Contents

- 1 Understanding Custom Optical Elements and Systems

Source: Coherent

<>

Understanding Custom Optical Elements and Systems

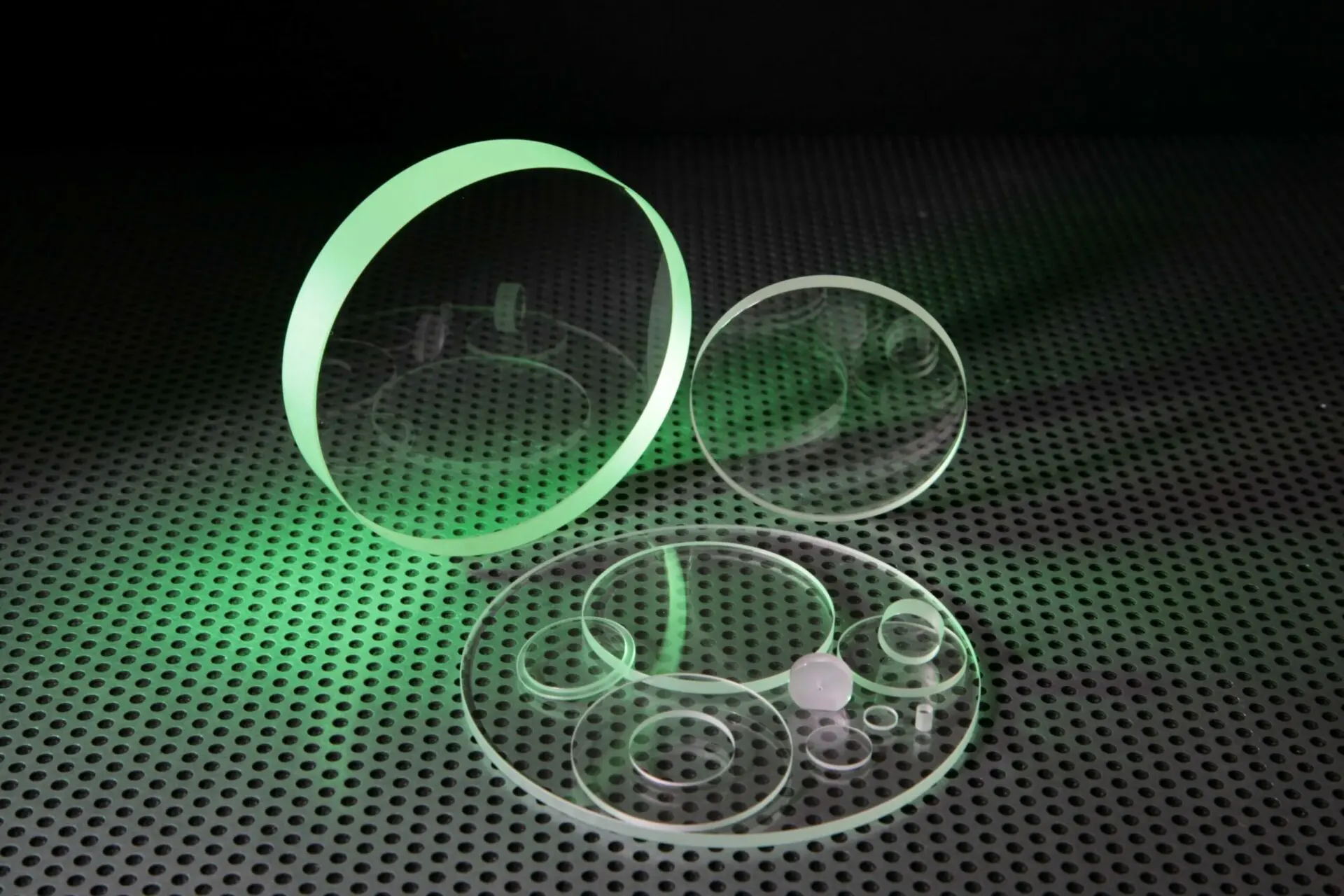

Custom Optical Elements

Custom optical elements are specifically designed and produced for individual customers who require unique specifications that standard parts cannot meet. Examples include lenses, laser mirrors, prisms, and diffraction gratings.

Turning Stock Optics into Custom Optics

Custom optical elements can sometimes be created by modifying stock optics. This can involve applying custom coatings, improving surface figures, or adjusting dimensions to fit specific requirements.

Sorted Optics

Manufacturers may identify optical elements that exceed standard specifications and sell them as custom precision parts to meet stricter requirements.

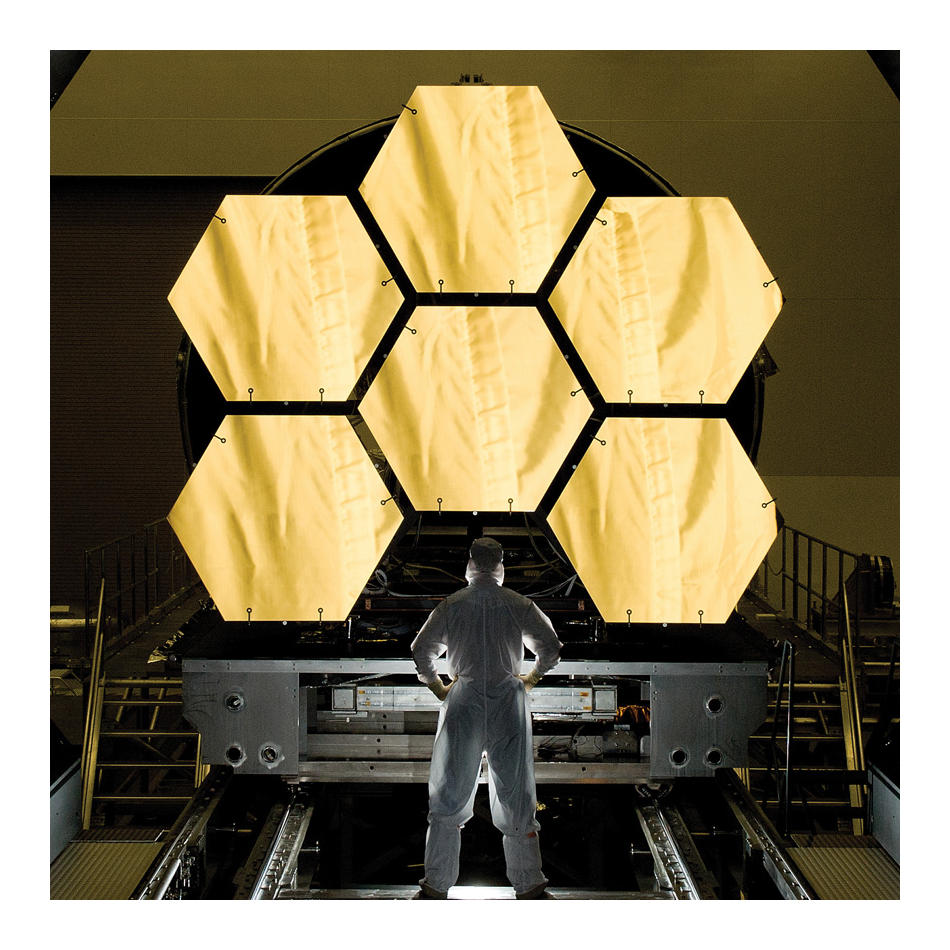

Custom Optical Systems

Complex optical arrangements, consisting of multiple elements, can be standard or custom-made. Custom optical systems may require custom optical elements or a combination of standard elements tailored to specific needs.

Components or systems with many essential parameters

Optical components or systems with numerous essential parameters are less likely to be found as standard optics. Custom solutions may be necessary to meet detailed requirements.

Using Standard vs. Custom Optics

While standard components are generally more cost-effective and readily available, custom optics are essential for applications with unique demands. Careful design and testing are crucial to minimize costs and delays associated with custom elements.

Cost Models for Custom Optics

Manufacturers may use special cost models for custom optics, including non-recurring charges for design, tooling, and specification refinement. Prices for custom optics depend on strictness of specifications and lead times.

Custom Optics Specialists

Specialized suppliers in areas like lenses or prisms can offer custom optics at competitive prices and superior performance due to their expertise and specialized equipment.

Custom Optical Assemblies as OEM Parts

Custom optical assemblies provided as OEM parts are designed and manufactured by a supplier and integrated into larger devices by a system integrator. The manufacturer assumes responsibilities for design, quality control, and support.

Specifications for Custom Optics

Agreeing on precise specifications with manufacturers is crucial when ordering custom optics. Detailed specifications help ensure the required performance and prevent over-tolerancing, especially in high-volume production.

Conclusion

Custom optical elements and systems play a vital role in meeting specialized requirements that standard optics cannot fulfill. While standard components offer cost and time advantages, custom solutions are indispensable for tailored applications. Clear specifications, collaboration with manufacturers, and thorough testing are key to successful implementation of custom optics.

Source: UQG Optics

Feel free to comment your thoughts.