Contents

Source: LIGHT CONVERSION

Understanding Fiber Cleaving in Optics

Introduction

Fiber cleaving is a crucial technique in the field of fiber optics, essential for preparing optical fiber ends for various applications such as splicing, connectorization, and light launching. The goal is to achieve clean, flat surfaces that are perpendicular or at a specific angle to the fiber axis, ensuring optimal performance.

The Fiber Cleaving Process

The process of fiber cleaving involves a controlled breakage of the glass fiber. Initially, a small fracture is made using a sharp tool like a diamond or ceramic blade. This is followed by applying tension or bending the fiber, causing it to break cleanly at the fracture point. This method typically results in smooth, high-quality surfaces.

Preparation and Tools

Before cleaving, the fiber’s protective coating must be removed using a coating stripper or a solvent in more challenging cases. Fiber cleaving tools, known as fiber cleavers, range from simple pen-shaped scribes to advanced mechanical precision splicers, the latter offering more consistent results but at a higher cost.

Challenges in Fiber Cleaving

Cleaving can be challenging with non-standard fibers, such as those with large diameters or unique compositions like fluoride or photonic crystal fibers. These cases may require adjustments in tension and technique, and sometimes even polishing if cleaving alone is insufficient.

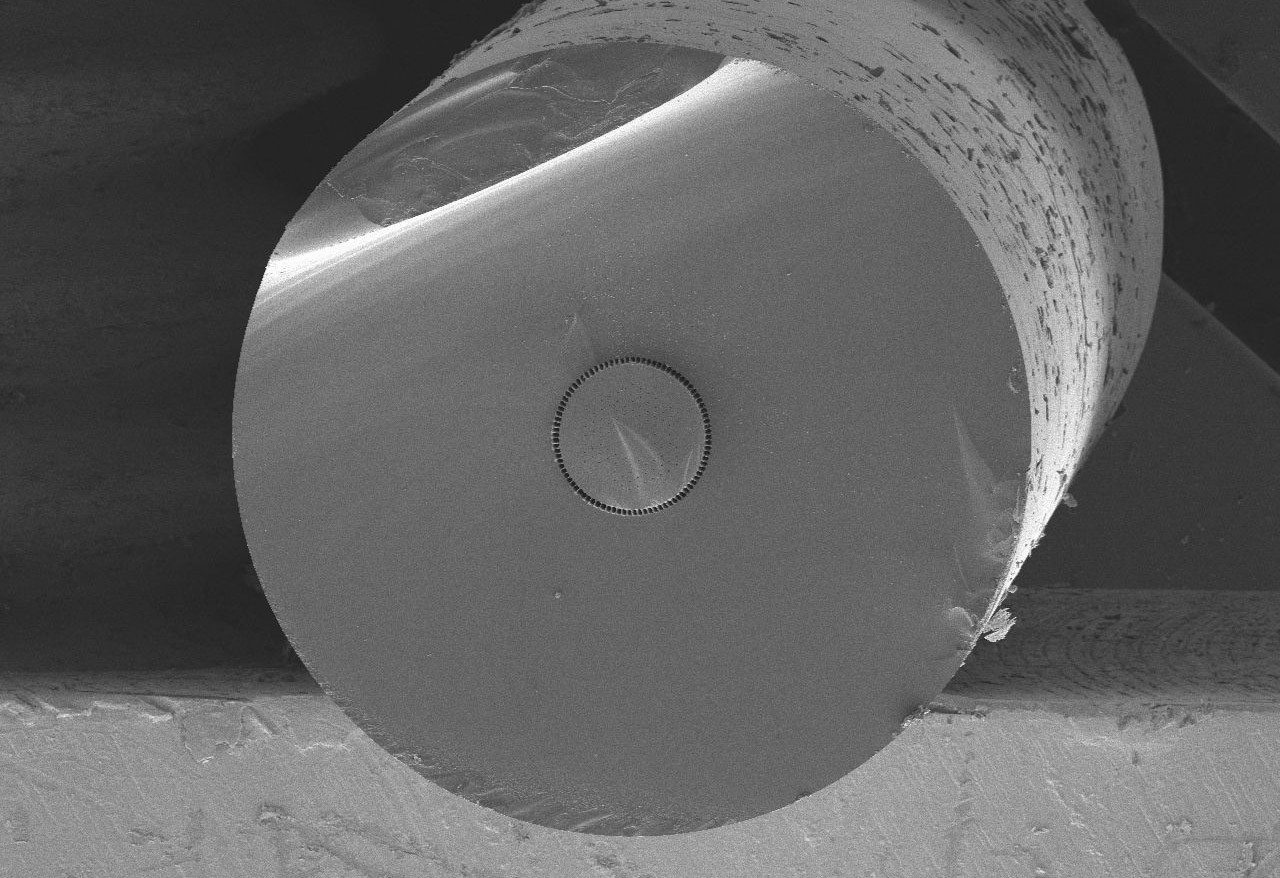

Evaluating Cleaving Quality

Quality assessment of cleaved fibers is critical and varies depending on the application. For splicing, surfaces should be perpendicular and smooth across the fiber. When launching or extracting light, smoothness over the fiber core is sufficient. Back-reflection-sensitive applications require precise cleave angles, while fiber lasers benefit from minimal angles to exploit Fresnel reflections.

Additional Treatment: Polishing

For superior surface quality, polishing may be necessary after cleaving. This involves inserting the fiber into a glass tube and polishing it for a precise orientation. Although time-consuming, this method ensures the highest quality surfaces.

Laser Cleaving of Fibers

Laser-based devices offer an alternative to mechanical cleaving, providing enhanced reliability and quality. Despite their higher cost, lasers are advantageous for processing fiber arrays quickly and consistently, reducing the need for subsequent polishing.

Safety Risks and Precautions

Cleaving generates sharp fiber scraps that pose safety risks, such as skin penetration or eye injuries. Proper disposal in marked containers and maintaining a clean work area are essential to prevent accidents.

Conclusion

Fiber cleaving is a fundamental process in fiber optics, requiring precision and the right tools to ensure optimal performance. Understanding the intricacies of cleaving, from preparation to evaluation, is essential for achieving high-quality results in various optical applications.

Source: Fraunhofer-Gesellschaft

Feel free to comment your thoughts.