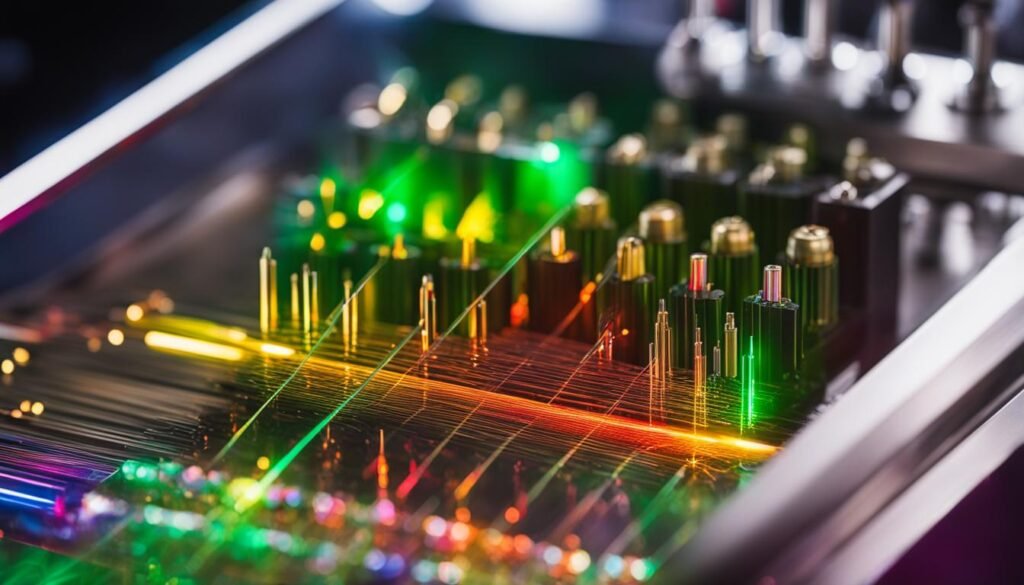

Fiber lasers have revolutionized various industries with their power, reliability, and compactness. These laser systems offer versatility and have the potential for further growth. Early fiber lasers had limitations in terms of power until the development of efficient pumping methods, such as distributed side-pumping, which unlocked their true potential.

Industrial fiber lasers are characterized by two stages: a power combiner and a brightness converter. The power combiner efficiently combines the multimode light from multiple laser diode pump packages, while the brightness converter converts the low-quality diode light into single-mode laser light. Fiber lasers can operate in different modes and at various wavelengths, depending on the active atoms doped in the fiber core.

With their ability to operate in different modes and wavelengths, fiber lasers have found applications across various industries, including automotive, aerospace, and medical devices.

Contents

- 1 The Versatility of Fiber Laser Applications

- 2 Fiber-Coupled Laser Diodes: A Versatile Solution

- 3 Specialty Fiber Components for High-Power Fiber Lasers

- 4 Managing Heat Load and Nonlinear Effects in Fiber Laser Systems

- 5 Conclusion

- 6 FAQ

- 6.1 What are fiber lasers?

- 6.2 How do fiber lasers work?

- 6.3 What modes can fiber lasers operate in?

- 6.4 What are the applications of fiber lasers?

- 6.5 What are fiber-coupled laser diodes?

- 6.6 What are the advantages of fiber-coupled laser diodes?

- 6.7 What are specialty fiber components?

- 6.8 How are heat load and nonlinear effects managed in fiber laser systems?

- 7 Source Links

Key Takeaways:

- Fiber lasers are powerful, reliable, and compact laser systems.

- The development of efficient pumping methods unlocked the true potential of fiber lasers.

- Industrial fiber lasers have two stages: a power combiner and a brightness converter.

- Fiber lasers can operate in different modes and at various wavelengths.

- Fiber lasers have applications in industries such as automotive, aerospace, and medical devices.

The Versatility of Fiber Laser Applications

Fiber lasers have a wide range of applications across different industries. Their high power, excellent beam quality, and fast processing speeds make them ideal for a variety of tasks.

One of the main applications of fiber lasers is in cutting and welding metals. Their precision and accuracy enable clean cuts and strong welds, making them essential in industries such as automotive, aerospace, and manufacturing. Fiber lasers are also used for other applications such as brazing, 3D printing, cladding, and heat treating.

Another popular use for fiber lasers is in laser marking, engraving, and surface cleaning. Their high power density allows for precise and detailed markings on various materials. Whether it’s marking serial numbers on metal parts or engraving designs on plastics, fiber lasers provide excellent results.

“Fiber lasers are preferred for their versatility and precise laser power delivery.”

In the medical field, fiber lasers are utilized for laser surgery due to their narrow linewidths and polarization options. They allow for highly controlled and minimally invasive procedures. Additionally, in scientific research, fiber lasers are valued for their short pulse durations, which enable the study of ultrafast processes at a molecular level.

The versatility of fiber laser applications makes them a preferred choice in many industries. Their ability to cut, weld, mark, engrave, and more, combined with their reliability and precision, has made them a staple in modern manufacturing and scientific research.

Fiber-Coupled Laser Diodes: A Versatile Solution

Fiber-coupled laser diodes have emerged as a highly versatile solution in various industries, offering precise and efficient laser power delivery. These laser systems utilize fiber optic cables to couple the output of laser diodes, providing several advantages for different applications.

One of the key benefits of fiber-coupled laser diodes is the circular and homogenized intensity profile they offer. This ensures a symmetric beam quality, enabling consistent and even laser power distribution. Additionally, fiber-coupled laser diodes provide high laser power and can easily be coupled with other fiber optic components, enhancing their versatility in different setups.

These versatile laser systems find extensive use in medical, industrial, and instrumentation applications. In industries, fiber-coupled diode lasers are utilized for laser cutting, welding, and marking processes. They are also widely employed in medical applications, including laser surgery and various medical procedures.

Fiber-Coupled Laser Diodes in Industrial Applications

Within industrial settings, fiber-coupled laser diodes play a crucial role in processes such as laser cutting, welding, and marking. The precise and efficient laser power delivery provided by these systems ensures optimal results and enhances productivity. Fiber-coupled laser diodes offer the flexibility to work with different materials, including metals, plastics, and composites, making them a versatile choice for various manufacturing applications.

| Laser Application | Advantages of Fiber-Coupled Laser Diodes |

|---|---|

| Laser Cutting | Highly precise and fast cutting with minimal heat-affected zones |

| Laser Welding | Efficient and reliable welding with excellent joint quality |

| Laser Marking | Highly accurate and permanent marking on a wide range of materials |

Fiber-Coupled Laser Diodes in Medical Applications

In the medical field, fiber-coupled laser diodes offer numerous advantages for laser surgery and other medical procedures. These systems provide precise control and delivery of laser power, ensuring safe and effective treatments. Fiber-coupled laser diodes are employed in a variety of medical applications, including dermatology, ophthalmology, and aesthetic treatments.

With their versatility and reliability, fiber-coupled laser diodes continue to play a significant role in advancing industrial processes and medical treatments. Their ability to deliver laser power with precision and efficiency makes them a preferred choice in various industries.

Specialty Fiber Components for High-Power Fiber Lasers

Fiber lasers have gained significant popularity in various industries due to their high-power capabilities and precise laser beam delivery. These lasers rely on specialty fiber components to generate and transmit high-power laser beams efficiently. These components play a crucial role in managing heat load, reducing nonlinear effects, and ensuring the overall performance and reliability of fiber laser systems.

One of the key components used in high-power fiber lasers is the mode field adapter (MFA). MFAs are designed to adjust the mode field diameter, allowing for efficient coupling and minimizing losses between different stages of the laser system. By optimizing the mode field, MFAs help reduce detrimental nonlinear effects like stimulated Brillouin scattering (SBS) and stimulated Raman scattering (SRS), which can disperse laser energy and impact the overall system performance.

Another important component in high-power fiber lasers is the power combiner. Power combiners are responsible for efficiently combining the output from multiple laser diode pump packages, maximizing the power output of the fiber laser system. By effectively distributing the laser energy, power combiners help achieve high-power levels while maintaining beam quality and minimizing thermal loading.

| Specialty Fiber Component | Function |

|---|---|

| Mode Field Adapter (MFA) | Adjusts mode field diameter, reduces losses, and manages nonlinear effects |

| Power Combiner | Efficiently combines laser diode outputs, maximizes power output |

These are just a few examples of the specialty fiber components used in high-power fiber lasers. Each component plays a critical role in ensuring the performance, reliability, and efficiency of the laser system. As advancements in fiber laser technology continue, we can expect further innovations in specialty fiber components, enabling even higher power levels and expanded applications for fiber laser systems.

Managing Heat Load and Nonlinear Effects in Fiber Laser Systems

Fiber laser systems face challenges in managing heat load and nonlinear effects, which can impact their performance and longevity. Heat load refers to the amount of heat generated during laser operation, which can lead to thermal damage and reduced efficiency if not properly managed. Nonlinear effects, on the other hand, occur when the laser energy interacts with the fiber and causes disruptions in the output beam.

To address heat load, various techniques are employed. One method is the use of end caps, which are short pieces of fused silica spliced to the fiber ends. These end caps reduce power density at the tips of fibers, preventing damage at the glass/air interface. By allowing the laser beam to expand, the power density is decreased, minimizing the risk of thermal damage. Another technique is the use of air-gap connectors, which dissipate heat and prevent damage to epoxy. These connectors help to maintain optimal operating temperatures and protect the fiber system from overheating.

Nonlinear effects, such as stimulated Brillouin scattering (SBS) and stimulated Raman scattering (SRS), can be managed through the use of specific components. Mode field adapters (MFAs) are employed to adjust the mode field diameter, reducing losses between different stages of the laser system. By optimizing the mode field diameter, the amount of energy that interacts with the fiber is controlled, minimizing the occurrence of nonlinear effects. Additionally, careful calibration of the laser system parameters can help mitigate these effects and ensure the smooth operation of the fiber laser system.

The Importance of Managing Heat Load and Nonlinear Effects

Efficient management of heat load and nonlinear effects is crucial for achieving high-power fiber laser systems that deliver consistent and reliable performance. By effectively dissipating heat and minimizing thermal damage, the longevity of the fiber laser system is extended, reducing maintenance and downtime. Furthermore, the reduction of nonlinear effects allows for improved beam quality and stability, enhancing the precision and accuracy of laser processing applications.

In summary, managing heat load and nonlinear effects in fiber laser systems is essential for ensuring optimal performance and longevity. Through the use of techniques such as end caps and air-gap connectors, heat load can be effectively addressed, preventing thermal damage and promoting efficient operation. Additionally, the implementation of mode field adapters and careful calibration of system parameters can minimize nonlinear effects and enhance beam quality. By prioritizing the management of heat load and nonlinear effects, businesses can maximize the potential of high-power fiber lasers for a wide range of applications.

| Advantages of Managing Heat Load | Advantages of Managing Nonlinear Effects |

|---|---|

| Prevents thermal damage | Enhanced beam quality |

| Extended system longevity | Improved stability |

| Reduced maintenance and downtime | Increased precision |

Conclusion

Fiber lasers have revolutionized various industries with their power, versatility, and precision. These lasers have found applications in cutting, welding, marking, engraving, and many other manufacturing processes, making them an invaluable tool in today’s technological landscape.

Another notable advancement is the emergence of fiber-coupled laser diodes as a versatile solution for delivering laser power. These diodes allow for efficient and precise laser beam delivery, making them ideal for applications across multiple industries, including medical, industrial, and instrumentation.

Furthermore, specialty fiber components play a crucial role in managing heat load, reducing nonlinear effects, and achieving high-power laser systems. These components, such as mode field adapters, combiners, and end caps, help optimize laser performance and ensure efficient power transmission.

With the continuous advancements in fiber laser technology, including power scaling, beam quality, and application-specific designs, the future of fiber lasers looks promising. By understanding the capabilities and applications of fiber lasers and utilizing the right components, businesses can harness the full potential of fiber laser technology for their specific needs.

FAQ

What are fiber lasers?

Fiber lasers are powerful, reliable, and compact laser systems that have revolutionized various industries.

How do fiber lasers work?

Fiber lasers operate by combining multimode light from multiple laser diode pump packages and converting it into single-mode laser light.

What modes can fiber lasers operate in?

Fiber lasers can operate in continuous wave, quasi-CW, nanosecond pulsed, and ultrafast pico- or femtosecond pulsed modes.

What are the applications of fiber lasers?

Fiber lasers are used in industries such as automotive, aerospace, and medical devices for cutting, welding, marking, engraving, and surface cleaning.

What are fiber-coupled laser diodes?

Fiber-coupled laser diodes are laser systems where the laser diode’s output is coupled into a fiber optic cable.

What are the advantages of fiber-coupled laser diodes?

Fiber-coupled laser diodes have a circular and homogenized intensity profile, high laser power, and easy coupling with other fiber optic components.

What are specialty fiber components?

Specialty fiber components are used to generate and transmit high-power laser beams and manage thermal load and nonlinear effects in fiber laser systems.

How are heat load and nonlinear effects managed in fiber laser systems?

Heat load is managed through the use of end caps and air-gap connectors, while nonlinear effects are reduced by components like mode field adapters.