Contents

Source: Nutech

Laser Coating Techniques: Advancements and Applications

Laser coating techniques have revolutionized the way materials are coated, offering enhanced durability, functionality, and efficiency. This blog post explores the various laser-aided methods used for coating applications, the materials involved, and the numerous benefits they provide across different industries.

Understanding Laser Coating Processes

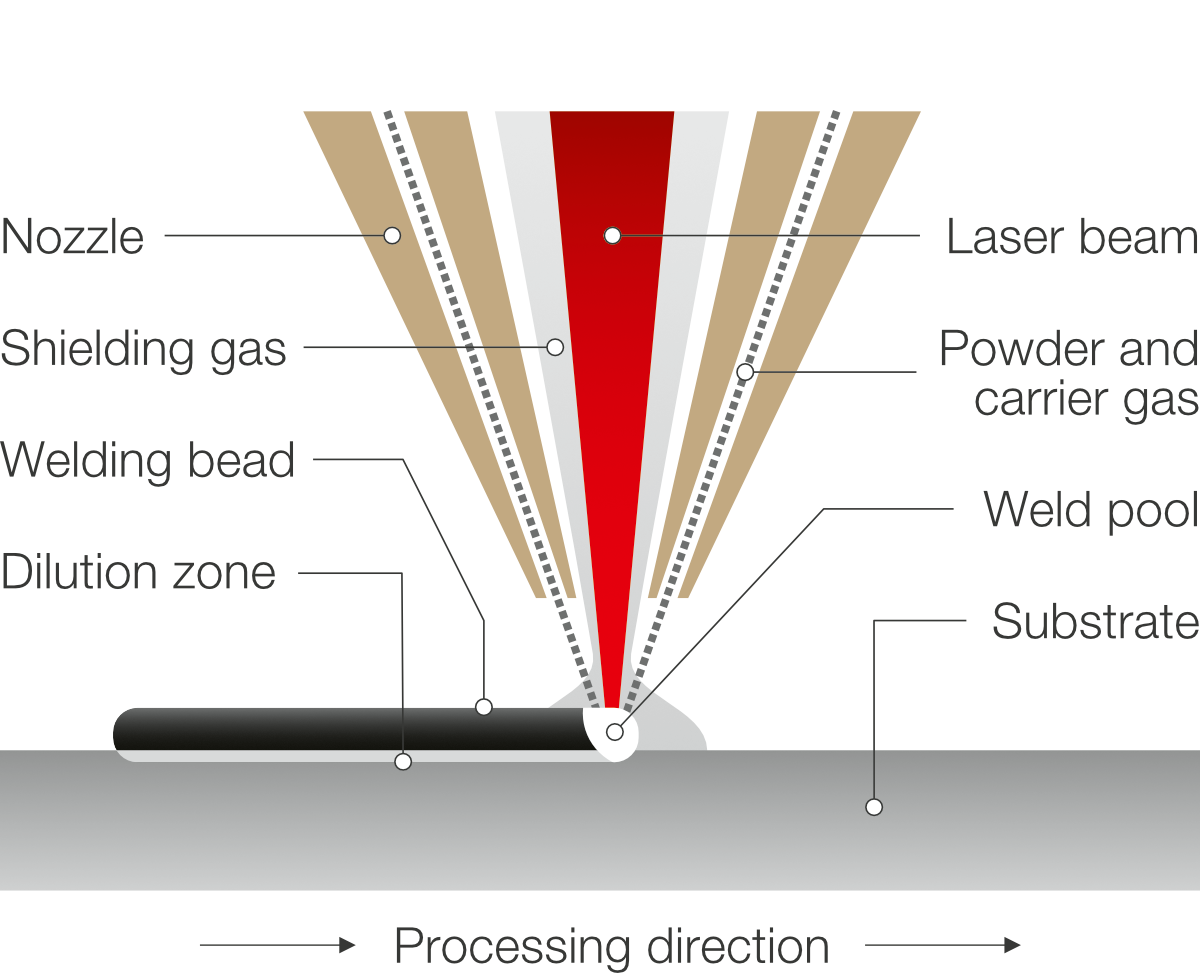

Laser coating is a sophisticated process that involves the precise application of coatings onto surfaces using laser technology. The process typically involves a laser processing head moving over a surface while the coating material is supplied to the beam’s focus region. The laser’s energy melts the material, which then solidifies upon cooling, forming a robust coating.

Material Supply and Integration

The coating materials are generally supplied in powder form and transported using a process gas that protects against oxidation. The material feed can be integrated into the laser processing head or connected laterally. Alternatives such as wire, tape, or paste can also be used as coating materials.

Alternative Coating Methods

For thicker coatings, spraying methods are employed where the material is converted into a spray before reaching the surface. Laser-aided methods enhance the quality of these coatings, sometimes using laser post-processing for improved results.

Process Optimization

Optimizing parameters such as laser power, spot size, and movement speed is crucial for achieving the best results. Automated laser coating machines can control these parameters, adapting them as needed for different applications.

Coating Materials and Their Applications

Laser coating techniques can apply a wide range of materials, including metallic alloys, carbides, and ceramics. Each material offers unique properties such as electrical conductivity, mechanical strength, and chemical resistance.

Metallic and Ceramic Coatings

Metallic coatings, often alloys, provide durability and thermal conductivity. Ceramic coatings, like carbide, offer high strength and resistance to extreme conditions. These coatings are crucial in industries such as aerospace, automotive, and medical technology.

Advantages of Laser Coating

Laser coating processes offer several advantages over traditional methods:

- High-quality coatings with uniformity and control over thickness and porosity.

- Flexibility in application, allowing for selective coating of specific areas.

- Lower substrate temperatures, enabling coating of temperature-sensitive materials.

- Potential for reduced environmental impact and increased efficiency.

Applications Across Industries

Laser coatings are predominantly used in industrial manufacturing, offering benefits such as increased lifespan and efficiency of components. For instance, turbine blades, brake discs, and mechanical tools benefit from enhanced durability and performance due to laser-applied coatings. In the medical field, coatings improve the biocompatibility of implants.

Future Developments

Ongoing research and development continue to expand the capabilities of laser coating technologies. Innovations such as the use of nanoparticulate materials and ultrashort laser pulses are paving the way for even more advanced and efficient coating processes.

In conclusion, laser coating techniques are a vital component of modern manufacturing, offering unparalleled benefits and versatility. As technology advances, these processes will continue to evolve, providing even greater efficiency and sustainability across various industries.

This blog post provides a comprehensive overview of laser coating techniques, discussing their processes, materials, advantages, and applications across industries. The content is structured with headings and subheadings to enhance readability and understanding.

Source: ALOtec

Feel free to comment your thoughts.