Contents

Source: Oxford Lasers

Understanding Laser Cladding in Metalworking

Laser cladding is a pivotal technique in the realm of metalworking, offering enhanced surface properties for various industrial applications. This process involves depositing a material onto a substrate to improve its resistance to wear, corrosion, and thermal stress. Let’s delve into the intricacies of this technique and explore its applications, processes, materials, and more.

Introduction to Laser Cladding

Cladding, in metalworking, refers to the deposition of a material onto another to form a protective layer. Laser cladding specifically employs a laser beam as the heat source to melt the cladding material, which forms a metallurgical bond with the substrate without melting it. This technique is highly valued for its precision and efficiency.

Applications of Laser Cladding

Laser cladding is widely used to enhance the durability and longevity of machine parts. Industries facing challenges such as abrasion, corrosion, and thermal shocks benefit significantly from this technology. Typical applications include the refurbishment of turbine blades, gear wheels, and cutting tools, where laser cladding can restore or enhance surface properties.

Original Fabrication vs. Repair

The technique is versatile, allowing for both the initial fabrication of parts and subsequent repair or refurbishment. Claddings can be applied to extensive surfaces or targeted to specific, critical areas that require reinforcement.

Laser Cladding Processes

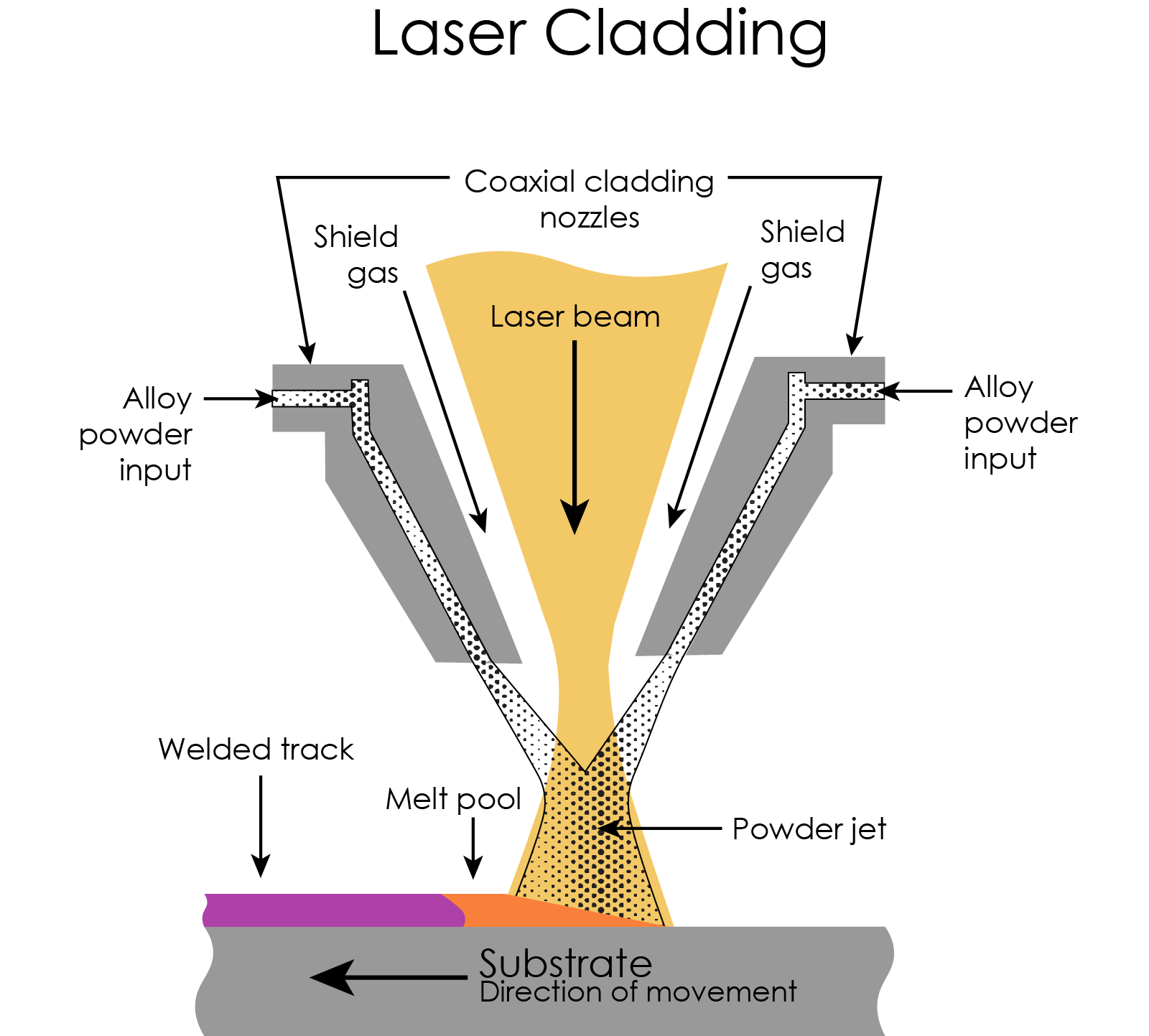

The laser cladding process involves moving a laser processing head over the substrate while feeding the cladding material into the laser’s focal area. The absorbed laser energy melts the cladding material, which solidifies quickly to form a robust bond with the base material. Process parameters such as laser power, spot size, and movement speed are crucial for optimal results.

Material Supply Methods

Cladding materials are typically supplied as powder or wire. The delivery method can be coaxial, where the material feed is integrated into the processing head, or lateral, where it is connected from the side. This choice depends on the specific application and desired outcomes.

Material Considerations

Common cladding materials include iron alloys, nickel, cobalt, and titanium, which are selected based on their melting points relative to the substrate. The choice of material impacts the cladding’s resistance to wear and thermal stress, making it a critical factor in the process.

Types of Lasers Used

Various lasers can be employed in cladding, including CO2 lasers, solid-state lasers, and direct diode lasers. Direct diode lasers are particularly popular due to their high efficiency. Continuous-wave laser operation is generally sufficient, with moderate optical intensity requirements.

Comparative Techniques

Laser cladding is often compared to laser plating and laser coating. While laser plating involves thinner layers, laser coating offers a broader material choice. Another related method is pulsed laser deposition, which is distinct in its use of a vacuum chamber and a pulsed ultraviolet beam to deposit materials.

Conclusion

Laser cladding is an advanced technique that significantly enhances the performance and lifespan of metal components. Its precision, adaptability, and efficiency make it an invaluable tool in modern metalworking. Understanding its processes and material considerations is essential for leveraging its full potential in industrial applications.

Source: YouTube

Feel free to comment your thoughts.