Contents

Source: FindLight

Understanding Fiber and Bulk Lasers: A Comparative Analysis

Introduction

Lasers have become integral to various industries, from telecommunications to medical applications. Among the different types of lasers, fiber lasers and bulk lasers are often compared due to their overlapping application areas. This article explores the technical challenges, advantages, and potential applications of both laser types to provide insights into their respective strengths and weaknesses.

Technical Challenges of Fiber and Bulk Laser Devices

Basic Laser and Optical Properties

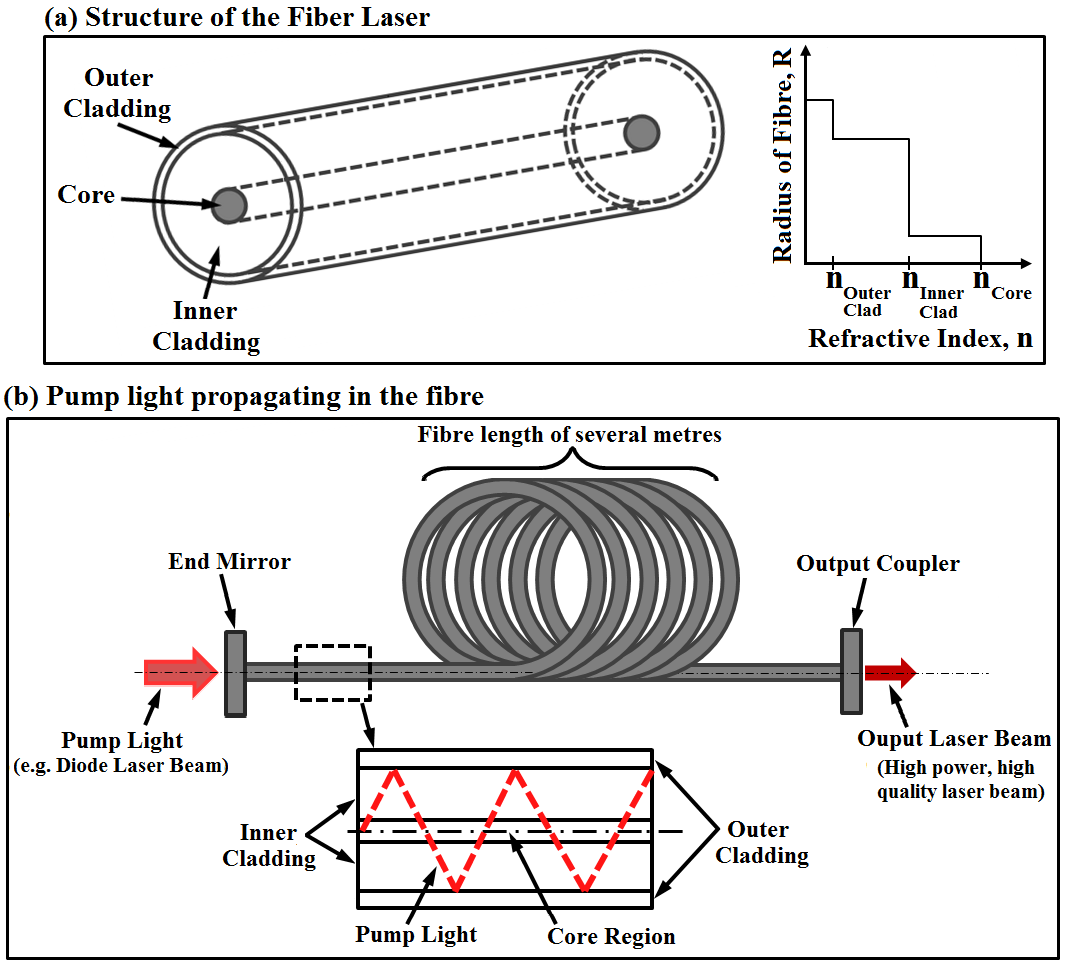

Fiber lasers, predominantly made of rare-earth-doped fibers, require long gain media due to moderate gain and pump absorption per unit length. This can lead to strong Kerr nonlinearities, affecting ultrashort pulse generation and single-frequency lasers. In contrast, bulk lasers, with smaller resonator losses, are more suitable for applications like intracavity frequency doubling.

Aspects Concerning High-power Devices

Both fiber and bulk lasers are capable of generating multi-kilowatt powers. Fiber lasers often exhibit higher power conversion efficiency but require high-quality pump sources, increasing the cost. Bulk lasers, particularly thin-disk lasers, can achieve higher single-mode powers but are more prone to thermal effects.

Short and Ultrashort Pulse Generation

Fiber lasers excel in generating high average powers with high beam quality, especially at unusual wavelengths. However, bulk lasers are superior for high pulse energies and peak powers, making them preferable for ultrashort pulse generation with a high pulse quality.

Sensitivity to Optical Feedback

High-power fiber devices are sensitive to optical feedback, which can lead to damage if not managed properly. While Faraday isolators can mitigate this issue, they are not always practical at high power levels. Bulk lasers, with larger mode areas, are less susceptible to such feedback problems.

Robustness and Cost

Fiber lasers, often constructed from inexpensive components, can be cost-effective and compact. However, the inclusion of air spaces and the need for precise alignment can reduce their robustness. Bulk lasers, while potentially more expensive, offer easier maintenance and component integration.

Uncertainties in Parameters

Developing laser systems can be challenging due to uncertainties in material parameters. Bulk lasers, using well-defined crystal materials, generally face fewer uncertainties compared to fiber lasers, which involve complex glass compositions and additional parameters like core diameter.

Conclusion

Both fiber and bulk lasers present significant benefits and drawbacks. Fiber lasers are ideal for applications requiring high average powers and beam quality, while bulk lasers excel in scenarios demanding high pulse energies and stability. The choice between these laser types depends on specific application requirements and performance criteria.

Further Reading

For more detailed information on laser technologies, consider exploring academic journals and industry publications that provide insights into recent advancements and applications in the field of photonics.

Source: MDPI

Feel free to comment your thoughts.