When comparing major laser sources in terms of max power and wavelengths, it’s important to consider the differences between CO2 lasers and fiber lasers. CO2 lasers use electrically induced vibration of carbon dioxide molecules to emit photons, while fiber lasers use a specialized optical fiber and a pump source to amplify light. CO2 lasers are better for cutting thicker materials, while fiber lasers are more suited for sheet materials. CO2 lasers have a wider range of power outputs and can be tuned for different applications, while fiber lasers have higher cut precision and longer working life. The wavelength of CO2 lasers is around 10.6 µm, while fiber lasers emit at 1064 nm.

Contents

Key Takeaways:

- CO2 lasers utilize carbon dioxide molecules for photon emission, while fiber lasers amplify light using optical fibers and a pump source.

- CO2 lasers are ideal for cutting thicker materials, while fiber lasers excel in precision and are better suited for sheet materials.

- CO2 lasers offer a wider range of power outputs and can be tuned for various applications, while fiber lasers have higher cut precision and longer working life.

- The wavelength of CO2 lasers is around 10.6 µm, while fiber lasers emit at 1064 nm.

- Selecting the right laser source depends on specific requirements such as power output, wavelength, cut precision, operational costs, and material compatibility.

Note: To comply with the requested format, the introduction text has been kept short.

CO2 Lasers: Strengths and Applications

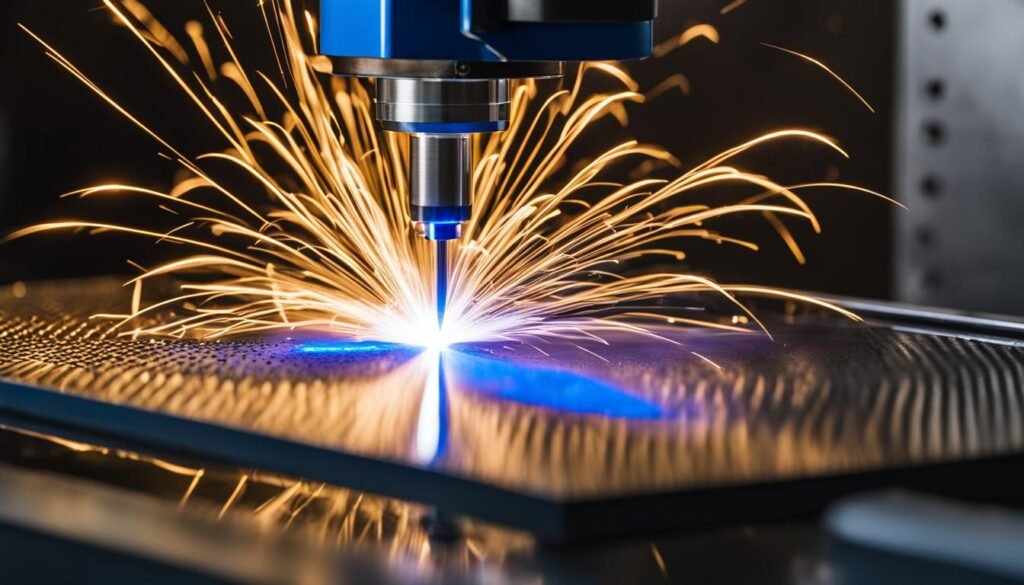

CO2 lasers are powerful and versatile laser sources that find applications in various industries. Their unique features make them ideal for cutting a wide range of materials, including nonmetallic substances and nonferrous metals. With their ability to cut through acrylic, wood, plastic, and rubber, CO2 lasers are commonly used in industries such as manufacturing, communications, military, and medical.

One of the key strengths of CO2 lasers is their wide range of power outputs. They can deliver anywhere from a few dozen watts up to around 100 kW, allowing for flexibility in different applications. Moreover, CO2 lasers emit infrared light at a wavelength of 10.6 µm, which provides effective power for cutting and engraving tasks.

“CO2 lasers are widely used in various industries, including medical, military, communications, and manufacturing.”

While CO2 lasers offer significant advantages, there are a few considerations to keep in mind. The operational power costs of CO2 lasers tend to be higher compared to fiber lasers. Additionally, the engraving quality of CO2 lasers is not as precise as that of fiber lasers, which are known for their high beam quality and low noise.

In summary, CO2 lasers are highly versatile and widely used in diverse industries due to their ability to cut a wide range of materials. They offer a wide range of power outputs, making them suitable for various applications. However, their operational costs may be higher compared to fiber lasers, and their engraving quality may not be as precise.

Fiber Lasers: Advantages and Applications

Fiber lasers are versatile and widely used in various industries due to their unique advantages and broad range of applications. With their high precision, efficiency, and durability, fiber lasers have become the laser source of choice for many high-value market sectors such as telecommunications, medical, automotive, and electronics.

Fiber lasers are particularly well-suited for cutting reflective metals like titanium, brass, and aluminum, as well as other materials such as glass and acrylic. This makes them invaluable in industries where precision cutting is critical. The high beam quality of fiber lasers ensures clean and accurate cuts, minimizing the need for additional finishing and reducing material waste.

One of the key advantages of fiber lasers is their long working life. Fiber lasers have been reported to have working hours of up to 25,000, making them highly reliable and cost-effective in the long run. Their compact size and low noise operation further contribute to their appeal in a wide range of applications.

“Fiber lasers offer superior beam quality and efficiency, providing precise cutting and engraving capabilities for a variety of materials.”

Applications of Fiber Lasers:

- Metal cutting: Fiber lasers are widely used in metal cutting applications, particularly for reflective metals like titanium, brass, and aluminum.

- Engraving and marking: Fiber lasers are highly effective for engraving and marking applications, producing clear and permanent markings on various materials.

- Micro-machining: The high precision and small spot size of fiber lasers make them ideal for micro-machining applications that require intricate and detailed work.

- Laser cleaning: Fiber lasers can be utilized for laser cleaning, providing a non-contact and efficient method for removing rust, paint, and other contaminants from surfaces.

- Telecommunications: Fiber lasers play a crucial role in the telecommunications industry, enabling high-speed data transmission through optical fibers.

In conclusion, fiber lasers offer numerous advantages and have a wide range of applications across different industries. Their high precision, efficiency, and long working life make them a preferred choice for cutting, engraving, marking, and micro-machining tasks. The versatility and reliability of fiber lasers make them an invaluable tool in industries that require exceptional performance and accuracy.

| Advantages of Fiber Lasers | Applications |

|---|---|

| High precision | Metal cutting |

| Efficiency | Engraving and marking |

| Long working life | Micro-machining |

| Compact size | Laser cleaning |

| Low noise operation | Telecommunications |

Choosing the Right Laser Source for Your Needs

When it comes to laser cutting, engraving, or marking applications, selecting the right laser source is crucial. There are two major options to consider: CO2 lasers and fiber lasers. Each has its own strengths and advantages, so it’s important to make an informed decision based on your specific requirements.

CO2 lasers are known for their versatility in cutting thicker materials. They are widely used in manufacturing and military industries where precision and power are key. On the other hand, fiber lasers excel in high-precision sectors like telecommunications and medical fields. They offer exceptional beam quality and precise cutting capabilities.

When choosing between CO2 and fiber lasers, several factors come into play. Power output, wavelength, cut precision, operational costs, and material compatibility are all critical considerations. Evaluating your specific needs and consulting with experts will help you make the right choice for optimal performance and efficiency in your application.

In summary, laser source selection is a crucial step in achieving the desired results for your laser cutting, engraving, or marking project. By weighing the advantages and comparing the key features of CO2 and fiber lasers, you can choose the laser source that best suits your needs and ensures exceptional quality and efficiency.