Contents

Source: Edmund Optics

Understanding the Cleaning and Maintenance of Optical Components

Optical elements and systems are critical components in many scientific and industrial applications. They are often operated in controlled environments to maintain their performance and longevity. However, there are instances when cleaning becomes necessary to prevent performance degradation or damage.

Why Clean Optical Components?

Despite being housed in clean environments, optical components can accumulate dust and dirt due to various reasons:

- Airborne Particles: Dust particles can settle on components from circulating air.

- Handling Contamination: Touching components with bare hands can leave residues.

- Laser Fumes: Intense laser beams can burn fumes onto surfaces.

Contaminants can lead to reduced performance and even permanent damage if not addressed, especially when exposed to intense laser beams.

Cleaning Procedures and Precautions

Proper cleaning techniques and equipment are essential to maintain the performance and integrity of optical components. Here are key considerations:

Assessing the Need for Cleaning

Not all optical components require perfect cleanliness. For instance, minor dust on a camera lens may not affect image quality significantly. However, components in laser systems or interferometers require meticulous cleaning to avoid performance issues.

Preventing Contamination

Preventing contamination is the best strategy. Here are some preventive measures:

- Encapsulate sensitive setups to prevent dust ingress.

- Designate clean areas for inspection and maintenance.

- Use clean clothing and tools when handling optical components.

- Store components in clean, protective environments.

Handling and Storage

When handling optical components, use gloves and touch only non-optical surfaces. Store components in clean tissues or bags to prevent scratches.

Cleaning Techniques

Using Compressed Air

Compressed air can effectively remove lightly attached particles. Use specialized devices to avoid contaminating surfaces with saliva or other residues.

Cleaning Lenses and Filters

Most lenses and filters are made of robust glass and can be cleaned using appropriate solvents and soft tissues. Solvents like isopropyl alcohol and acetone are effective for removing fingerprints and oils.

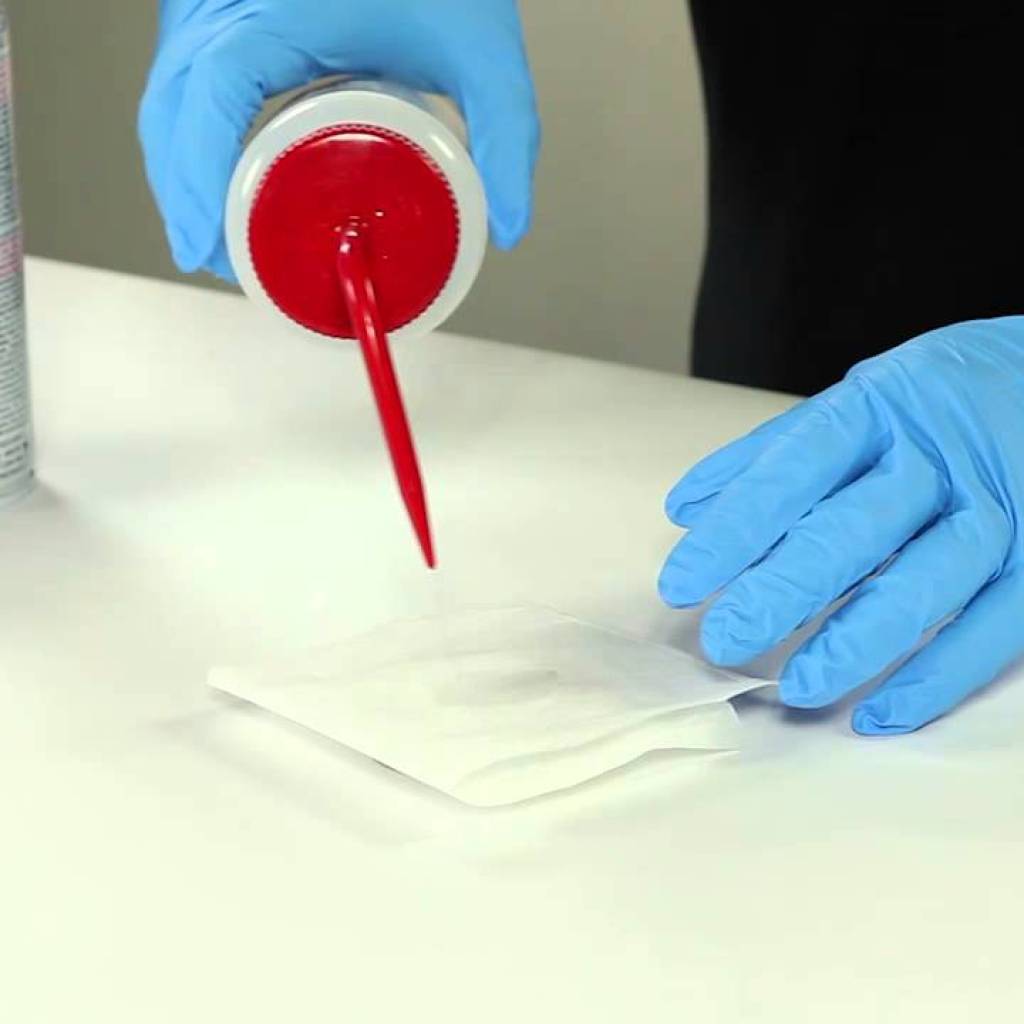

Cleaning Laser Mirrors

Laser mirrors are more sensitive and require careful cleaning. The drop-and-drag method, using a solvent-soaked tissue, is a common technique.

Ultrasonic Cleaning

Ultrasonic cleaning involves immersing components in a solvent and exposing them to ultrasound. This method is effective but may be too harsh for delicate components.

Conclusion

Maintaining optical components involves a balance between cleanliness and care. Proper handling, storage, and cleaning techniques ensure optimal performance and longevity. By understanding and implementing these practices, you can significantly extend the life of your optical systems.

This document provides a comprehensive overview of cleaning and maintaining optical components, focusing on the importance of cleanliness, preventive measures, and appropriate cleaning techniques. The content is structured with clear headings and subheadings, making it easy to navigate and understand.

Source: YouTube

Feel free to comment your thoughts.