Contents

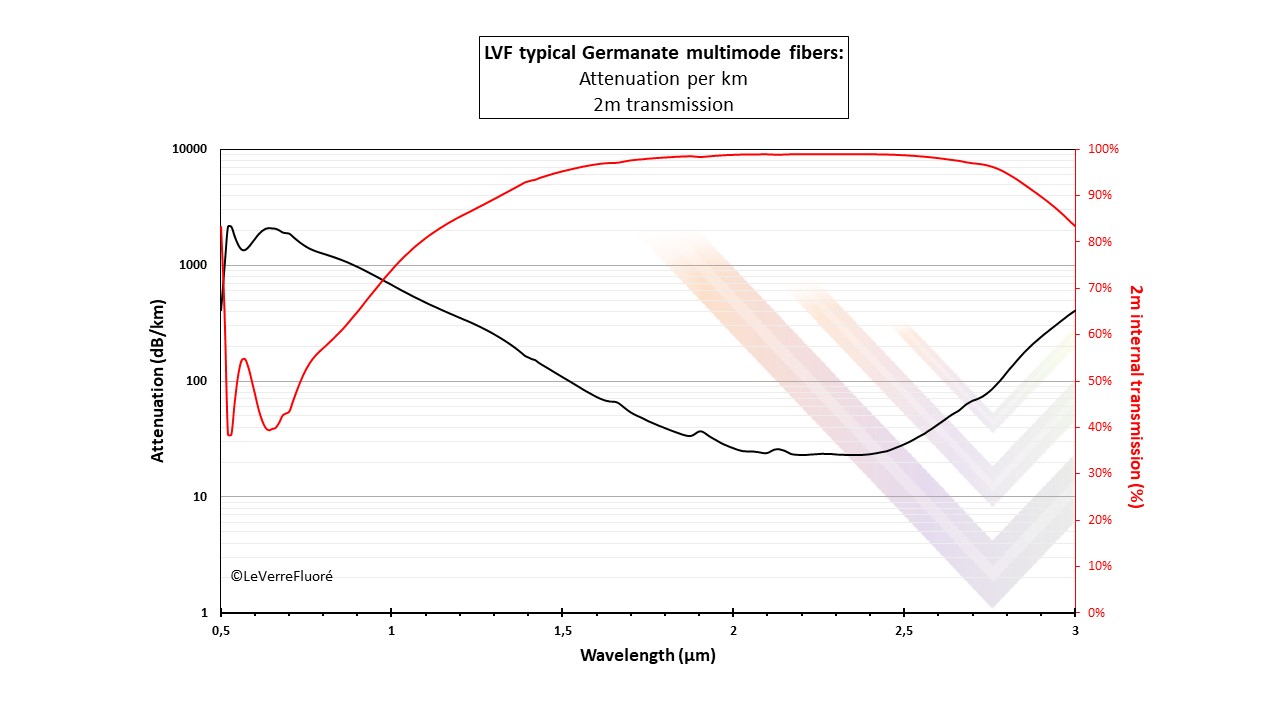

Source: Le Verre Fluore

Understanding Germanate Fibers in Photonics

Introduction to Germanate Fibers

Germanate fibers are a unique type of optical fiber that are primarily composed of germanate glasses. These glasses contain germanium oxide (GeO2) as a major component. Unlike germanosilicate fibers, which often have only a small portion of their silica replaced with germania, germanate fibers typically do not contain significant amounts of silica. This distinction is crucial in understanding the properties and applications of these fibers.

Chemical Composition and Properties

Germanium, the key element in germanate fibers, is chemically similar to silicon. Both are group-IV elements in the periodic table and form oxides. However, due to the heavier atomic weight of germanium, the vibration frequencies of Ge–O bonds are lower compared to those in silica. This characteristic extends the fiber’s transmission capabilities into the infrared spectral region, making them suitable for transmitting wavelengths up to approximately 3 μm or even 4 μm. This capability is particularly useful for transmitting 2.9-μm radiation from Er:YAG lasers.

Challenges with Infrared Transmission

While germanate fibers offer excellent infrared transmission, they are susceptible to degradation from hydroxyl content, particularly in the 2.4 μm to 3.6 μm range. This issue is common among oxide glasses and requires careful fabrication techniques to minimize hydroxyl content for optimal performance. One solution is the creation of fluorogermanate glasses with reduced OH− content, which are ideal for mid-infrared fiber applications.

Fabrication and Applications

In the production of optical fibers, the refractive index of the germanate glass can be increased by doping it with lead or other heavier elements. This process allows for the fabrication of both single-mode and multimode fibers. Additionally, the fiber core can be doped with laser-active ions such as Tm3+, enabling the creation of fiber amplifiers and lasers that operate at wavelengths around 1.7–2.1 μm.

Advanced Fabrication Techniques

Germanate glasses, known as “soft glasses,” have a low glass transition temperature, allowing for extrusion methods in the production of photonic crystal fibers with air holes. This technique results in a small effective mode area without requiring significant lead doping. The high nonlinear index of germanate glass also facilitates strong nonlinear effects, such as supercontinuum generation and Raman scattering, which are advantageous for various photonic applications.

Conclusion

Germanate fibers represent a significant advancement in the field of photonics, offering extended infrared transmission and the potential for various applications in laser technology and fiber optics. By understanding their chemical properties, fabrication methods, and application potential, researchers and engineers can continue to harness the unique advantages of germanate fibers in the development of advanced photonic systems.

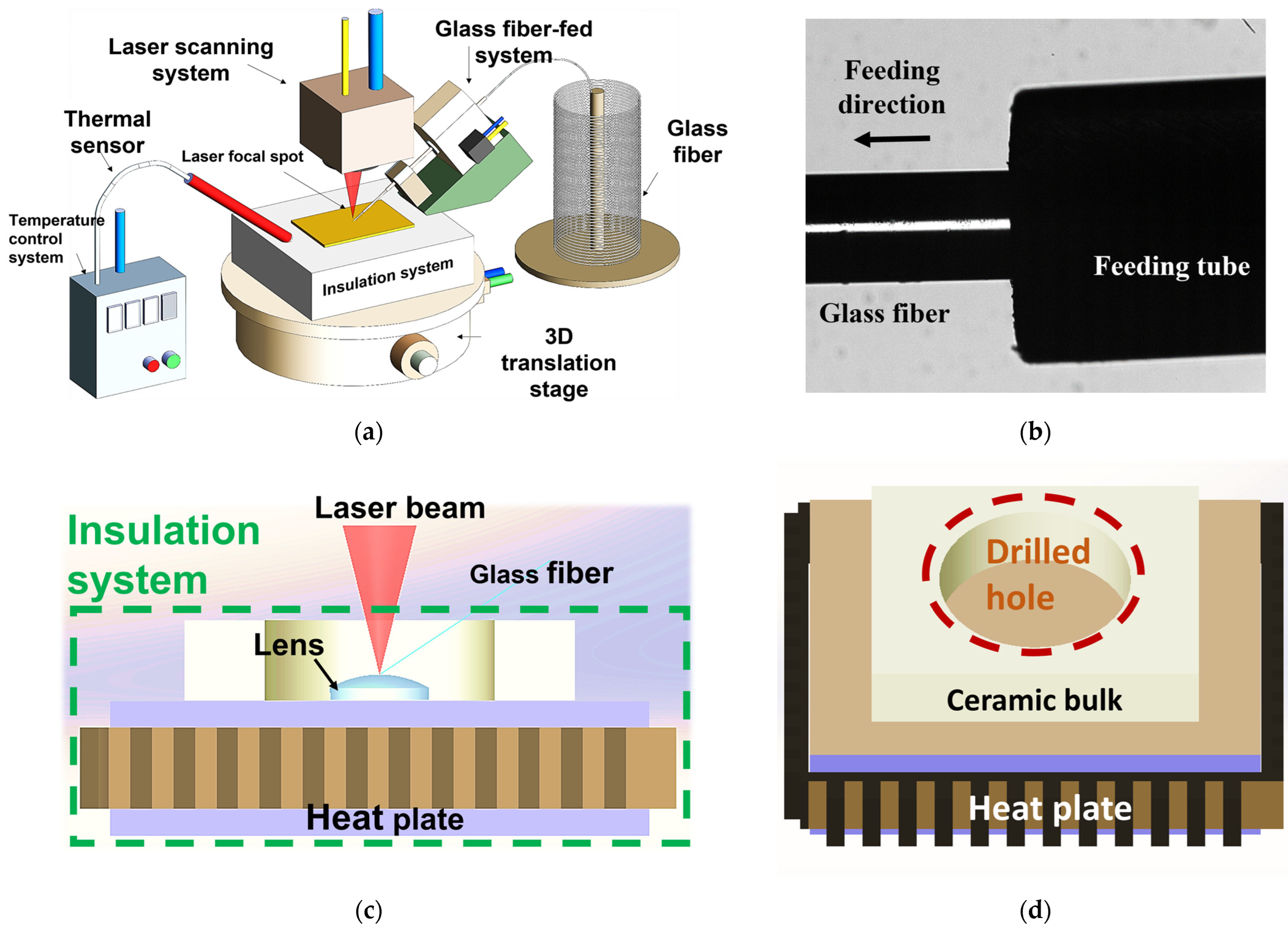

Source: MDPI

Feel free to comment your thoughts.