Contents

- 1 Terminology and History of Excimer Laser Development

- 2 Construction and Operation of Excimer Lasers

- 3 Wavelength Determination of Excimer Lasers

- 4 Pulse Repetition Rate of Excimer Lasers

- 5 Photolithography Applications of Excimer Lasers

- 6 Fusion Applications of Excimer Lasers

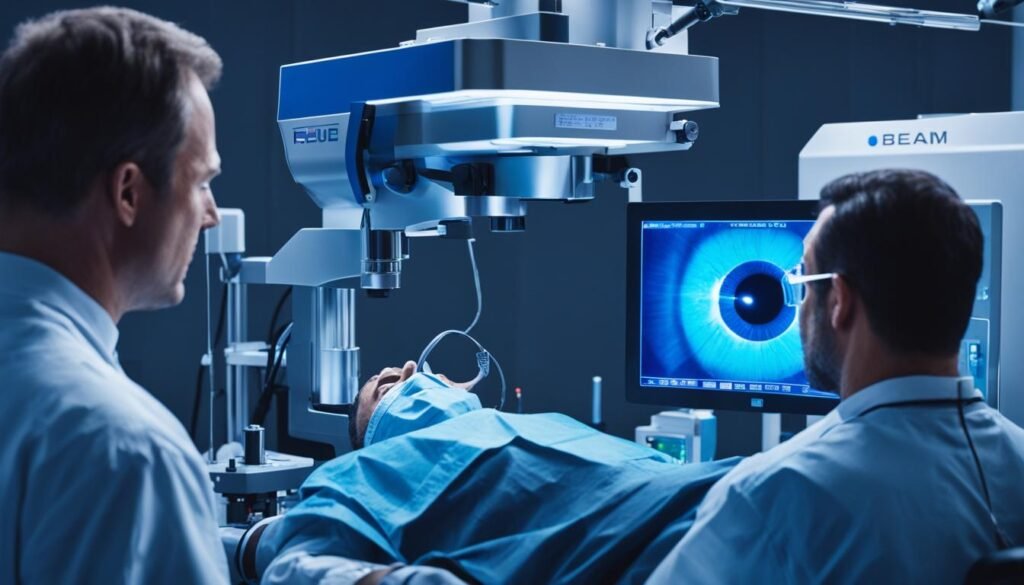

- 7 Medical Applications of Excimer Lasers

- 8 Other Applications of Excimer Lasers

- 9 The Future of Excimer Laser Technology

- 10 Conclusion

- 11 FAQ

- 11.1 What is an excimer laser?

- 11.2 How does an excimer laser work?

- 11.3 What are the different wavelengths produced by excimer lasers?

- 11.4 What are the applications of excimer lasers in medicine?

- 11.5 What are the applications of excimer lasers in manufacturing?

- 11.6 How are excimer lasers used in fusion research?

- 11.7 How are excimer lasers used in corneal refractive surgery?

- 11.8 What other applications do excimer lasers have?

- 11.9 What is the future of excimer laser technology?

- 11.10 How has excimer laser technology impacted various industries?

- 11.11 Can excimer lasers produce different pulse repetition rates?

- 12 Source Links

An excimer laser is a highly advanced and versatile medical device that utilizes ultraviolet laser technology in various applications. From eye surgery and skin resurfacing to therapy and treatment, excimer lasers have revolutionized the field of precision laser medicine.

Key Takeaways:

- Excimer lasers are a form of ultraviolet lasers used in medical procedures.

- They are widely used in eye surgery, skin resurfacing, and therapy.

- Excimer lasers create an energized state called an excimer or exciplex to emit laser light.

- The wavelengths of excimer lasers vary depending on the gases used.

- Excimer laser technology is advancing in various fields, offering new possibilities and applications.

Terminology and History of Excimer Laser Development

The development of excimer lasers, also known as exciplex lasers, has a fascinating history rooted in the exploration of noble gas halides. The term “excimer” is derived from “excited dimer,” while “exciplex” refers to an “excited complex.” These lasers have made significant contributions to various fields and owe their advancements to the pioneering work of several researchers and institutions.

In the 1960s and 1970s, researchers such as Fritz Houtermans, Nikolai Basov, V.A. Danilychev, Yu.M. Popov, and Mani Lal Bhaumik played pivotal roles in the development of excimer lasers. Their contributions paved the way for breakthroughs in excimer laser technology.

High-pressure xenon gas and noble gas halides, specifically xenon with bromine (XeBr) and xenon with chlorine (XeCl), were significant advancements in excimer laser technology. These developments allowed for the creation of excimer lasers that harnessed ultraviolet light emission.

Several esteemed research laboratories, including Avco Everett Research Laboratory, Sandia Laboratories, Naval Research Laboratory, and Los Alamos National Laboratory, played instrumental roles in the early stages of noble gas halide excimer laser development. Their collaborative efforts and groundbreaking research laid the foundation for the future applications of these powerful lasers.

Construction and Operation of Excimer Lasers

An excimer laser is a sophisticated device that operates based on the principles of laser action and population inversion. It consists of several key components, including a noble gas and a reactive gas, which work together to generate a precise and intense beam of ultraviolet light.

Excimer lasers utilize a combination of a noble gas, such as argon, krypton, or xenon, and a reactive gas like fluorine or chlorine. These gases are chosen for their specific properties and ability to form excimers or exciplexes, which are the active species responsible for the laser action.

How Excimer Lasers Work

When electrical stimulation is applied to the gas mixture inside the laser cavity, the noble gas atoms or molecules become excited. At the same time, the reactive gas molecules are also excited. Under high pressure, these excited gases come into close proximity, allowing them to form temporary excimers or exciplexes.

Excimer (exciplex) molecules are characterized by a bound (associative) excited state and a repulsive (dissociative) ground state.

The excimer molecules exist only in an energized state and are highly unstable. As a result, they quickly release their excess energy in the form of ultraviolet light in the range of 126 nm to 351 nm, depending on the specific gas combination and its energy levels.

Laser action occurs when the excited excimer molecules undergo spontaneous or stimulated emission, releasing photons of specific wavelengths. This emission process occurs due to population inversion within the molecules.

Population inversion is a state where more excimers are in their excited state rather than in their ground state, and it is essential for the amplification of light in a laser system.

Excimer lasers, such as those using xenon or krypton, have the unique capability to form these excimers or exciplexes, even though these noble gases are typically inert and do not readily form chemical compounds. The excited states of the noble gases allow them to temporarily bind with themselves or halogens like fluorine and chlorine, resulting in the formation of the active species responsible for laser action.

Components and Construction

The construction of an excimer laser involves several critical components, including:

- Gas reservoirs: These chambers contain the noble gas, such as xenon or krypton, and the reactive gas, like fluorine or chlorine. The gases are carefully mixed in specific ratios to achieve the desired excimer formation.

- Electrical discharge system: This system provides the necessary electrical energy to excite the gas mixture and initiate the laser action. It typically consists of high-voltage power supplies, electrodes, and discharge chambers.

- Optical resonator: The optical resonator is responsible for amplifying and directing the laser beam. It includes mirrors or lenses to reflect and focus the emitted light, ensuring a high-energy and well-collimated beam.

- Control system: The control system manages the electrical power, gas flow rates, and other operational parameters to optimize the laser performance and ensure safe and consistent operation.

Applications of Excimer Lasers

Excimer lasers have proven to be incredibly versatile and find applications in various fields, including:

- Corneal refractive surgery: Excimer lasers are widely used for precise and predictable vision correction in procedures such as LASIK and PRK. The laser beam is used to reshape the cornea, correcting refractive errors.

- Micromachining: Excimer lasers are utilized in precision cutting, drilling, and shaping of materials, especially in the electronics industry. They can create intricate patterns with high accuracy.

- Photolithography: Excimer lasers play a crucial role in the production of microelectronic devices, enabling the lithographic process necessary for manufacturing semiconductor chips.

- Scientific research: Excimer lasers are used in various research fields, including fusion experiments, spectroscopy, and material studies.

The unique characteristics of excimer lasers, such as their ultraviolet wavelength range, precise control, and intense beam, make them indispensable tools in numerous scientific, industrial, and medical applications.

| Application | Description |

|---|---|

| Corneal refractive surgery | Precise and predictable vision correction for refractive errors |

| Micromachining | Precision cutting, drilling, and shaping of materials |

| Photolithography | Manufacturing of microelectronic devices |

| Scientific research | Used in various research fields, including fusion experiments and materials studies |

Wavelength Determination of Excimer Lasers

The wavelength of an excimer laser is determined by the specific combination of gases used. Most excimer lasers operate within the ultraviolet range of the electromagnetic spectrum. Noble gas halides, such as argon (Ar), krypton (Kr), and xenon (Xe), are commonly used in excimer lasers to produce different wavelengths.

- Ar2*: 126 nm

- Kr2*: 146 nm

- F2*: 157 nm

- Xe2*: 172 & 175 nm

- ArF: 193 nm

- KrCl: 222 nm

- KrF: 248 nm

- XeBr: 282 nm

- XeCl: 308 nm

- XeF: 351 nm

The emission of laser light in the ultraviolet range allows excimer lasers to be used in various applications, including microelectronic manufacturing, eye surgery, and micromachining.

Pulse Repetition Rate of Excimer Lasers

Excimer lasers, renowned for their versatility and precision, operate at varying pulse repetition rates, depending on the pumping mechanism. Electron-beam pumped excimer lasers deliver high-energy pulses but exhibit longer time intervals between each pulse. On the other hand, discharge-pumped excimer lasers emit a continuous stream of pulses at higher repetition rates, generally around 100 Hz.

An example of an advanced system utilizing excimer lasers is the Electra system. Primarily designed for inertial fusion studies, the Electra system can generate a burst of 10 pulses, each measuring 500 J, over a span of 10 seconds.

Industrial-grade excimer lasers, such as XeCl lasers, are specifically engineered for high repetition rates, ensuring sustained energy per pulse. For instance, XMR, Inc. has successfully developed XeCl lasers capable of delivering a steady energy of 1 J per pulse, operating at a remarkable repetition rate of 300 pulses per second.

“The ability of excimer lasers to seamlessly combine high energy per pulse and rapid repetition rates makes them invaluable in industrial applications.”

| Excimer Laser Type | Energy per Pulse | Repetition Rate |

|---|---|---|

| Electron-beam Pumped | Varies, high single-energy pulses | Long time intervals |

| Discharge-pumped | Sustained energy per pulse | Higher repetition rates (around 100 Hz) |

| Industrial-grade (XeCl) | 1 J per pulse | 300 pulses per second |

In summary, the pulse repetition rate of excimer lasers depends on the specific pumping mechanism employed. Whether it is the controlled bursts of the Electra system or the sustained energy output of industrial-grade XeCl lasers, excimer lasers continue to push the boundaries of laser technology with their exceptional performance.

Photolithography Applications of Excimer Lasers

Excimer lasers have significantly contributed to the manufacturing of microelectronic devices through the process of photolithography. In the past, mercury-xenon lamps were used for photolithography; however, the industry demanded higher resolution and increased throughput. The introduction of excimer lasers, especially the KrF (krypton fluoride) and ArF (argon fluoride) lasers operating in the deep ultraviolet range, facilitated higher resolution and faster chip production.

Excimer laser lithography plays a critical role in advancing semiconductor chip technology and upholding Moore’s law. These lasers enable the production of smaller features on semiconductor chips, allowing for more components and increased functionality. With the constant drive for miniaturization and improved performance, excimer lasers have been vital in pushing the boundaries of microelectronics.

Recently, extreme ultraviolet lithography (EUV) has gained traction as a potential replacement for excimer laser lithography. EUV lithography utilizes even shorter wavelengths to achieve higher resolution and greater accuracy in the production of microelectronic devices.

Excimer lasers have revolutionized the semiconductor industry, enabling the fabrication of increasingly complex microelectronic devices with higher precision and efficiency.

Resolution and Moore’s Law

One of the key factors driving the adoption of excimer laser lithography is the constant pursuit of higher resolution in semiconductor chip manufacturing. The semiconductor industry follows Moore’s law, which states that the number of transistors on a chip doubles approximately every two years. Achieving higher resolution is essential to accommodate the increasing number of transistors on a chip and maintain the pace set by Moore’s law.

Excimer lasers with deep ultraviolet wavelengths, such as KrF and ArF, have played a pivotal role in keeping up with the demands of Moore’s law. These lasers have the capability to produce smaller features on semiconductor chips, pushing the boundaries of what is possible in microelectronic device fabrication.

Benefits of Excimer Laser Lithography

- High-resolution capabilities: Excimer lasers operating in the deep ultraviolet range allow for the production of smaller features on semiconductor chips, enabling the creation of more advanced microelectronic devices.

- Increased throughput: Excimer laser lithography enables faster chip production, meeting the industry’s demand for higher productivity and shorter manufacturing cycles.

- Precision and accuracy: The precise control of excimer lasers ensures accurate replication of intricate patterns, resulting in highly reliable microelectronic devices.

| Excimer Laser Type | Wavelength | Applications |

|---|---|---|

| KrF | 248 nm | Submicron semiconductor chip manufacturing |

| ArF | 193 nm | Advanced semiconductor lithography and extreme ultraviolet lithography (EUV) research |

These benefits have made excimer laser lithography an integral part of semiconductor chip manufacturing, contributing to the development of smaller, faster, and more powerful microelectronic devices.

Fusion Applications of Excimer Lasers

Excimer lasers have found valuable applications in the field of fusion research, specifically in inertial confinement fusion. A notable development in this area is the use of Krypton fluoride (KrF) and Argon fluoride (ArF) lasers by the Naval Research Laboratory. These lasers have been instrumental in testing various approaches to achieve fusion reactions.

The KrF and ArF lasers, such as the Electra system and the Nike laser, offer a gas-based alternative to solid-state laser systems like the National Ignition Facility and the Omega Laser. The ability of excimer lasers to produce high-energy, rapid pulses makes them well-suited for studying and achieving inertial fusion.

“The use of excimer lasers in fusion research has opened up new possibilities for achieving controlled fusion reactions. These lasers have proven to be a powerful tool in the pursuit of clean and efficient energy.”

The Electra system, powered by an excimer laser, demonstrates the potential of this technology in fusion research. It has been used extensively for studying and understanding the dynamics of inertial confinement fusion. The Nike laser, another remarkable application of excimer laser technology, focuses on achieving fusion through controlled compression of the fusion target.

Advantages of Excimer Lasers in Fusion Research

Excimer lasers offer several advantages in the field of fusion research:

- High-energy, rapid pulses: Excimer lasers are capable of delivering intense bursts of energy in short durations, enabling the generation of high temperatures and pressures needed for fusion reactions.

- Gas-based operation: The use of noble gas halides, such as Krypton fluoride and Argon fluoride, provides a versatile and controllable medium for achieving fusion reactions.

- Precision and control: Excimer lasers allow scientists to precisely control the energy and timing of each pulse, facilitating accurate experimentation and analysis.

- Research insight: By studying the behavior of excimer lasers in fusion environments, researchers gain valuable insights into the complex physics and dynamics of fusion reactions.

With ongoing advancements in excimer laser technology, fusion research is poised to make significant strides in achieving sustainable and efficient fusion reactions.

The Role of Excimer Lasers in Advancing Fusion Research

| Excimer Laser System | Application |

|---|---|

| Electra | Inertial confinement fusion studies |

| Nike | Controlled compression of fusion targets |

Medical Applications of Excimer Lasers

Excimer lasers have revolutionized the field of medical procedures, particularly in corneal refractive surgery. These advanced lasers offer precise and predictable vision correction for conditions such as nearsightedness, farsightedness, and astigmatism. The use of excimer lasers has significantly improved the effectiveness and safety of corneal refractive surgeries.

The key advantage of excimer lasers in corneal refractive surgery lies in their precision and predictability. The high level of accuracy and control of the laser allows for tissue removal in extremely small increments, resulting in precise ablation of the corneal tissue. Each pulse of the excimer laser removes only about 0.25 microns of corneal tissue, ensuring minimal disruption to the surrounding areas.

The cool light beam emitted by the excimer laser is crucial for the success of corneal refractive surgeries. The laser breaks the molecular bonds of the corneal tissue, allowing for precise tissue ablation without causing damage to the surrounding tissues. This targeted approach ensures the integrity and safety of the eye during the surgical procedure.

Excimer lasers have transformed corneal refractive surgery, enabling precise and predictable vision correction with minimal risks. The high level of control and accuracy offered by these lasers has revolutionized the field, providing patients with improved visual outcomes and a higher quality of life.

Furthermore, excimer lasers have significantly improved the predictability of corneal refractive surgeries. The ability to remove tissue in precise increments allows for a more reliable and predictable outcome, ensuring that patients achieve their desired results. This predictability has increased patient satisfaction and confidence in the effectiveness of corneal refractive surgeries.

The exceptional precision of excimer lasers in corneal refractive surgery has also led to advancements in minimizing tissue removal. By targeting only the specific areas requiring correction, excimer lasers minimize unnecessary tissue removal, preserving the structural integrity of the cornea and promoting faster healing and recovery.

Excimer lasers have transformed corneal refractive surgery, enabling precise and predictable vision correction with minimal risks. The high level of control and accuracy offered by these lasers has revolutionized the field, providing patients with improved visual outcomes and a higher quality of life.

Overall, excimer lasers have brought about a paradigm shift in the field of corneal refractive surgery. Their precision, predictability, and ability to safely remove tissue make them indispensable tools for ophthalmologists and refractive surgeons. With their exceptional safety profile and effectiveness, excimer lasers have improved the lives of countless individuals by offering a reliable and efficient solution for vision correction.

Other Applications of Excimer Lasers

Excimer lasers offer a wide range of applications beyond the realms of microelectronic device manufacturing and medical procedures. Their precision and versatility make them invaluable for various tasks, such as micromachining, via drilling, glass processing, biophotonics, and the utilization of femtosecond laser pulses.

Micromachining

In the field of micromachining, excimer lasers are utilized for cutting, drilling, and shaping materials with exceptional precision. Their focused laser beams enable the creation of intricate structures in tiny components, making them ideal for industries that require high-quality micro-scale manufacturing.

Via Drilling

Excimer lasers are effective tools for via drilling in circuit boards. By emitting precise laser beams, they can create small holes in the circuitry for electrical connections, ensuring efficient communication between different layers of the board.

Glass Processing

Another important application of excimer lasers is in glass processing. With their high-energy ultraviolet laser pulses, excimer lasers can be used to etch, engrave, and shape glass materials, providing opportunities for artistic designs and intricate patterns. This application finds usage in the production of glassware, precision optics, and display technologies.

Biophotonics

Excimer lasers have made significant contributions to the field of biophotonics. Specifically, in F2-laser microfabrication, excimer lasers enable the creation of small structures used in various photonics and biophotonics applications. This includes the fabrication of microfluidic channels, photonic sensors, and optofluidic devices, opening up new possibilities in the study and application of light in biology and medicine.

Femtosecond Laser Pulses

The use of femtosecond excimer laser pulses allows for nano-structuring with exceptional precision. By emitting ultrashort laser pulses in the femtosecond range, excimer lasers enable the manipulation of materials at the atomic and molecular levels. This technology finds application in fields such as nanotechnology, materials science, and advanced manufacturing processes.

Excimer lasers play a vital role in various industrial and scientific applications, ranging from micromachining and glass processing to biophotonics and the use of femtosecond laser pulses. The versatility and precision of excimer lasers make them indispensable tools in pushing the boundaries of technology and innovation.

The Future of Excimer Laser Technology

Excimer laser technology continues to advance with ongoing research and development in various fields. The future of excimer lasers holds exciting possibilities for improving performance, expanding applications, and exploring new frontiers in nanotechnology, materials science, and biomedicine. With new laser designs and technological innovations on the horizon, excimer lasers are set to become even more efficient, versatile, and adaptable to changing needs.

One of the future trends in excimer laser technology is the development of more sophisticated laser designs. Researchers are exploring ways to enhance the output power, beam quality, and pulse characteristics of excimer lasers. By improving laser performance, these advancements will enable more precise and efficient laser-based processes in various applications.

Advancements in excimer laser technology will also lead to the expansion of its applications. Excimer lasers have already found success in fields such as microelectronic manufacturing, medical procedures, and micromachining. In the future, excimer lasers may also play a significant role in emerging fields such as nanotechnology, where their precise and controlled energy delivery can enable the fabrication of intricate structures on a nanoscale.

Advancements in Excimer Laser Applications

Excimer lasers have the potential to revolutionize fields like materials science and biomedicine. In materials science, excimer lasers can be used for precise ablation, etching, and surface modification of various materials, leading to advancements in areas such as microelectronics, photonics, and energy storage.

In biomedicine, excimer lasers show promise in areas such as tissue engineering and regenerative medicine. The ability of excimer lasers to precisely remove tissue without causing thermal damage makes them suitable for procedures like corneal refractive surgery. In the future, excimer lasers may find applications in new therapeutic techniques and targeted drug delivery systems, enhancing the field of biomedicine.

Exploring New Frontiers

The future of excimer laser technology involves the exploration of new frontiers, pushing the limits of what is possible. With ongoing research, scientists are constantly uncovering new applications and possibilities for excimer lasers.

“Excimer lasers have the potential to revolutionize fields like materials science and biomedicine.”

For example, researchers are investigating the use of excimer lasers in next-generation lithography techniques, such as extreme ultraviolet lithography (EUV). EUV uses even shorter wavelengths of light to achieve higher resolution in microchip manufacturing. Excimer lasers may play a crucial role in enabling the transition from current photolithography techniques to EUV, further advancing the field of microelectronics.

Furthermore, excimer lasers may find applications in novel areas such as quantum technology and advanced imaging techniques. Their unique properties, precise control over energy delivery, and ability to operate in the ultraviolet range make them promising candidates for these cutting-edge fields.

The future of excimer laser technology is filled with possibilities, propelled by ongoing advancements and research. As the technology continues to evolve, we can expect excimer lasers to play an increasingly significant role in various industries, pushing the boundaries of what is possible and driving innovation forward.

Conclusion

Excimer laser technology has revolutionized various industries, showcasing its versatility and precision in applications such as microelectronic manufacturing, fusion research, medical procedures, and micromachining. Its ability to emit ultraviolet light and its precise control over tissue removal have made it an indispensable tool.

As technology advances and research progresses, the future of excimer lasers holds significant promise. Further developments in excimer laser technology are expected to lead to breakthroughs in materials science, biophotonics, and nanotechnology. These advancements will unlock new applications and enhance the precision and versatility of this cutting-edge technology.

Excimer lasers will play a vital role in the continual advancement of microelectronic devices, further pushing the boundaries of chip manufacturing. Additionally, the use of excimer lasers in fusion research, especially inertial confinement fusion, will contribute to our understanding of energy production and fusion processes.

Excimer laser technology will also continue to revolutionize medical procedures, particularly in corneal refractive surgery, where its precision and predictability have transformed the field. Moreover, excimer lasers will find increasing applications in micromachining, via drilling, glass processing, and biophotonics, enabling high-precision operations in diverse industries.

FAQ

What is an excimer laser?

An excimer laser is a form of ultraviolet laser used in the production of microelectronic devices, eye surgery, and micromachining.

How does an excimer laser work?

Excimer lasers work by creating a pseudo-molecule called an excimer or exciplex, which can only exist in an energized state and emits laser light in the ultraviolet range.

What are the different wavelengths produced by excimer lasers?

Excimer lasers produce different wavelengths depending on the gases used, ranging from 126 nm to 351 nm.

What are the applications of excimer lasers in medicine?

Excimer lasers are used in eye surgery, skin resurfacing, and therapy, offering precise and effective treatments.

What are the applications of excimer lasers in manufacturing?

Excimer lasers are widely used in the manufacturing of microelectronic devices through the process of photolithography.

How are excimer lasers used in fusion research?

Excimer lasers, such as Krypton fluoride and Argon fluoride lasers, have been utilized in the field of inertial confinement fusion for testing approaches to achieving fusion.

How are excimer lasers used in corneal refractive surgery?

Excimer lasers offer precise and predictable vision correction for nearsightedness, farsightedness, and astigmatism, improving the safety and effectiveness of corneal refractive surgeries.

What other applications do excimer lasers have?

Excimer lasers are used in micromachining processes, via drilling in circuit boards, and for processing materials like glass and polymers. They also play a role in biophotonics and femtosecond laser pulses for nano-structuring.

What is the future of excimer laser technology?

Excimer laser technology continues to advance, with ongoing research and development in various fields. The future holds improvements in performance and applications, exploring new possibilities in nanotechnology, materials science, and biomedicine.

How has excimer laser technology impacted various industries?

Excimer lasers have revolutionized microelectronic manufacturing, medical procedures, and research, offering precision, versatility, and ultraviolet light emissions for a wide range of applications.

Can excimer lasers produce different pulse repetition rates?

Yes, excimer lasers can operate at different pulse repetition rates depending on the pumping mechanism, offering flexibility for different applications.