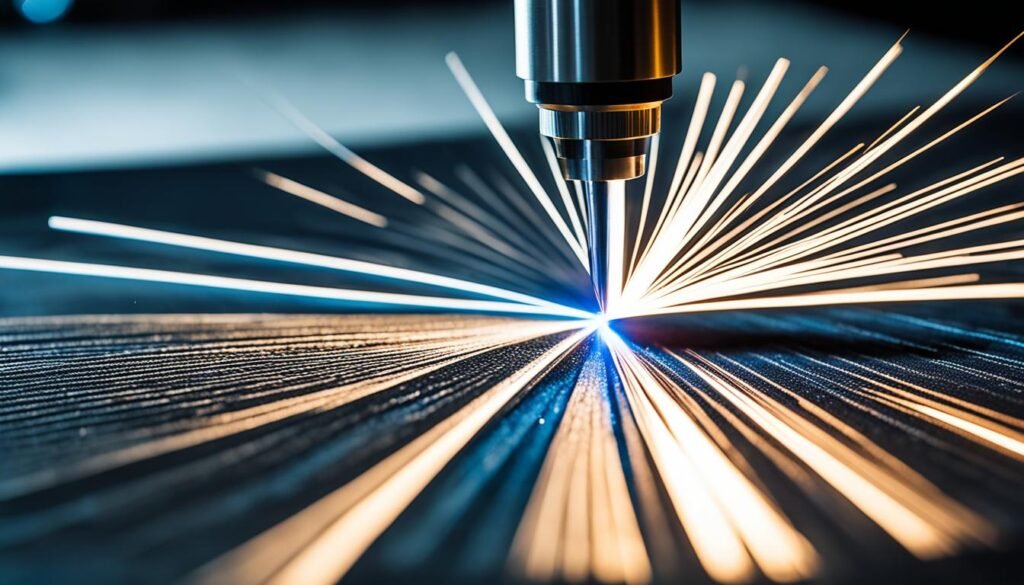

Looking for advanced laser solutions for precision cutting and engraving? Look no further than E Laser Solutions. With our cutting-edge technology and expertise in laser technology, we offer a wide range of solutions to meet all your needs.

As a leader in the industry, our laser engraving and cutting machines are renowned for their precision and efficiency. Whether you need to mark intricate designs on various materials or cut with utmost accuracy, our laser technology delivers exceptional results.

Our CO2 lasers are designed to provide precise and sharp engravings, ideal for applications in industries such as automotive, electronics, and more. With our laser engraving services, you can customize your products, enhance brand identity, and ensure traceability.

At E Laser Solutions, we understand the importance of speed and accuracy in industrial applications. Our laser engravers and cutters are built to handle high-volume production while maintaining impeccable quality.

Experience the power of laser technology with E Laser Solutions. Contact us today to learn more about our laser cutting machines, engravers, and other solutions. Let us help you achieve precision and efficiency like never before.

Contents

- 1 Laser Marking and Engraving

- 2 Micromachining

- 3 Welding

- 4 Selected Products

- 5 Applications

- 6 EVLASER Academy

- 7 EVLASER News

- 8 Conclusion

- 9 FAQ

- 9.1 What services does E Laser Solutions offer?

- 9.2 What is laser marking and engraving?

- 9.3 What is micromachining?

- 9.4 What is laser welding?

- 9.5 What are the selected products offered by E Laser Solutions?

- 9.6 In which industries does E Laser Solutions serve?

- 9.7 What does EVLASER Academy offer?

- 9.8 Where can I find updates on E Laser Solutions’ latest products and news?

Laser Marking and Engraving

Laser marking and engraving utilize the power of a laser light beam to modify the surface characteristics of different materials. This process involves techniques such as vaporizing, carbonizing, or oxidizing the surface to achieve precise and accurate results. E Laser Solutions specializes in cutting-edge laser marking and engraving technologies, catering to various industries.

Commonly used in automotive, electronics, and aerospace sectors, laser marking and engraving provide essential functions such as product identification, traceability, and customization. By utilizing the controlled energy of a laser light beam, E Laser Solutions can achieve high-quality surface modification, enhancing the material characteristics for specific applications.

“Laser marking and engraving allow us to achieve precise and accurate identification on a wide range of materials, ensuring traceability and customization for our clients.”

Through the precise control of the laser light beam, E Laser Solutions contributes to the creation of permanent marks on various materials, including metals, plastics, ceramics, and more. Laser marking and engraving are flexible and efficient methods for adding permanent logos, serial numbers, barcodes, or other markings to products.

E Laser Solutions ensures that the laser marking and engraving process is adaptable to different material characteristics, ensuring the desired outcomes. The laser’s ability to modify surface characteristics accurately provides excellent durability and readability, even in demanding environments.

| Advantages of Laser Marking and Engraving | Applications |

|---|---|

|

|

Micromachining

Micromachining is a precise fabrication process used to create miniature components for various applications. As the demand for miniaturization continues to rise, E Laser Solutions recognizes the importance of providing micromachining solutions. By leveraging high-precision techniques, they cater to industries requiring smaller, lighter, and thinner products.

E Laser Solutions offers tools and expertise for achieving exceptional results in micromachining. Their capabilities include creating perfect holes, micrometric patterns, and sharp cuts. This enables the production of intricate mechanical, optical, and electronic devices. Whether it’s crafting delicate mechanical components or manufacturing intricate optical devices, E Laser Solutions’ micromachining expertise delivers the required precision and accuracy.

“Micromachining allows us to meet the growing demand for miniaturization in various industries. We understand the importance of precise and accurate fabrication, especially for mechanical, optical, and electronic devices.”

In today’s fast-paced world, where technological advancements drive innovation, micromachining plays a vital role. The ability to create intricate and precise components is crucial for developing advanced mechanical hardware, optical sensors, and electronic devices. E Laser Solutions’ micromachining services streamline the manufacturing process, ensuring reliable and high-performance components.

Benefits of Micromachining

- Enables miniaturization of mechanical, optical, and electronic devices

- Produces intricate components with high precision and accuracy

- Offers versatility in creating various shapes, patterns, and cuts

- Ensures consistent quality and reliability

- Allows for efficient production processes

Through their micromachining capabilities, E Laser Solutions empowers industries to embrace miniaturization and develop cutting-edge products. The precise fabrication of miniature components paves the way for innovative advancements in mechanical, optical, and electronic devices.

Welding

Laser welding, also known as laser beam welding, is a fast and effective method of joining metal or plastic components. This advanced technique utilizes a focused laser beam to melt and fuse materials together, creating a strong and durable bond.

At E Laser Solutions, we offer top-of-the-line laser welding solutions for a wide range of applications. Whether you need to weld metal components for automotive manufacturing or join plastic components for electronics assembly, our laser welding technology provides the speed and precision you require.

One of the key advantages of laser welding is its ability to produce clean and precise welds. The focused laser beam allows for pinpoint accuracy, resulting in strong joints with minimal distortion. This makes laser welding a preferred method in industries such as automotive, aerospace, and manufacturing, where reliability and quality are paramount.

Furthermore, laser welding offers significant time and cost savings compared to traditional welding methods. The concentrated heat source and precise control ensure faster weld times and reduce the need for post-welding finishing processes. This boosts overall productivity and helps meet tight production schedules.

With our laser welding solutions, you can achieve consistent and reliable welds, even on intricate or delicate components. The non-contact nature of laser welding minimizes damage to surrounding materials, reducing the risk of warping or deformation.

To illustrate the benefits of laser welding, consider the following comparison:

| Traditional Welding | Laser Welding |

|---|---|

| Requires filler material | No filler material required |

| Prone to thermal distortion | Minimal thermal distortion |

| Slow welding speed | Fast welding speed |

| Difficult to weld small or complex components | High precision welds on small and complex components |

As shown in the table above, laser welding offers significant advantages over traditional welding methods. Its ability to create stronger and more precise welds, while minimizing distortion and enhancing productivity, makes it an ideal choice for a wide range of applications.

Explore our laser welding solutions at E Laser Solutions and experience the benefits of this fast and effective joining method.

Selected Products

E Laser Solutions offers a range of selected products designed to meet various industrial needs. Two standout products in their lineup are the Icon X and Titan Rotoweld, which offer exceptional performance and versatility.

The Icon X is a compact yet powerful platform that combines small dimensions with a large work area. This makes it an ideal choice for a wide range of applications. Notably, the Icon X can be used for laser cleaning, providing precise and efficient cleaning of semi-finished products. Whether it’s removing contaminants or preparing surfaces for further processing, the Icon X delivers exceptional results.

| Key Features of the Icon X |

|---|

| Versatile platform |

| Compact design |

| Large work area |

| Precision laser cleaning |

The Titan Rotoweld is another impressive product that offers high productivity capabilities for welding applications. This system is designed to meet different welding requirements, delivering reliable and efficient results. The Titan Rotoweld is available in a ROTOWELD version with a rotary table, further enhancing its versatility and productivity.

| Key Features of the Titan Rotoweld |

|---|

| High productivity capabilities |

| Versatile system |

| Designed for welding applications |

| Available in ROTOWELD version |

Applications

E Laser Solutions is dedicated to serving a wide range of industries with their innovative industrial solutions. Through their expertise in laser technology, they cater to the needs of various applications in the automotive, electronics, aerospace, and other industries, providing reliable and high-performance custom products.

Industrial Applications

With a deep understanding of the unique requirements of each industry, E Laser Solutions offers targeted solutions to meet the specific needs of industrial applications. Whether it is precision cutting, engraving, or micromachining, their solutions ensure optimal results and high-quality outcomes.

Automotive

The automotive industry relies on precise and efficient production methods to meet the demands of modern vehicle manufacturing. E Laser Solutions provides cutting-edge laser technology for automotive applications, offering solutions for precision cutting of automotive components, laser marking for part identification and traceability, and laser welding for seamless joining of metal components.

Electronics

In the fast-paced world of electronics manufacturing, accuracy and efficiency are crucial. E Laser Solutions understands the intricate nature of electronic components and offers laser solutions for micromachining, including creating perfect holes, micrometric patterns, and sharp cuts. Their high precision micromachining capabilities enable manufacturers to produce miniature components with exceptional precision and high-quality standards.

Aerospace

The aerospace industry demands stringent standards and requires components that are lightweight, durable, and precise. E Laser Solutions caters to aerospace applications with their advanced laser technology, providing solutions for precision cutting and micromachining of aerospace components. Their high precision micromachining techniques ensure the fabrication of miniature components that meet the exacting standards of the aerospace industry.

High Precision Micromachining

High precision micromachining plays a vital role in various industries, from medical devices to optical and electronic components. E Laser Solutions’ expertise in this field enables them to deliver accurate and reliable micromachining solutions. Their commitment to precision and quality ensures that customers receive custom products that meet the highest standards of performance.

| Industry | Applications |

|---|---|

| Automotive | Precision cutting, laser marking, laser welding |

| Electronics | Micromachining of electronic components |

| Aerospace | Precision cutting, micromachining of aerospace components |

EVLASER Academy

Expand your knowledge and expertise in laser technology with EVLASER Academy. Our academy offers valuable insights and resources on various aspects of laser technology, empowering you to master the art of precision cutting and engraving.

With our comprehensive collection of resources, you can explore the intricacies of CO2 laser sources, understand their different types, variations, and applications. Dive deep into the world of laser micro drilling and discover how this technique enables intricate and precise hole drilling in various materials.

“EVLASER Academy offers a wealth of knowledge on laser engraving and marking. Discover the art of laser engraving on leather and unleash your creativity on this unique material. Learn the techniques and best practices for producing stunning results with laser engraving on wood.”

Our academy serves as a platform to enhance your understanding of laser technology and its diverse applications. We provide informative articles, tutorials, and case studies that cater to beginners as well as experienced professionals in the field.

At EVLASER Academy, we believe that continuous learning is essential for staying ahead in the ever-evolving laser industry. Join us on this educational journey and unlock the full potential of laser technology.

Why Choose EVLASER Academy?

- Comprehensive resources on CO2 laser sources

- In-depth insights into laser micro drilling

- Techniques and best practices for laser engraving on leather

- Creative possibilities with laser engraving on wood

- Informative articles, tutorials, and case studies

EVLASER News

Stay updated with the latest news from EVLASER, where we share exciting developments, innovative collaborations, and cutting-edge products in laser technology.

At EVLASER, we actively participate in industry events and exhibitions to showcase our laser solutions and advancements in laser material processing. These platforms provide us with the opportunity to connect with industry professionals, potential customers, and like-minded individuals.

We are proud to be exhibiting at MECSPE Bologna, one of the most prominent trade fairs for the manufacturing industry in Italy. This event brings together experts and professionals from various sectors, providing a unique platform for knowledge exchange and networking.

In addition, we are excited to present our latest innovations at LASYS Stuttgart, an internationally renowned trade fair dedicated to laser material processing. This event attracts a global audience, offering insights into the latest advancements and trends in laser technology.

Commercial partnerships are an integral part of our business strategy. We welcome collaborations with individuals and companies that share our vision and values. If you are interested in exploring a commercial partnership with us, we invite you to reach out and further discuss the possibilities.

Subscribe to our news section to receive updates on our latest products, new developments, and collaborations in the field of laser technology. Stay informed about the advancements and applications of laser material processing that are shaping various industries.

Conclusion

In conclusion, E Laser Solutions is your trusted provider of cutting-edge laser solutions for precision cutting and engraving. With their expertise in laser technology and commitment to delivering high-quality results, they have established themselves as a leader in the industry.

Whether you need laser marking, micromachining, or welding services, E Laser Solutions has got you covered. Their industrial solutions offer unparalleled precision, ensuring accurate and efficient outcomes for your projects. From automotive to aerospace, they cater to a wide range of industries, delivering custom products that meet the highest standards.

One of the highlights of E Laser Solutions is their selection of versatile products, including the Icon X and Titan Rotoweld. These innovative machines are designed to meet diverse industry needs, offering exceptional accuracy and speed. Whether it’s precision cutting or engraving, these products provide the reliability and efficiency you require.

With E Laser Solutions, you can trust that your precision cutting and engraving needs will be met with utmost accuracy and speed. Their commitment to excellence and their cutting-edge laser solutions make them the go-to choice for businesses seeking top-notch results. Experience the difference of E Laser Solutions and elevate your precision applications to a whole new level.

FAQ

What services does E Laser Solutions offer?

E Laser Solutions offers a range of industrial solutions including laser marking and engraving, micromachining, and welding.

What is laser marking and engraving?

Laser marking and engraving involve using a laser light beam to modify the surface characteristics of the material for product identification, traceability, and customization.

What is micromachining?

Micromachining is the precise fabrication of miniature components for various applications, including mechanical devices, optical devices, and electronic devices.

What is laser welding?

Laser welding, or laser beam welding, is a fast and effective method of joining metal or plastic components.

What are the selected products offered by E Laser Solutions?

E Laser Solutions offers selected products such as the Icon X and Titan Rotoweld, which are versatile and designed to meet various industry needs.

In which industries does E Laser Solutions serve?

E Laser Solutions serves industries such as automotive, electronics, aerospace, and more with their high precision micromachining solutions.

What does EVLASER Academy offer?

EVLASER Academy provides valuable insights and resources on CO2 laser sources, laser micro drilling, laser engraving on various materials like leather and wood.

Where can I find updates on E Laser Solutions’ latest products and news?

You can find updates on E Laser Solutions’ latest products, innovations, and collaborations in their news section on their website.