Contents

Source: Fraunhofer-Institut für Lasertechnik ILT – Fraunhofer-Gesellschaft

Understanding Laser Drilling: Techniques, Applications, and Challenges

Introduction to Laser Drilling

Laser drilling is a crucial technique in industrial laser material processing, particularly in laser beam machining. It involves creating holes of various sizes in different materials, ranging from metals to ceramics and glasses. This method is especially useful for producing small diameter holes, often with high aspect ratios, which are challenging to achieve with traditional mechanical drilling methods.

Characteristics of Laser Drilled Holes

Laser drilling is typically used for holes with diameters up to a few millimeters, but it is also effective for much smaller diameters below 100 micrometers. In extreme cases, it can even produce sub-micrometer holes, known as micro-drilling. The holes may be blind, with a defined depth, or they may pass through the entire thickness of a material, such as metal plates.

One of the significant advantages of laser drilling is the ability to create holes with high aspect ratios. For example, a hole with a diameter of 50 micrometers can be drilled several millimeters deep into hard metals. Additionally, while the holes are often perpendicular to the workpiece surface, they can also be made at variable angles.

Materials Suitable for Laser Drilling

Laser drilling can be applied to a wide range of materials, including hard metals like stainless steel and titanium alloys, ceramics, glasses, semiconductors, and other crystals. In many cases, traditional drilling methods are not viable for such materials, making laser drilling an indispensable technique in various industries.

Applications of Laser Drilling

The applications of laser drilling are diverse, including the creation of very small diameter holes for machine parts such as injection nozzles in fuel injectors and inkjet printers. Larger holes are used for air cooling turbine blades, venting, and instrumentation purposes. In electronic manufacturing, laser drilling is essential for creating microvias in printed circuit boards and for contacting silicon solar cells.

Laser drilling is also used to create tiny holes with significant depth in hard and brittle materials like glass, sapphire, or ceramics. These materials would be difficult or impossible to process with conventional drilling methods. Additionally, laser drilling is employed to perforate polymer foils, metal foils, and paper at high speeds.

Technical Details of Laser Drilling

Pulsed Processing with Short or Ultrashort Pulses

Laser drilling relies on the ablation of material using intense laser light. Pulsed lasers are generally used, with pulse durations ranging from femtoseconds to milliseconds, depending on the material and other factors. Shorter pulses, especially in the high-intensity regime, enable “cold ablation,” minimizing thermal effects and reducing the heat-affected zone.

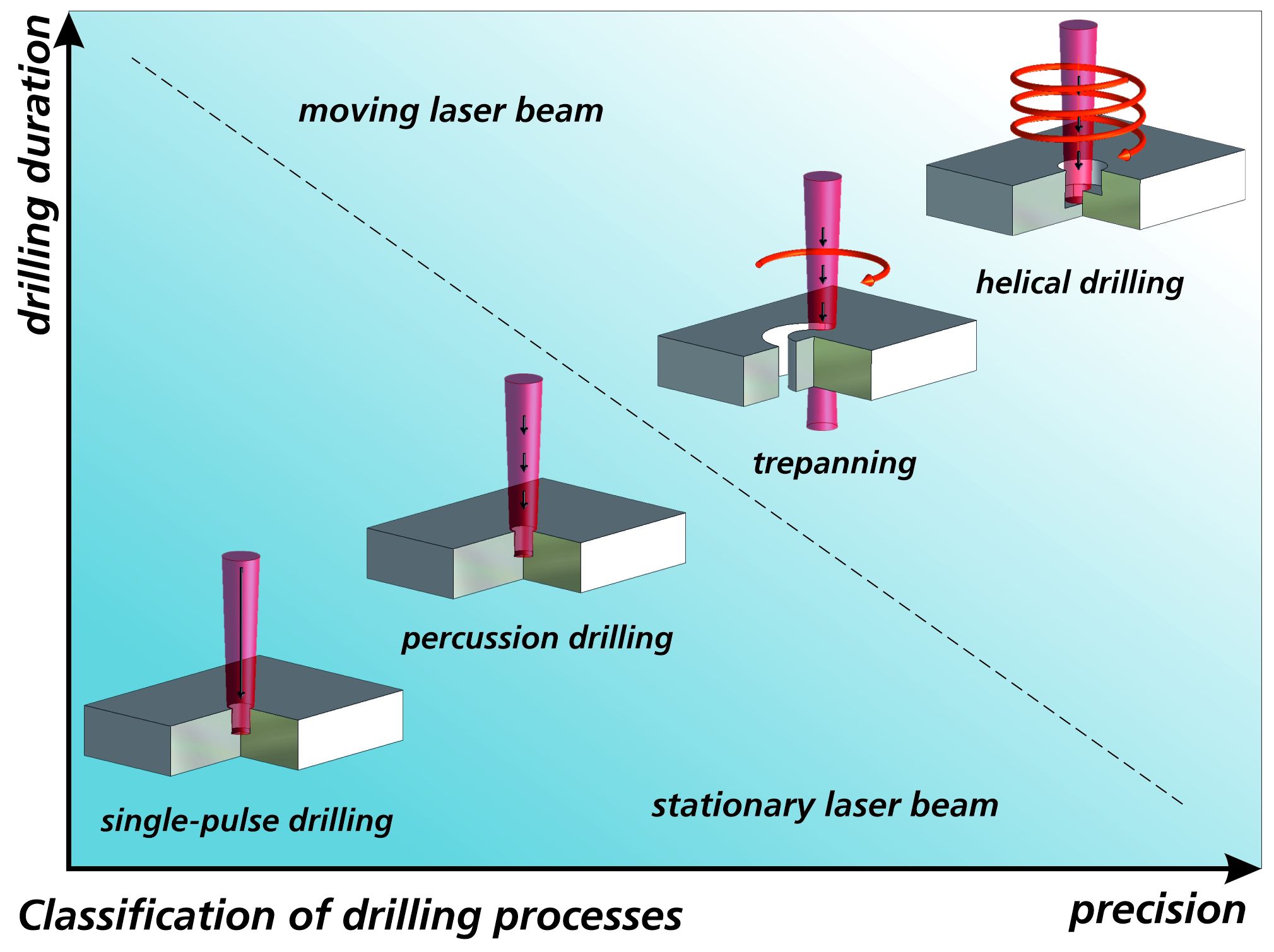

Single-pulse and Percussion Drilling

In some materials, a single intense laser pulse can create a hole, known as on-the-fly drilling. However, more often, a sequence of pulses, known as percussion drilling, is required. The pulse repetition rate and average power of the laser are crucial for achieving higher processing speeds.

Processing Efficiency and Quality

Efficient processing is usually achieved with longer high-energy pulses, where material expulsion occurs in liquid form. However, vapor expulsion, which requires higher laser energies, often results in better processing quality. A processing gas can be used to assist material expulsion and improve hole quality.

Challenges in Laser Drilling

Despite its advantages, laser drilling has limitations. Larger holes may require longer processing times due to the need to remove more material. Issues such as non-constant hole diameter, elliptical hole cross-sections, and recast formation can affect hole quality. These challenges can be mitigated by optimizing the drilling process, using advanced laser sources, and applying post-processing techniques.

Conclusion

Laser drilling is a versatile and essential technique in modern manufacturing, offering solutions for creating precise holes in a variety of materials. While it presents certain challenges, ongoing advancements in laser technology continue to enhance its efficiency and application scope. As industries demand increasingly complex and miniaturized components, laser drilling will remain a critical tool in achieving these goals.

Source: Lenox Laser

Feel free to comment your thoughts.