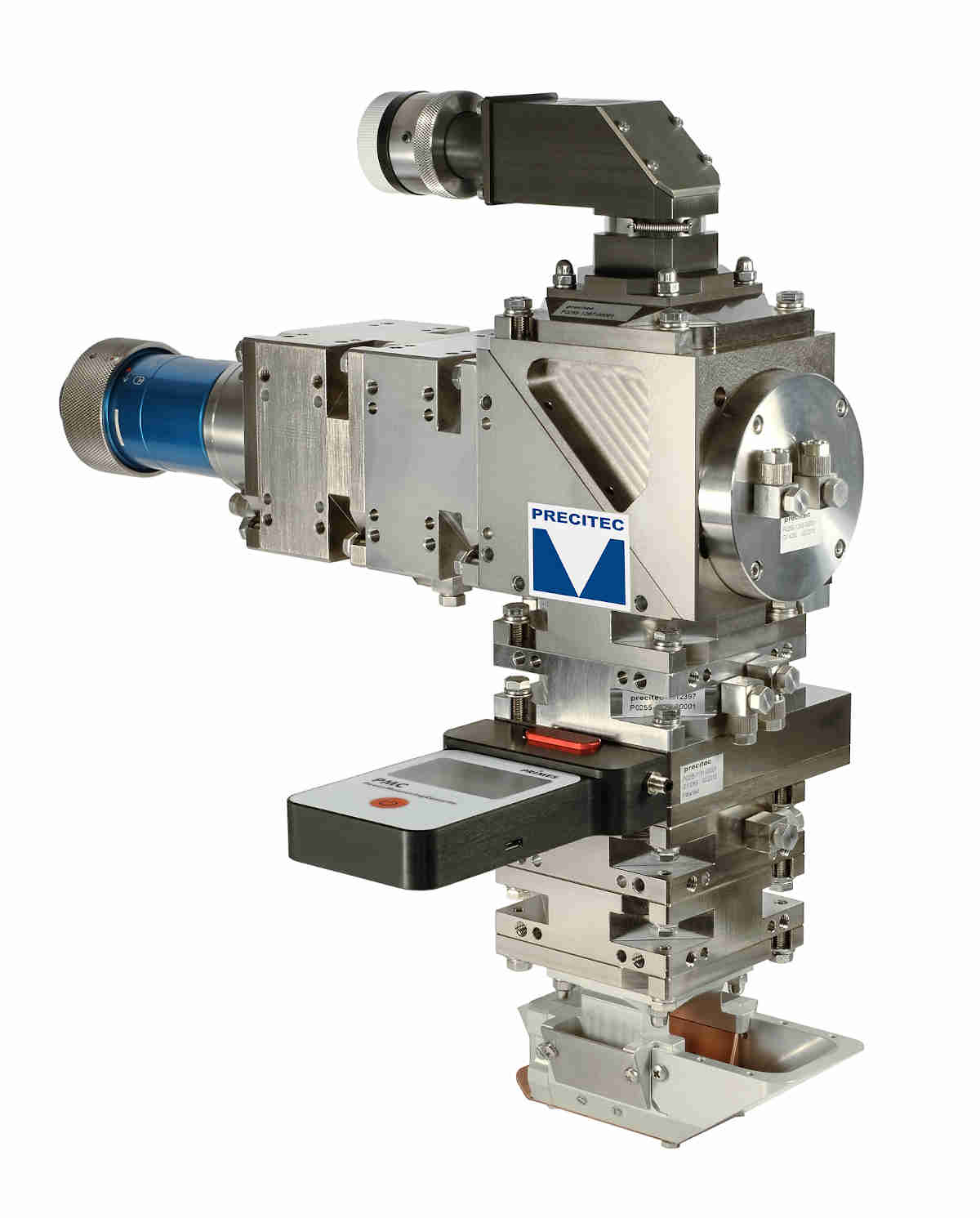

Understanding Laser Processing Heads in Industrial Applications

Laser processing heads play a crucial role in various industrial manufacturing processes, such as cutting, welding, and drilling. These heads are integral components of laser systems, directing focused laser beams onto workpieces to perform precise operations. This blog post explores the key functions, features, and considerations of laser processing heads.

Functions and Features of Laser Processing Heads

Beam Focusing

Focusing the laser beam onto a small spot on the workpiece is essential for achieving high optical intensities. Typically, the beam is collimated and then focused using a lens or curved mirror within the processing head. The choice between lenses and mirrors depends on power levels, with mirrors preferred for handling higher powers.

Beam Shutter

Beam shutters are used to temporarily block the laser beam, especially when the laser cannot be frequently switched on or off. These shutters can be integrated into the processing head or placed directly after the laser source.

Multiple Output Beams

Some processing heads can handle multiple beams, allowing simultaneous processing of different workpiece points or switching between beams with varying parameters. Techniques such as dual-spot and trifocal welding utilize multiple beams for enhanced process quality.

Working Distance

The working distance, or stand-off distance, is the gap between the processing head’s output and the workpiece surface. Depending on the application, this distance can be small for strong focusing or larger for remote operations like welding.

Beam Positioning and Scanning

Precise beam positioning is crucial, especially in micromachining. Some heads feature integrated scanners for beam direction adjustments, while others rely on moving the entire head or the workpiece. Rapid scanning can also generate diverse beam profiles.

Process Gas

Process gases, such as nitrogen or oxygen, are used in various laser processes to protect surfaces, enhance cutting, or blow away material. The gas can be delivered through nozzles or applied from the side, depending on the process requirements.

Material Feeds

In addition to process gas, some applications require solid material feeds, such as solder or powder. These materials can be delivered through nozzles or from the side, impacting the processing outcome.

Protecting the Optics

Optical components in laser processing heads are vulnerable to damage from debris and fumes. Protective measures include process gas, internal cross-jets, and anti-reflection coated windows to shield sensitive optics.

Power Handling

Processing heads must handle high optical powers without damage. Thermal effects and laser-induced damage are concerns, requiring careful design and the use of high-reflectivity mirrors.

Process Heads for Ultrafast Lasers

Ultrafast lasers, with pulse durations in the picosecond or femtosecond range, require specialized beam delivery systems. Conventional fiber cables are unsuitable due to high peak powers, necessitating the use of hollow-core fibers and achromatic optics for effective pulse transmission.

Specialized and Multipurpose Processing Heads

While many processing heads are optimized for specific tasks, multipurpose heads offer versatility with adjustable optics and interchangeable components. These heads can adapt to various processes, reducing the need for frequent head replacements.

Beam and Process Diagnostics

Integrated diagnostics are vital for maintaining process quality. Beam diagnostics monitor intensity profiles, while process diagnostics use cameras and sensors to assess process conditions and ensure high-quality results.

Conclusion

Laser processing heads are essential tools in industrial manufacturing, enabling precise and efficient operations. Understanding their functions, features, and requirements is crucial for optimizing laser-based processes and achieving superior outcomes.

Source: Precitec

Feel free to comment your thoughts.