Contents

Source: Coherent

Understanding Laser Ablation

Laser ablation is a sophisticated technique used to remove material from a solid surface through the application of intense laser light. This process is a critical component of subtractive laser material processing, including applications such as laser engraving, cutting, and drilling.

Applications of Laser Ablation

Laser ablation is a versatile process with numerous applications across various fields:

Material Processing

In laser machining, processes such as cutting, drilling, and milling require the removal of material. Laser engraving, often used for marking, involves removing material to a specific depth with precision. This is achieved through a series of laser pulses, which are slightly shifted in position to ensure even removal. This technique is applicable to a variety of materials, including metals, ceramics, glasses, and polymers.

Surface Modification

Laser ablation is used to microtexture machine parts, enhancing their performance by reducing friction, especially in components like cylinders and pistons in engines. It also plays a role in laser cleaning, where unwanted material is selectively removed without damaging the underlying substrate.

Thin-film Photovoltaics

In the production of thin-film photovoltaic cells, laser ablation is used to insulate boundaries and create contacts by removing specific layers of material.

Medical Applications

In medicine, laser ablation enables precise surgical procedures, such as removing tumors, with minimal impact on surrounding tissues. It’s also used in dentistry to selectively remove caries-affected tissue while preserving healthy tooth structure.

The Physics of Laser Ablation

Absorption of Laser Light

The effectiveness of laser ablation hinges on the absorption of laser light. The wavelength is chosen to ensure that absorption occurs over a short distance, concentrating energy in a small volume and minimizing reflection losses. Near-infrared lasers are commonly used due to their availability and cost-effectiveness. However, for better absorption in materials like copper, frequency doubling techniques can be employed to shift the laser light to a more absorbent wavelength.

Ejection of Material

Material removal in laser ablation often involves vaporization. At moderate intensities, materials may melt, with vapor pressure or gas jets aiding in expulsion. Higher intensities lead to vaporization, forming a plume that may interact with laser light, sometimes forming a plasma that can either hinder or assist the ablation process.

Thermal Conduction and Pulse Duration

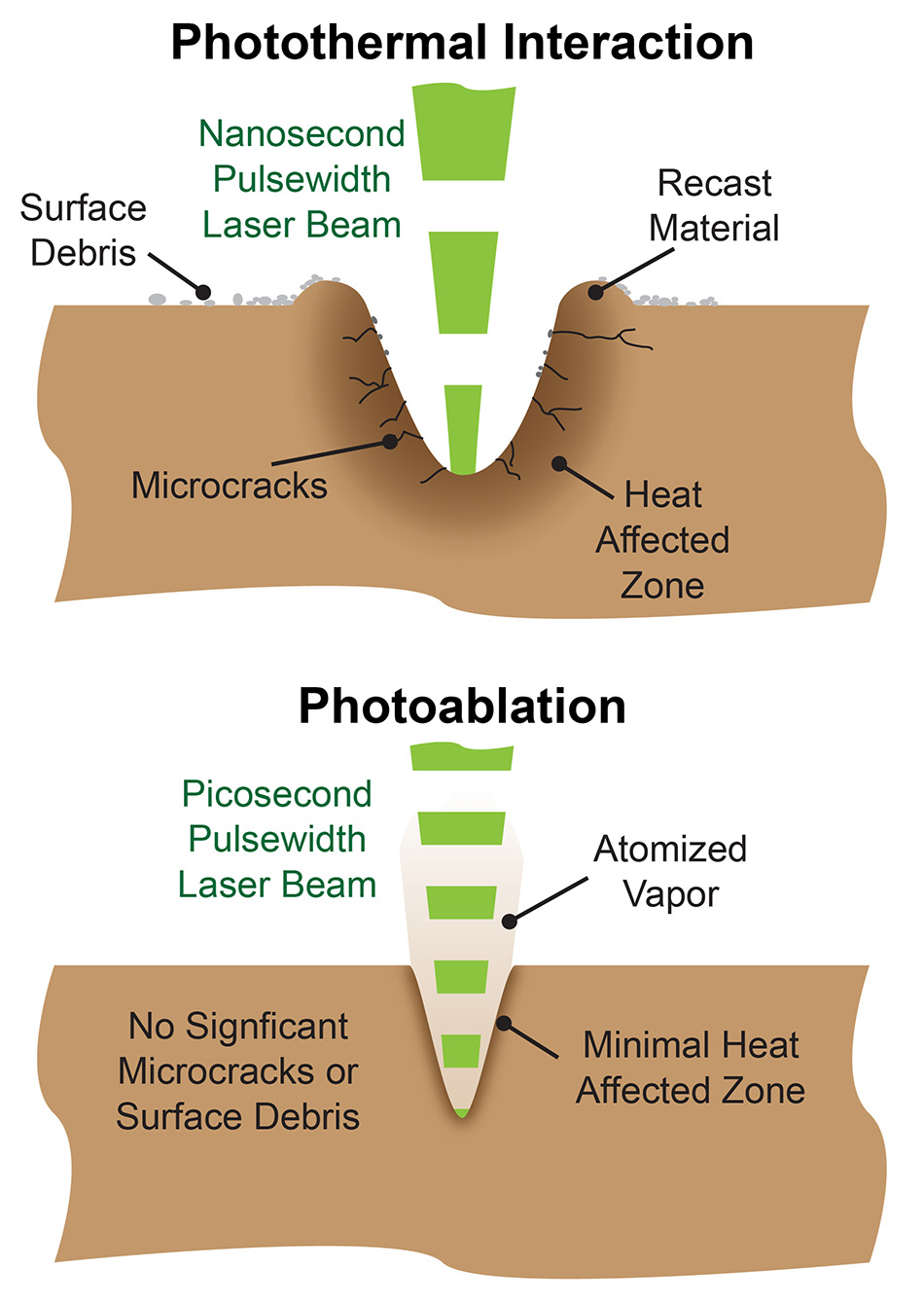

Minimizing thermal conduction is crucial to maintain the quality of the ablated material. This is achieved using short or ultrashort laser pulses, reducing the heat-affected zone (HAZ). Nanosecond lasers are cost-effective but less precise, whereas picosecond and femtosecond lasers offer higher precision by limiting heat transfer to surrounding areas.

Ablation Threshold and Efficiency

Effective ablation requires surpassing a threshold pulse energy. Efficiency varies with pulse energy, as too low energy results in minimal ablation, while excessive energy may lead to inefficient material removal. Beam shaping can optimize energy distribution, enhancing ablation efficiency.

Multiple Pulses and Processing Speed

Laser ablation often involves multiple pulses, with scanning techniques used to cover larger areas. Adjusting pulse repetition rates can control heat accumulation, balancing processing speed and quality. Burst mode lasers, which produce pulses in quick succession, can enhance efficiency by reducing heat accumulation.

Challenges and Future Directions

While laser ablation is energy-intensive, advancements in laser technology, such as fiber lasers, are improving efficiency and processing speed. Ongoing research aims to optimize laser systems for higher output power without compromising pulse quality, making laser ablation more economically viable for various applications.

Conclusion

Laser ablation is a powerful technique with diverse applications across industries. Understanding its principles and challenges is essential for optimizing its use in material processing and beyond. As laser technology continues to evolve, the potential for laser ablation to revolutionize manufacturing and medical procedures remains significant.

Source: Wikipedia

Feel free to comment your thoughts.