Contents

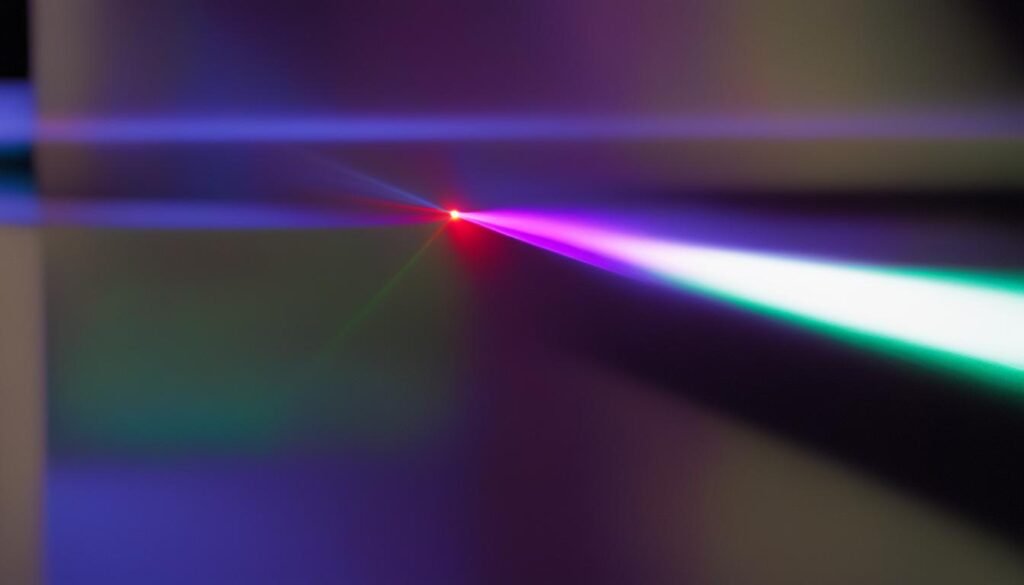

Laser technology has revolutionized material processing in various industries, including medical device manufacturing. The ability to tailor laser parameters such as wavelength, power levels, and pulse durations allows engineers to overcome specific processing challenges effectively.

When it comes to laser material processing, understanding the interaction between lasers, lenses, and different materials is crucial. The choice of laser lens and wavelength can have a significant impact on the efficiency and quality of material processing.

The absorption of laser light by materials depends on the laser wavelength and the properties of the material. Laser cutting, welding, drilling, and marking are common applications in medical device manufacturing, and optimizing laser lens and wavelength can enhance the precision and effectiveness of these processes.

Key Takeaways:

- The choice of laser lens and wavelength has a significant impact on material processing.

- Understanding the laser-material interaction is crucial for optimizing laser processing systems.

- Considerations need to be made for safety, lens performance, and the specific material properties.

- Laser wavelength affects material absorption, cutting efficiency, and overall processing results.

- Engineers must have a good understanding of laser technology and its parameters to make informed decisions.

Laser-Material Interaction

When it comes to laser processing, understanding the interaction between the laser beam and the material is crucial. This interaction plays a significant role in determining the outcome of the material processing. When a laser beam interacts with a material, the energy is distributed through reflection, absorption, and transmission. The absorbed energy causes the temperature of the material to rise, leading to melting and potential evaporation.

The rate at which the material temperature rises depends on the balance between energy absorption and dissipation. Two key factors that influence this process are the optical absorption length and the thermal diffusion length. The optical absorption length indicates how far the laser light penetrates into the material before being absorbed, while the thermal diffusion length refers to the distance over which the heat spreads within the material.

The choice of laser wavelength and pulse width is critical in achieving the desired material processing effect. Different materials have unique absorption characteristics, and the laser wavelength needs to be optimized accordingly. By understanding the laser-material interaction, engineers can tailor the laser drilling parameters to achieve precise results. However, it is essential to consider the potential hazards of laser radiation, particularly retinal hazards, and implement appropriate safety measures.

Laser-Material Interaction Factors:

- Laser absorption

- Thermal diffusion length

- Pulse width

- Material temperature rise

- Laser drilling parameters

- Retinal hazards

| Factor | Description |

|---|---|

| Laser absorption | The amount of energy absorbed by the material |

| Thermal diffusion length | The distance over which the heat spreads within the material |

| Pulse width | The duration of the laser pulse |

| Material temperature rise | The increase in temperature caused by the absorbed energy |

| Laser drilling parameters | The specific settings used for laser drilling |

| Retinal hazards | The potential harm caused by laser radiation to the eyes |

Laser Wavelength and Material Processing Applications

When it comes to material processing using lasers, the choice of laser wavelength plays a crucial role in achieving the desired outcomes. Different wavelengths have different effects on material processing, and engineers must consider various factors when selecting the optimal wavelength for a particular application.

One important consideration is monochromatic illumination, which is commonly used to improve the performance of imaging systems by eliminating chromatic aberrations. Shorter wavelengths allow for better utilization of sensor pixels and provide higher resolution. However, it’s important to note that the performance of lenses may be limited at shorter wavelengths due to the characteristics of the glass materials used.

In order to ensure optimal performance, it is essential to evaluate the capabilities of the lens at different wavelengths. This evaluation should consider factors such as lens focal length, lens material properties, and lens design. By understanding the performance limitations of the lens at different wavelengths, engineers can make informed decisions and select the most suitable laser wavelength for their material processing application.

Lens Performance Comparison

| Wavelength (nm) | Lens A | Lens B | Lens C |

|---|---|---|---|

| 532 | Excellent | Good | Fair |

| 1064 | Fair | Excellent | Good |

| 1550 | Fair | Fair | Excellent |

In the table above, we compare the performance of three lenses (Lens A, Lens B, and Lens C) at different wavelengths (532nm, 1064nm, and 1550nm). The performance is rated as Excellent, Good, or Fair based on factors such as focusing capabilities, beam quality, and energy efficiency. The table provides a clear overview of how lens performance varies with different laser wavelengths, helping engineers make informed decisions when selecting the most suitable lens for their material processing application.

Conclusion

The choice of laser lens and wavelength plays a vital role in material processing. Understanding the interaction between lasers and materials, including their absorption characteristics and thermal diffusion length, allows engineers to optimize laser processing systems. By carefully selecting the appropriate wavelength, engineers can achieve precise and high-quality results in material processing.

When choosing the laser lens and wavelength, considerations need to be made for safety, lens performance, and the potential impact on the material. It is crucial to evaluate the specific material and processing requirements to determine the optimal wavelength. This ensures that the laser can effectively interact with the material, whether it is for cutting, welding, drilling, or marking purposes.

By combining a deep understanding of laser-material interaction with careful consideration of safety measures, engineers can design laser processing systems that deliver optimal results. With the right laser lens and wavelength, manufacturers can achieve efficient and accurate material processing, enabling the production of high-quality medical devices and other precision products.