Contents

Gas lasers are widely used in various fields such as telecommunications, medical diagnostics, and material processing. This comprehensive guide explores the applications and advantages of gas lasers, highlighting their unique features and benefits.

Key Takeaways:

- Gas lasers have diverse applications in fields like telecommunications, medicine, and material processing.

- They offer unique advantages such as high efficiency, excellent spatial coherence, and a wide range of output wavelengths.

- Gas lasers played a significant role in the evolution of laser technology since their emergence in the 1960s.

- Types of gas lasers include helium-neon lasers, carbon dioxide lasers, and argon-ion lasers, each with specific applications.

- The principles of gas laser operation revolve around population inversion, stimulated emission, and optical feedback mechanisms.

Fundamentals of Gas Lasers

Gas lasers are a type of laser technology that harnesses the properties of a gaseous medium to generate coherent light. Understanding the fundamental principles of gas lasers is essential to grasp their working mechanism and applications in various fields.

Gaseous Medium

The main component of gas lasers is the gaseous medium, which serves as the active laser medium. Common gases used in these lasers include helium, neon, argon, krypton, and carbon dioxide. Each gas exhibits specific characteristics, such as the emission wavelength and energy efficiency, making it suitable for particular applications.

Population Inversion

To achieve lasing action, a critical step in gas lasers is the creation of population inversion. This occurs when a higher number of atoms or molecules in the gaseous medium occupy an excited state rather than the ground state. Population inversion is crucial for stimulated emission, where photons are emitted in phase and amplify the light signal.

Optical Feedback Mechanism

The optical feedback mechanism is an integral part of gas lasers. It involves the use of mirrors placed at the ends of the laser cavity to create a resonant optical path. The mirrors reflect the emitted photons back into the medium, further amplifying the light and maintaining the coherence of the laser beam.

Excitation Mechanisms

Gas lasers require an external energy source to excite the gaseous medium and achieve population inversion. Different excitation mechanisms are used, such as electrical discharge, optical pumping, or chemical reactions. These mechanisms introduce energy into the gas, causing the atoms or molecules to transition to higher energy levels.

Cooling and Regeneration

Gas lasers produce heat during operation due to energy absorption in the gaseous medium. Cooling systems are implemented to maintain the optimal operating temperature and prevent overheating. Additionally, gas lasers require regeneration processes, where the gaseous medium is replenished or recirculated to maintain its effectiveness.

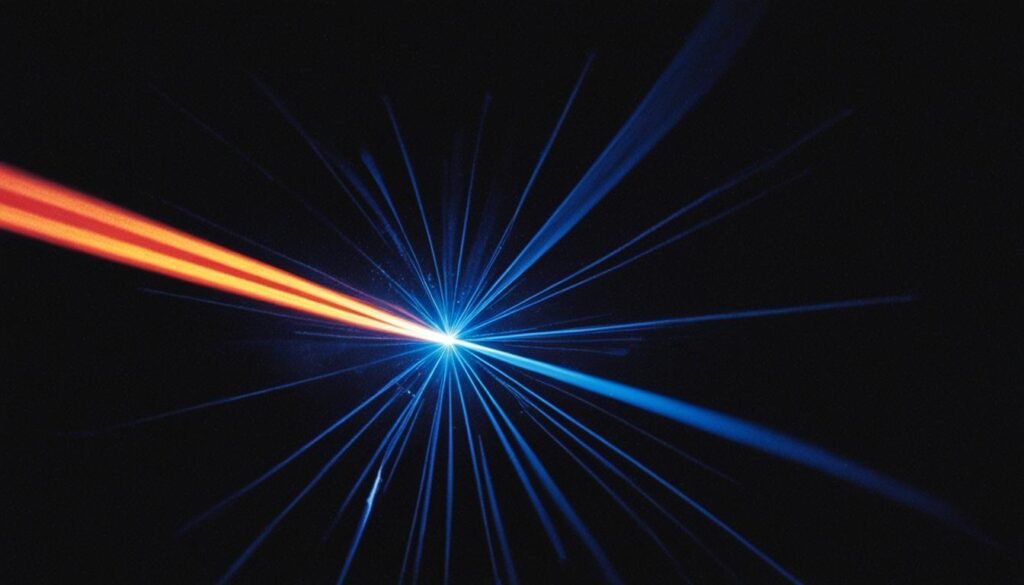

The image above showcases the intricate components and operations involved in gas lasers. It visually represents the key elements discussed, reinforcing the understanding of gas laser technology.

Now that we have explored the fundamentals of gas lasers, we can move on to understanding their historical significance and contextual background.

Historical Context

The evolution of laser technology has been greatly influenced by the development and advancements of gas lasers. In this section, we explore the historical context of gas lasers and their significant contributions to various applications.

“Gas lasers have revolutionized the field of laser technology, paving the way for numerous applications and discoveries.” ~ Dr. Richard Anderson, Laser Technology Expert

In the 1960s, gas lasers emerged as a groundbreaking innovation, marking a new era in laser research and development. These lasers utilized gaseous mediums to generate intense, coherent beams of light with various wavelengths. As a result, they quickly found applications in a wide range of industries and scientific disciplines.

One of the earliest and most influential gas lasers is the helium-neon (HeNe) laser. Introduced in 1961, the HeNe laser became widely recognized for its stability, low power requirements, and the ability to emit a bright red beam. This led to its adoption in fields such as spectroscopy, holography, and barcode scanning.

In the late 1960s, the carbon dioxide (CO2) laser emerged as a game-changer, thanks to its high power output and its ability to emit infrared radiation. The CO2 laser found applications in industry, particularly in material processing and cutting.

However, it was the excimer laser that dominated the gas laser landscape in the late 20th century. Developed in the 1970s, excimer lasers produce short-wavelength ultraviolet light, enabling precise and controlled ablation of materials. They have since become essential tools in ophthalmology, semiconductor manufacturing, and micromachining.

Key Milestones in Gas Laser History

Here are some notable milestones in the history of gas lasers:

- 1961: Introduction of the helium-neon (HeNe) laser

- 1964: First demonstration of the carbon dioxide (CO2) laser

- 1970: Development of the nitrogen laser, expanding gas laser capabilities

- 1975: Discovery of the pulsed dye laser, offering tunable wavelength capabilities

- 1982: Introduction of the excimer laser, revolutionizing laser materials processing

Gas lasers have undoubtedly shaped the landscape of laser technology, uncovering new possibilities and enabling significant advancements. Their historical significance remains profound, as they continue to play a vital role in numerous scientific, industrial, and medical applications.

Gas lasers have had a profound impact on laser technology.

| Gas Laser Type | Year of Invention | Main Applications |

|---|---|---|

| Helium-Neon (HeNe) Laser | 1961 | Spectroscopy, Holography, Barcoding |

| Carbon Dioxide (CO2) Laser | 1964 | Material Processing, Cutting |

| Excimer Laser | 1982 | Ophthalmology, Semiconductor Manufacturing, Micromachining |

Types of Gas Lasers

Gas lasers come in various types, each with their own distinct characteristics and emission spectra. This section will explore different types of gas lasers and their applications in various industries.

Neutral Atom Lasers

Neutral atom lasers are a type of gas laser that rely on neutral atoms as the lasing medium. Two commonly used neutral atom lasers are helium-neon lasers and metal vapor lasers.

“Helium-neon lasers are one of the most widely used types of gas lasers. They emit visible red light and have applications in areas such as barcode scanning, alignment, and laser pointers.”

Metal vapor lasers, on the other hand, use metallic elements, such as copper or gold, as the lasing medium. These lasers emit various wavelengths depending on the metal used and find applications in scientific research and materials processing.

Ion Lasers

Ion lasers utilize ions as the lasing medium, which results in their distinctive emission spectra. Argon-ion lasers and krypton-ion lasers are two examples of ion lasers.

“Argon-ion lasers emit blue-green light and have applications in medical and scientific research, including flow cytometry and confocal microscopy.”

Krypton-ion lasers, on the other hand, emit a mix of violet and yellow-green light and are used in applications such as laser light shows and spectroscopy.

The image above illustrates the different types of gas lasers and their emission spectra.

In summary, gas lasers encompass a variety of types, each with unique characteristics and applications. Neutral atom lasers like helium-neon lasers and metal vapor lasers, as well as ion lasers like argon-ion lasers and krypton-ion lasers, all play a significant role in various industries.

Principles of Operation of Gas Lasers

Gas lasers operate based on specific principles that involve the excitation of gas atoms to achieve population inversion. These principles are essential for understanding how gas lasers function and produce coherent light.

There are several key components and processes involved in the operation of gas lasers:

- Electrical Discharge Excitation: Gas lasers require an external source of energy to excite the gas atoms. This is typically achieved through electrical discharge excitation, where an electrical current is passed through the gas medium. This excitation process raises the energy levels of the gas atoms, preparing them for lasing action.

- Stimulated Emission: Once the gas atoms are excited, they enter a state of population inversion. In this state, a greater number of atoms occupy higher energy levels than lower energy levels. When a photon of the correct energy interacts with an excited atom, it stimulates the emission of additional photons with the same energy and direction. This process amplifies the initial photon, resulting in the coherent emission of laser light.

- Optical Feedback Mechanism: Gas lasers utilize mirrors to create an optical feedback mechanism. One mirror allows a small portion of the emitted light to pass through, while the other mirror reflects the light back into the laser cavity. This creates a feedback loop, allowing the stimulated emission to be amplified and sustained, forming a coherent beam of laser light.

In summary, gas lasers operate by exciting gas atoms through electrical discharge excitation, achieving population inversion, and utilizing mirrors to form an optical feedback mechanism. This enables the generation of coherent laser light that has applications in various fields such as telecommunications, scientific research, and industrial processes.

Applications and Modern Uses

Gas lasers have a wide range of applications across various sectors, playing a vital role in industrial processes, medical treatments, and scientific research. Let’s explore the diverse applications of gas lasers and the recent advancements in this field.

Gas Laser Applications in the Industrial Sector:

In the industrial sector, gas lasers are utilized for material processing tasks such as cutting and welding. The high energy density and precise beam control of gas lasers make them ideal for these applications. They offer advantages like faster processing times, improved accuracy, and the ability to work with a wide range of materials.

Gas Laser Applications in Medicine:

Gas lasers have revolutionized medical treatments, particularly in laser surgery and skin treatments. They are used for procedures like laser skin resurfacing, tattoo removal, and hair removal. Gas lasers offer precise targeting, minimal scarring, and reduced healing time, making them valuable tools for dermatologists and cosmetic surgeons.

Gas Laser Research Advancements:

The use of gas lasers in scientific research continues to expand. Gas lasers are crucial in spectroscopy, enabling detailed analysis of the structure and composition of various materials. They are also employed in holography, allowing the creation of 3D images and recording intricate patterns. Recent advancements in gas laser technology have further improved their precision, power output, and wavelength range, opening up new possibilities for research in areas such as quantum physics and nanotechnology.

“Gas lasers have been instrumental in advancing scientific research. Their precise and powerful beams have enabled breakthroughs in spectroscopy and holography, contributing to our understanding of complex materials and phenomena.”

Recent Advancements in Gas Laser Technology

Gas laser technology has witnessed significant advancements in recent years, enhancing their capabilities and expanding their applications. These advancements include:

- Development of new gas mixtures that offer improved efficiency and output power.

- Miniaturization of gas lasers, making them more compact and portable.

- Integration of gas lasers with other technologies, such as fiber optics and robotics, for enhanced functionality.

- Improved cooling and regeneration processes, increasing the reliability and lifespan of gas laser systems.

These advancements in gas laser technology have propelled research and industrial applications to new heights, making gas lasers indispensable tools in multiple sectors.

| Industry | Application |

|---|---|

| Industrial | Cutting and welding of materials |

| Medical | Laser surgery, skin resurfacing, tattoo removal |

| Scientific Research | Spectroscopy, holography |

Gas lasers have made significant contributions across industries, from shaping the manufacturing landscape to redefining medical treatments and enabling cutting-edge scientific research. With ongoing advancements in gas laser technology, we can expect even more innovative applications and breakthroughs in the future.

Advantages and Limitations of Gas Lasers

Gas lasers offer several advantages that make them a popular choice in various industries. These advantages include:

- High efficiency: Gas lasers are known for their high conversion efficiency, transforming electrical energy into laser light with minimal losses.

- Excellent spatial coherence: Gas lasers produce a tightly focused and collimated beam, making them ideal for applications that require precise control and accuracy.

- Wide range of output wavelengths: Gas lasers can emit light across a broad spectrum, allowing for versatility in different applications and research fields.

However, gas lasers also have some limitations that should be considered:

- High voltages: Gas lasers often require high voltages to initiate and maintain the lasing process, which can be challenging to achieve and may require additional power supplies.

- Complexity and cost of gas refill: Gas lasers rely on specific gas mixtures, and the process of refilling or replacing these gases can be complex and costly.

- Potential hazards: Certain gases used in gas lasers, such as carbon dioxide or argon, can pose safety risks if mishandled or if there are leaks in the laser system.

| Advantages of Gas Lasers | Limitations of Gas Lasers |

|---|---|

| High efficiency | High voltages |

| Excellent spatial coherence | Complexity and cost of gas refill |

| Wide range of output wavelengths | Potential hazards |

Quote:

“Gas lasers provide efficient and precise laser beams, making them indispensable for applications requiring high-quality and tunable light sources.” – Dr. Elizabeth Ramirez, Laser Technology Expert

Future of Gas Lasers

Despite the popularity of solid-state lasers and diode lasers, gas lasers continue to be indispensable in many specialized applications. With ongoing advancements in technology, the future of gas lasers holds promising developments and exciting possibilities.

Improved Efficiency and Power Output

Gas lasers have already demonstrated impressive efficiency and power output in various applications. However, ongoing research and innovation aim to enhance these qualities even further. Scientists and engineers are continually exploring new laser designs, refining optical components, and optimizing laser cavity geometries to increase the efficiency and power output of gas lasers.

By harnessing the potential of advanced cooling techniques and employing novel gas mixtures, future gas lasers are expected to achieve higher power levels while maintaining excellent beam quality. This enhanced efficiency and power output will enable gas lasers to meet the growing demands of industries such as manufacturing, aerospace, and defense.

Discovery of New Gas Mixtures

The discovery and utilization of new gas mixtures are key areas of research in gas laser development. Researchers are actively exploring different gas combinations to expand the range of available emission wavelengths and improve laser performance.

By identifying novel gas mixtures and optimizing their properties, scientists can develop gas lasers that cover a broader spectrum of wavelengths and offer improved characteristics such as higher power, better stability, and increased lifetime. These advancements will open up new possibilities for applications in fields like spectroscopy, environmental monitoring, and telecommunications.

Continued Relevance and Potential Developments

Gas lasers have a rich history of contributions to several scientific and industrial domains. Despite the emergence of alternative laser technologies, gas lasers continue to possess unique qualities that make them irreplaceable in certain specialized applications.

Gas lasers have proven their worth in fields such as scientific research, telecommunications, and medical diagnostics.

As technology continues to evolve, researchers foresee further developments in gas laser technology. These potential advancements include miniaturization to enable more portable gas laser devices, improved beam shaping and steering capabilities, and the integration of gas lasers with other technologies, such as quantum technology and nanophotonics.

The ongoing relevance of gas lasers, coupled with the drive for innovation, ensures a bright future for this versatile laser technology.

| Advantages | Limitations |

|---|---|

| Wide range of output wavelengths | High voltage requirement |

| High efficiency | Complex and costly gas refill process |

| Excellent spatial coherence | Potential hazards associated with certain gases |

Conclusion

In conclusion, gas lasers serve as indispensable tools in various industries and research fields. With their unique capabilities and advantages, gas lasers enable precise and efficient operations in specific applications. This comprehensive guide has explored the fundamentals, historical context, types, operation principles, applications, advantages, limitations, and future prospects of gas lasers. By understanding these aspects, professionals can leverage gas laser technology to drive advancements and innovation in multiple sectors.

Gas lasers offer a flexible and versatile solution for a wide range of tasks, from telecommunications and medical diagnostics to material processing and scientific research. Their ability to generate coherent and intense beams of light at specific wavelengths makes them ideal for precise cutting, welding, laser surgery, spectroscopy, and holography. Gas lasers also continue to evolve, with ongoing research and development focused on enhancing efficiency, power output, and the discovery of new gas mixtures.

While gas lasers come with advantages such as high efficiency and excellent spatial coherence, they also have limitations. The requirements for high voltages, complexity and cost of gas refills, as well as potential hazards associated with certain gases, must be carefully considered. Despite these limitations, gas lasers remain an important part of the laser technology landscape, offering specialized capabilities that cannot be easily replicated by other laser types.

In summary, gas lasers provide immense value in various applications and research endeavors. This article has provided a comprehensive overview of gas lasers, covering their key aspects from the fundamentals to their current and future applications. By harnessing the unique features of gas lasers, professionals can continue to push the boundaries of technological advancements and contribute to the progress of multiple fields.

FAQ

What are gas lasers?

Gas lasers are lasers that use a gaseous medium to produce coherent light. They operate by achieving a population inversion in the gaseous medium, leading to stimulated emissions of photons.

What are some applications of gas lasers?

Gas lasers have a wide range of applications, including telecommunications, medical diagnostics, material processing (such as cutting and welding), laser surgery, spectroscopy, and holography.

What are the advantages of using gas lasers?

Gas lasers offer advantages such as high efficiency, excellent spatial coherence, and a wide range of output wavelengths. They are also suitable for specialized applications in various industries.

What are the types of gas lasers?

There are different types of gas lasers, including helium-neon lasers, carbon dioxide lasers, argon-ion lasers, and krypton-ion lasers. Each type has unique characteristics and emission spectra.

How do gas lasers work?

Gas lasers operate by using external energy to excite the gas atoms, creating a population inversion. When the atoms transition back to their ground state, they emit coherent light.

What are the limitations of gas lasers?

Gas lasers require high voltages, complex gas refill procedures, and can be hazardous for certain gases. Additionally, other laser technologies, such as solid-state lasers and diode lasers, have gained popularity in some applications.

What is the future of gas lasers?

Gas lasers are expected to continue evolving with advancements in technology, improving efficiency, power output, and the discovery of new gas mixtures. They will remain relevant in specialized applications.