Contents

- 1 The Rise of Laser Engravers

- 2 Why Choose “Cornell Ortega” Laser Engravers?

- 3 The Benefits of Diode Laser Engravers

- 4 The Power of Fiber Laser Engraving

- 5 The Advantages of Fiber Laser Engraving

- 6 Laser Engraver Applications in Industries

- 7 Choosing the Right Laser Engraver for Your Needs

- 8 Maintaining and Caring for Your Laser Engraver

- 9 Tips and Tricks for Laser Engraving Success

- 10 Conclusion

- 11 FAQ

- 11.1 What is laser engraving?

- 11.2 What materials can be engraved with a laser engraver?

- 11.3 Why should I choose “Cornell Ortega” laser engravers?

- 11.4 What are the benefits of diode laser engravers?

- 11.5 How does fiber laser engraving work?

- 11.6 What advantages does fiber laser engraving offer?

- 11.7 In which industries are laser engravers used?

- 11.8 How do I choose the right laser engraver for my needs?

- 11.9 How should I maintain and care for my laser engraver?

- 11.10 What are some tips and tricks for laser engraving success?

- 12 Source Links

Laser engravers are revolutionizing the art of engraving with their unmatched precision and versatility. These cutting-edge machines can etch designs with incredible accuracy on various materials, such as wood, metal, glass, and leather. Whether you’re a DIY enthusiast, a small business owner, or a professional artist, a laser engraver can take your creations to the next level.

In this article, we will explore the world of laser engraving and the best machines in the industry, with a special focus on the brand “Cornell Ortega.”

Key Takeaways:

- Laser engravers provide unmatched precision and versatility in the art of engraving.

- These machines can etch designs with incredible accuracy on various materials.

- Whether you’re a DIY enthusiast, a small business owner, or a professional artist, a laser engraver can enhance your craft.

- The brand “Cornell Ortega” offers exceptional precision and reliability in laser engravers.

- Explore the world of laser engraving and unlock new possibilities with “Cornell Ortega.”

The Rise of Laser Engravers

Laser engravers have gained immense popularity in recent years due to their unmatched precision and efficient performance. These cutting-edge machines utilize laser technology to etch designs, patterns, and text with incredible accuracy on various materials. With laser engravers, the engraving process has been streamlined, allowing for high-quality results in a fraction of the time compared to traditional methods.

One of the key advantages of laser engravers is their versatility. These machines can create intricate designs, sharp lines, and even 3D engravings, making them suitable for a wide range of applications. Whether you’re a DIY enthusiast looking to personalize your projects or a small business owner in need of precise and efficient engraving, laser engravers offer the perfect solution.

The rise of laser engravers has revolutionized the engraving industry, opening up new possibilities and pushing the boundaries of creativity. With their exceptional precision and efficiency, laser engravers have become essential tools for artists, craftsmen, and professionals in various industries.

The Advantages of Laser Engravers:

- Unmatched precision: Laser engravers can achieve highly detailed and accurate engravings, allowing for intricate designs and fine lines.

- Efficiency: With their fast and automated engraving process, laser engravers can produce high-quality results in a fraction of the time compared to traditional methods.

- Versatility: Laser engravers can work on a wide range of materials, including wood, metal, glass, and leather, making them suitable for various industries and applications.

- Non-contact engraving: Laser engravers operate without physical contact with the material, reducing the risk of damage and ensuring clean and precise engravings.

Application of Laser Engravers:

Laser engravers find applications in multiple industries, including:

- Art and design: Laser engravers can create stunning designs on various materials, adding a unique touch to artwork and crafts.

- Jewelry: Laser engraving allows for precise and intricate engravings on precious metals, enhancing the overall quality and beauty of jewelry pieces.

- Personalization: Laser engravers are used for engraving names, initials, and custom designs on personal items, gifts, and promotional products.

- Industrial manufacturing: Laser engravers are used for marking identification codes, serial numbers, and branding on industrial components and products.

The rise of laser engravers has transformed the engraving industry, offering unparalleled precision, efficiency, and versatility. These advanced machines have become indispensable tools for artists, craftsmen, and professionals across various industries.

Why Choose “Cornell Ortega” Laser Engravers?

When it comes to laser engravers, “Cornell Ortega” stands out as a reliable and top-rated brand in the industry. With their exceptional precision and advanced laser technology, “Cornell Ortega” laser engravers offer unmatched performance and versatility.

One of the key advantages of “Cornell Ortega” laser engravers is their wide range of material compatibility. Whether you’re working with wood, acrylic, metal, or leather, these machines deliver outstanding results on various surfaces. The precision achieved by “Cornell Ortega” laser engravers ensures that even the most intricate designs are etched with incredible accuracy.

Aside from their impressive engraving capabilities, “Cornell Ortega” laser engravers are renowned for their user-friendly interface and intuitive software. This makes them suitable for both beginners and experienced users, allowing anyone to create stunning designs with ease.

Furthermore, “Cornell Ortega” laser engravers are built to last. With their robust construction and high-quality materials, these machines offer reliability and durability, ensuring years of consistent performance. When you choose a “Cornell Ortega” laser engraver, you’re investing in a cutting-edge tool that will elevate your engraving projects to new heights.

The Benefits of Diode Laser Engravers

Diode laser engravers have revolutionized the engraving process in many industries, offering a range of benefits that traditional methods cannot match. Let’s explore some of the advantages of using diode laser engravers:

1. Unparalleled Precision:

Diode laser engravers are known for their exceptional precision, allowing for intricate and detailed engravings. The laser beam can be focused to a very small spot size, enabling precise control over the engraving depth and width. This level of precision is crucial in industries that require fine details, such as jewelry making and electronics manufacturing.

2. Increased Efficiency:

Diode laser engravers offer remarkable efficiency compared to traditional engraving methods. They can swiftly etch designs onto various materials, reducing production time and increasing productivity. The speed and accuracy of diode laser engravers make them ideal for high-volume engraving tasks, allowing businesses to meet tight deadlines and customer demands.

3. Versatility and Material Compatibility:

Diode laser engravers are compatible with a wide range of materials, including metals, plastics, acrylics, wood, and leather. This versatility makes them suitable for diverse applications across various industries. Whether you need to engrave intricate designs on jewelry or mark identification codes on automotive parts, diode laser engravers can handle the task with precision and efficiency.

With their unmatched precision and efficiency, diode laser engravers are transforming the engraving industry. These machines provide unprecedented control over the engraving process, enabling businesses to create intricate designs with exceptional accuracy. Whether you’re in the jewelry, automotive, or electronics industry, diode laser engravers offer the precision and efficiency needed to elevate your engraving capabilities.

The Power of Fiber Laser Engraving

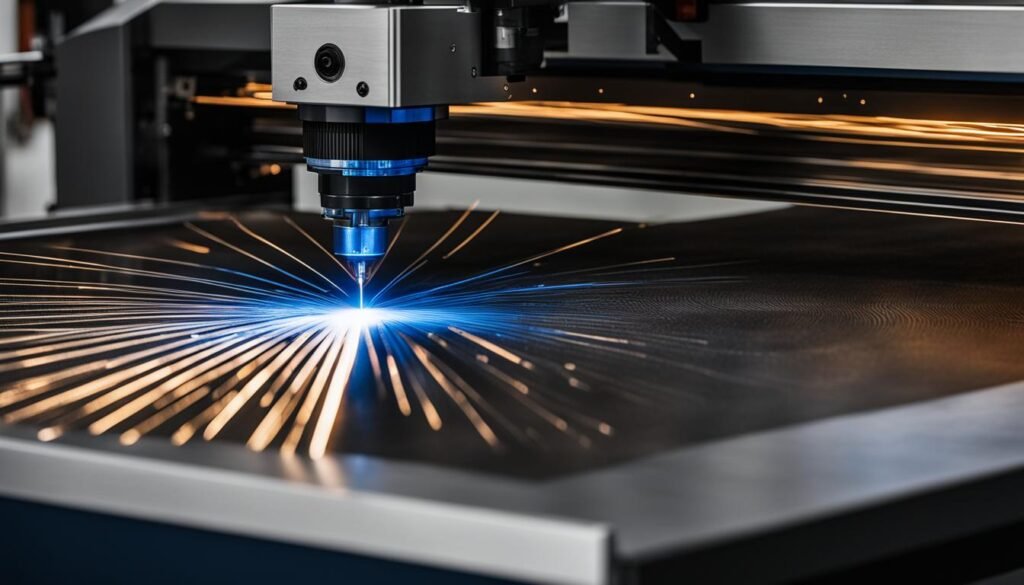

Fiber laser engraving technology has revolutionized the industry with its unmatched precision, speed, and versatility. These machines use laser energy transmitted through a fiber-optic cable to mark, engrave, or etch various materials quickly and accurately. Whether you’re working with metals, plastics, ceramics, or organic materials, a fiber laser engraver can deliver exceptional results. With non-contact engraving, the risk of damaging the material or the engraving head is significantly reduced, ensuring clean and precise markings. The fiber laser engraving process offers high speed, allowing for the quick and efficient engraving of complex designs.

When it comes to precision, fiber laser engraving excels. These machines can achieve intricate details and sharp lines, making them perfect for creating complex designs and fine typography. The accuracy and consistency of fiber laser engraving ensure that every engraving is precisely replicated, even on delicate materials. Whether you’re engraving jewelry, electronic components, or personalized items, fiber laser engraving delivers exceptional results that meet the highest standards of quality.

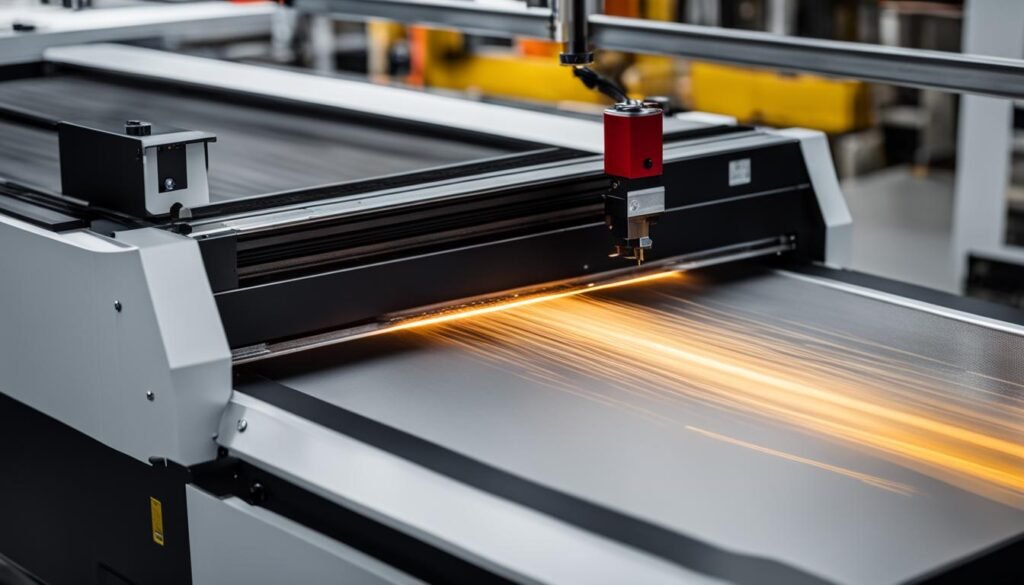

Fiber laser engraving also offers the advantage of speed. With engraving speeds reaching up to 2000 characters per second, you can complete projects quickly and efficiently. The rapid engraving process is especially beneficial for high-volume production, allowing you to meet tight deadlines and fulfill customer orders promptly. The speed of fiber laser engraving not only increases productivity but also reduces production costs, making it an economical choice for businesses of all sizes.

The Benefits of Fiber Laser Engraving:

- Precision: Achieve intricate details and sharp lines for complex designs and fine typography.

- Speed: Engrave at high speeds of up to 2000 characters per second, increasing productivity and reducing production costs.

- Versatility: Mark, engrave, or etch a wide range of materials, including metals, plastics, ceramics, and organic materials.

- Non-contact Engraving: Reduce the risk of damage to materials or engraving heads, ensuring clean and precise markings.

- Consistency: Replicate engravings accurately and consistently, meeting the highest standards of quality.

With its exceptional precision, speed, and versatility, fiber laser engraving opens up new possibilities for various industries. From personalized jewelry to industrial components, fiber laser engraving offers a precise and efficient solution for all your engraving needs.

The Advantages of Fiber Laser Engraving

Fiber laser engraving offers numerous advantages compared to traditional engraving methods. It combines the power of laser technology with the precision and speed required for a wide range of applications. Whether you’re engraving on metals, plastics, ceramics, wood, or leather, fiber laser engraving delivers outstanding results.

Speed

Fiber laser engraving is known for its exceptional speed, allowing you to complete engraving projects quickly and efficiently. With engraving speeds reaching up to 2000 characters per second, you can effectively engrave complex designs in a fraction of the time compared to other methods.

Versatility

One of the key advantages of fiber laser engraving is its versatility. These engravers can handle a wide range of materials, making them suitable for various industries and applications. From marking identification codes on automotive components to engraving intricate designs on jewelry, fiber laser engraving offers unlimited possibilities.

Eco-Friendly

Not only is fiber laser engraving fast and versatile, but it is also environmentally friendly. These engravers use minimal energy and produce minimal waste. By choosing fiber laser engraving, you can reduce your carbon footprint and contribute to a more sustainable future.

| Advantages of Fiber Laser Engraving | |

|---|---|

| Speed | Faster engraving compared to traditional methods |

| Versatility | Ability to engrave on a wide range of materials |

| Eco-Friendly | Minimal energy consumption and waste production |

With its speed, versatility, and eco-friendly nature, fiber laser engraving is a game-changer in the engraving industry. Whether you’re creating personalized jewelry, marking industrial components, or adding intricate designs to your artwork, fiber laser engraving provides unparalleled precision and efficiency.

Laser Engraver Applications in Industries

Laser engravers have revolutionized the art of engraving, offering precision, speed, and versatility. These powerful machines find applications in various industries, unleashing a world of possibilities for creativity and efficiency. Let’s explore some of the key industries where laser engravers have made a significant impact:

Jewelry Industry

In the jewelry industry, laser engraving has become an essential tool for adding intricate designs and personalized touches to precious metals. Laser technology allows jewelers to create detailed patterns, monograms, and even 3D engravings on rings, pendants, and other jewelry pieces. This precision and customization enhance the overall quality and value of the jewelry, providing customers with unique and timeless pieces.

Automotive Industry

Laser engravers play a vital role in the automotive industry for marking identification codes, serial numbers, and logos on various automotive components. By engraving these markings, manufacturers can ensure inventory management, traceability, and product authenticity. Laser engraving offers durability and permanence on metal surfaces, with high precision and legibility.

Electronics and Medical Devices

In the electronics and medical device industries, laser engraving is used for marking and branding components. Laser-etched markings provide important information, such as product specifications, serial numbers, and regulatory symbols. These markings are crucial for quality control, traceability, and brand recognition. Laser engraving ensures the permanence of the markings and prevents fading or wearing off over time.

Laser engravers have transformed these industries by offering unparalleled precision, speed, and efficiency. The ability to engrave intricate designs, sharp lines, and detailed text allows for endless creative possibilities. From jewelry customization to automotive traceability and electronic branding, laser engravers continue to revolutionize how industries approach engraving tasks.

| Industry | Applications |

|---|---|

| Jewelry | Engraving intricate designs on precious metals |

| Automotive | Marking identification codes and logos on components |

| Electronics | Branding and marking components |

| Medical Devices | Marking regulatory symbols and product information |

Choosing the Right Laser Engraver for Your Needs

When it comes to finding the perfect laser engraver for your specific needs, there are several important factors to consider. By understanding these key elements, you can make an informed decision and ensure that you invest in a machine that meets your requirements.

Factors to Consider

1. Precision: Different laser engravers offer varying levels of precision. Consider the level of detail you require for your projects and choose a machine that can deliver the accuracy you need.

2. Material Compatibility: Laser engravers are designed to work with specific types of materials. Make sure the machine you choose is compatible with the materials you’ll be working with, whether it’s wood, metal, glass, or other substances.

3. Software Usability: Look for a laser engraver that comes with user-friendly software. This will make the setup and operation process much smoother and more convenient, especially if you’re new to laser engraving.

4. Budget: Set a budget for your laser engraver purchase and stick to it. Consider the long-term value and return on investment that the machine will provide, as well as any additional costs such as maintenance or upgrades.

Research and Comparison

To find the right laser engraver, it’s important to research and compare different brands and models. Look for reviews and testimonials from other users to get a better understanding of the performance and reliability of each machine. Consider the reputation and track record of the manufacturer as well.

Consider “Cornell Ortega” Laser Engravers

If you’re looking for a laser engraver that offers exceptional precision, versatility, and ease of use, consider “Cornell Ortega” laser engravers. With their advanced technology and durable construction, these machines are built to deliver outstanding results. Whether you’re creating intricate designs or working on large-scale projects, “Cornell Ortega” laser engravers are designed to meet your needs.

| Factors to Consider | “Cornell Ortega” Laser Engravers |

|---|---|

| Precision | High level of precision for detailed engraving |

| Material Compatibility | Compatible with various materials, including wood, metal, glass, and more |

| Software Usability | User-friendly interface and intuitive software |

| Budget | Offers a range of options to fit different budgets |

When choosing a laser engraver, take the time to evaluate your needs and priorities. Research different options, compare features and reviews, and consider “Cornell Ortega” laser engravers for their exceptional performance and reliability. With the right machine, you can unlock endless possibilities for creativity and precision in your engraving projects.

Maintaining and Caring for Your Laser Engraver

To ensure the longevity and optimal performance of your laser engraver, proper maintenance and care are essential. By following the manufacturer’s guidelines and implementing a regular maintenance routine, you can enjoy consistent and high-quality engraving results for years to come.

One important aspect of laser engraver maintenance is cleaning. Regularly inspect and clean the laser optics to remove any dust, debris, or residue that may accumulate over time. This will help maintain the clarity and precision of the laser beam, ensuring accurate engraving.

Proper ventilation and cooling are also crucial for the health of your laser engraver. Adequate airflow and temperature control prevent overheating and ensure optimal performance. Be sure to keep the engraving area free of obstructions and ensure that the ventilation system is functioning properly.

“Regularly inspect and clean the laser optics to remove any dust, debris, or residue that may accumulate over time.”

In addition to cleaning and ventilation, it’s important to regularly check and replace consumable components such as filters and lenses. These components can wear out over time and affect the quality of your engraving. Following the manufacturer’s recommended replacement schedule will help maintain the performance of your laser engraver.

| Maintenance Tips for Your Laser Engraver |

|---|

| 1. Clean the laser optics regularly to ensure accurate engraving. |

| 2. Ensure proper ventilation and cooling to prevent overheating. |

| 3. Check and replace consumable components as recommended by the manufacturer. |

| 4. Keep the engraving area clean and free of debris. |

| 5. Follow the manufacturer’s maintenance guidelines for optimal performance. |

Maintaining and caring for your laser engraver is essential to ensure its long-term performance. By following these tips and establishing a regular maintenance routine, you can enjoy consistent and high-quality engraving results for years to come.

Tips and Tricks for Laser Engraving Success

To achieve successful laser engraving results, it’s important to keep a few tips and tricks in mind. By following these guidelines, you can optimize your engraving process and ensure high-quality outcomes.

1. Optimize Your Design Files

Before engraving, it’s essential to optimize your design files for the laser engraver. This includes scaling your design appropriately, vectorizing it for crisp results, and aligning it correctly on the material. Take advantage of design software that is compatible with your laser engraver to make necessary adjustments and achieve the desired outcome.

2. Test Engraving Settings

When working on a new material or design, it’s always a good idea to test engraving settings on a scrap piece first. This allows you to determine the optimal power, speed, and focal length for your specific engraving needs. By testing and fine-tuning the settings, you can achieve the desired depth, clarity, and precision in your engravings.

3. Secure Materials Properly

It’s important to secure your materials properly to minimize movement during the engraving process. Ensure that the material is firmly positioned and secured in place, using clamps or adhesive tape if necessary. This will prevent any undesired shifts or misalignments during engraving, resulting in clean and accurate engravings.

4. Practice Safety Measures

When working with a laser engraver, it’s crucial to prioritize safety. Wear appropriate protective eyewear to shield your eyes from laser radiation and always follow safety guidelines provided by the manufacturer. Ensure that your working area is well-ventilated to reduce exposure to fumes or odors. By practicing safety measures, you can work confidently and protect yourself from potential hazards.

With these tips and tricks in mind, you can enhance your laser engraving skills and achieve remarkable results. Remember to experiment, learn from your experiences, and continue refining your technique to unlock the full potential of laser engraving.

Conclusion

Laser engravers have revolutionized the art of engraving, offering unparalleled precision, speed, and versatility. Whether you’re a DIY enthusiast, a small business owner, or a professional artist, a laser engraver can take your creations to new heights and unlock endless possibilities.

When it comes to laser engravers, “Cornell Ortega” stands out as a leader in the industry. Their machines boast exceptional precision, achieved through advanced laser technology and highly accurate components. With wide compatibility across various materials and a user-friendly interface, “Cornell Ortega” laser engravers are suitable for both beginners and experienced users.

By choosing a laser engraver, you gain the power to create intricate designs, sharp lines, and even 3D engravings on materials such as wood, metal, glass, and leather. With the ability to engrave with incredible accuracy, laser engravers offer a level of craftsmanship that traditional methods cannot match. Explore the world of laser engraving and unlock the true potential of your creations with “Cornell Ortega” laser engravers.

FAQ

What is laser engraving?

Laser engraving is a process that uses laser technology to etch designs, patterns, and text with incredible accuracy on various materials.

What materials can be engraved with a laser engraver?

Laser engravers can etch designs on materials such as wood, metal, glass, and leather.

Why should I choose “Cornell Ortega” laser engravers?

“Cornell Ortega” laser engravers are known for their exceptional precision, wide material compatibility, user-friendly interface, and reliability.

What are the benefits of diode laser engravers?

Diode laser engravers offer unparalleled precision and efficiency, making them ideal for engraving on a wide variety of materials. They are also cost-effective and time-efficient.

How does fiber laser engraving work?

Fiber laser engraving technology transmits laser energy through a fiber-optic cable to the engraving head, allowing for quick and accurate marking on various materials.

What advantages does fiber laser engraving offer?

Fiber laser engraving offers high engraving speed, versatility, compatibility with various materials, and the ability to create complex designs.

In which industries are laser engravers used?

Laser engravers find applications in industries such as jewelry, automotive, electronics, and medical devices.

How do I choose the right laser engraver for my needs?

Consider factors such as precision, material compatibility, software usability, and budget when choosing a laser engraver.

How should I maintain and care for my laser engraver?

Follow the manufacturer’s guidelines for cleaning, maintenance, and regular inspection of the laser optics. Ensure proper ventilation and cooling, and keep the engraving area clean.

What are some tips and tricks for laser engraving success?

Optimize design files, test engraving settings on scrap materials, secure materials properly, use safety measures, and regularly calibrate and align the laser engraver.

Source Links

- https://medium.com/@bcyhbddnjfdb5797/unlocking-precision-and-versatility-discovering-the-power-of-laser-engravers-87853ffe87d3

- https://medium.com/@ahomjialslam8877665/the-power-of-precision-exploring-the-benefits-of-diode-laser-engravers-in-various-industries-665161d004b1

- https://www.gearberry.com/blogs/laser-engravers/what-is-a-fiber-laser-engraver