Contents

Laser technology has revolutionized various industries, offering precise and efficient solutions for a wide range of applications. Among the different types of lasers available, continuous wave lasers stand out for their constant output and versatility. Whether it’s cutting, welding, medical procedures, or scientific research, continuous wave lasers have become an invaluable tool in many fields.

Key Takeaways:

- Continuous wave lasers provide a constant output of monochromatic light.

- They are utilized in industries such as medical, fabrication, and scientific research.

- Continuous wave lasers offer stability and precision for various applications.

- They differ from pulsed lasers in terms of emission characteristics.

- Continuous wave lasers are efficient and find applications in diverse fields.

What is a Continuous Wave Laser?

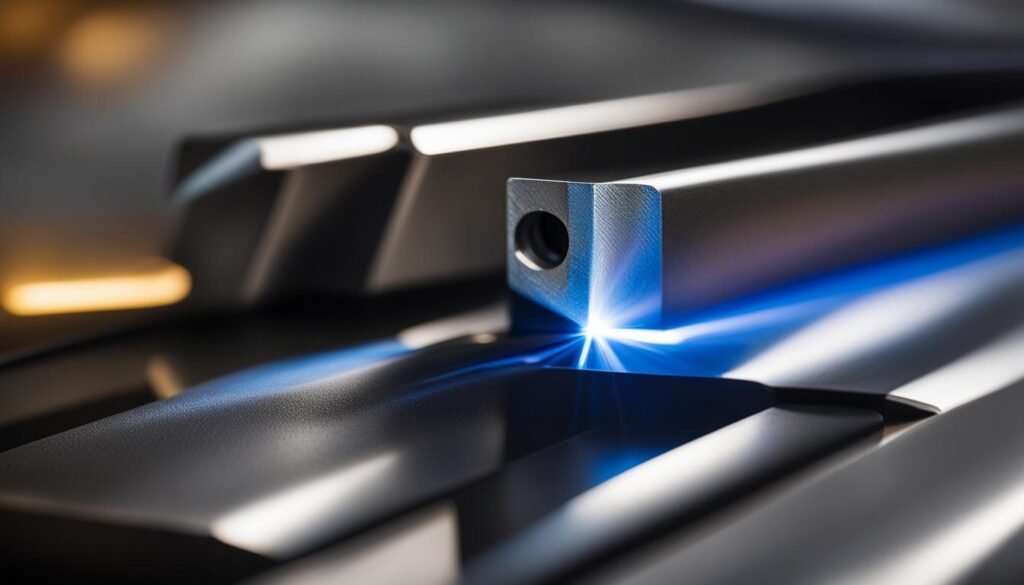

A continuous wave laser is a type of laser that emits a constant output of monochromatic light. It is commonly referred to as a CW laser. Unlike pulsed lasers that emit light in short bursts, continuous wave lasers provide a steady and uninterrupted beam. This makes them ideal for applications that require a constant and stable source of light.

The wavelength of a continuous wave laser is determined by the gain medium used. This can include synthetic ruby, titanium-sapphire, neodymium-doped yttrium aluminium garnet (Nd:YAG), or fiber. The specific gain medium determines the laser’s wavelength, which can range from visible light to ultraviolet or infrared. Continuous wave lasers offer a wide range of output options, allowing for versatility in various applications.

“Continuous wave lasers provide a stable and consistent output, making them highly reliable for a wide range of applications.”

Continuous wave lasers are widely used in fields such as medical, industrial, and scientific research. Their constant output and stable performance make them suitable for precision tasks such as laser microsurgery, spectroscopy, and material processing. Additionally, continuous wave lasers are utilized in telecommunications, entertainment, and environmental monitoring, among other applications.

| Advantages of Continuous Wave Lasers | Applications |

|---|---|

|

|

Continuous wave lasers provide a stable and consistent output, making them highly reliable for a wide range of applications. Their versatility and efficiency make them an invaluable tool in laser technology, enabling precise and controlled operations in various industries.

Continuous Wave Lasers vs. Pulsed Lasers

The use of lasers in various industries has revolutionized many processes and applications. When it comes to laser technology, there are different types of lasers available, each with its own unique characteristics. Two common types of lasers are continuous wave lasers and pulsed lasers. Let’s take a closer look at the differences between them.

Laser Stability

Continuous wave lasers are known for their stability and consistent power output. They emit a continuous beam of light without interruption, which makes them ideal for applications that require long operating periods. In contrast, pulsed lasers emit light in short bursts, providing high intensity in a shorter timeframe. This makes pulsed lasers suitable for applications that require precise control over energy delivery or when rapid material processing is needed.

Laser Efficiency

Continuous wave lasers are highly efficient because they provide a constant output over a set interval. This allows for better control of the energy delivered, leading to more precise results. Pulsed lasers, on the other hand, can be more efficient in terms of energy usage since they only emit light in short pulses. However, the overall efficiency of a laser system depends on the specific application and the desired outcome.

It’s important to note that both continuous wave lasers and pulsed lasers have their advantages and are used in various industries depending on the specific requirements of the application. Continuous wave lasers are favored for their stability and constant power output, making them suitable for industrial processes that require prolonged operation. Pulsed lasers, on the other hand, excel in applications that require high intensity and rapid processing. Ultimately, the choice between continuous wave lasers and pulsed lasers depends on the specific needs and goals of the user.

| Continuous Wave Lasers | Pulsed Lasers | |

|---|---|---|

| Stability | High | Varies depending on pulse duration |

| Power Output | Constant | Varies depending on pulse duration |

| Efficiency | High | Varies depending on pulse duration |

| Applications | Industrial processes, cutting, welding | Rapid material processing, laser ablation |

Applications of Continuous Wave Lasers

Continuous wave lasers, with their steady and precise output, find a wide range of applications across different industries. Their versatility and efficiency make them invaluable tools for various tasks and processes. Let’s explore some of the key applications of continuous wave lasers:

Material Processing:

Continuous wave lasers are extensively used in material processing industries for cutting, welding, and drilling. Their constant output and stable beam provide precise control, ensuring clean and accurate results. Whether it’s shaping metals, plastics, or other materials, continuous wave lasers offer unparalleled precision and efficiency.

Medical and Biomedical Applications:

In the medical field, continuous wave lasers have proven to be highly beneficial. They are utilized in surgical procedures, such as laser eye surgery and skin treatments. Continuous wave lasers also play a significant role in sealing blood vessels during surgery, reducing bleeding and accelerating healing. Furthermore, their precise control allows for targeted treatment of various skin conditions, offering patients improved outcomes.

Telecommunications and Spectroscopy:

Continuous wave lasers are an integral part of the telecommunications industry. They are utilized in fiber optic communications to transmit data over long distances with minimal loss. Additionally, continuous wave lasers are essential in spectroscopy, enabling scientists to analyze the interaction between light and matter. This has wide-ranging applications in fields such as chemistry, physics, and environmental monitoring.

Scientific Research and Entertainment:

Continuous wave lasers are widely employed in scientific research for their stability and versatility. They provide researchers with a reliable light source for conducting experiments and measurements. In the entertainment industry, continuous wave lasers are utilized in laser light shows, creating captivating visual effects and mesmerizing audiences.

Continuous wave lasers, with their broad range of applications, have become indispensable tools in various industries. Whether it’s cutting and welding, medical procedures, scientific research, or entertainment, continuous wave lasers offer efficiency, precision, and reliability, driving progress and innovation in countless fields.

Conclusion

Continuous Wave Lasers are a key component of laser technology, offering efficiency and versatility in various applications. Their constant output and stability make them indispensable in industries such as material processing, medicine, telecommunications, and scientific research.

With their ability to deliver a steady beam of light, Continuous Wave Lasers ensure precise and reliable results, making them ideal for cutting, welding, drilling, surgery, and sealing blood vessels. Their efficiency and wide range of gain mediums enable them to be utilized in diverse fields, from entertainment to environmental monitoring.

As technology continues to advance, Continuous Wave Lasers will undoubtedly play an even larger role in innovation and progress. Their applications will expand further, propelling advancements in laser technology and driving improvements across industries. Continuous Wave Lasers are truly a powerful tool that continues to revolutionize laser applications.

FAQ

What is a continuous wave laser?

A continuous wave laser is a type of laser that emits a constant output of monochromatic light.

How does a continuous wave laser differ from a pulsed laser?

Continuous wave lasers emit an uninterrupted beam of light, while pulsed lasers emit light in short bursts.

What are the applications of continuous wave lasers?

Continuous wave lasers are used in cutting, welding, drilling, surgery, scientific research, telecommunications, and more.

How stable are continuous wave lasers?

Continuous wave lasers provide a steady and stable output, making them suitable for long operating periods in industrial applications.

Which industries benefit from continuous wave lasers?

Continuous wave lasers are used in industries such as material processing, medical and biomedical, telecommunications, spectroscopy, scientific research, entertainment, and environmental monitoring.