Contents

Source: tec-science

Understanding Laser Hardening in Modern Manufacturing

Laser hardening is a sophisticated technique used in the field of material processing, particularly for enhancing the surface properties of metals like steel and cast iron. This method leverages the precision and control offered by laser technology to improve hardness and durability, making it invaluable in industrial applications.

The Basics of Laser Hardening

Steel, primarily an alloy of iron and carbon, can contain additional elements such as chromium, vanadium, or titanium. These components influence the properties of steel, which can exist in various forms depending on its chemical composition and temperature. By employing rapid heating and cooling processes, steel can be transformed into different microstructures with distinct characteristics like hardness, strength, and ductility.

Principle of Laser Hardening

Laser hardening involves using a laser to heat the surface of carbon-rich steel (with a carbon content of at least 0.8%) to approximately 1000°C, just below its melting point. This process alters the steel’s microstructure, converting it into a form known as martensite, which is harder and more chemically resistant. The rapid cooling that follows the heating phase is crucial, as it prevents the carbon atoms from migrating, thereby maintaining the hard martensitic structure.

Application in Cast Iron

Similar techniques can be applied to cast iron, which contains more than 2% carbon. The transformation to martensite increases the surface hardness and improves the material’s resistance to wear and tear.

The Laser Hardening Process

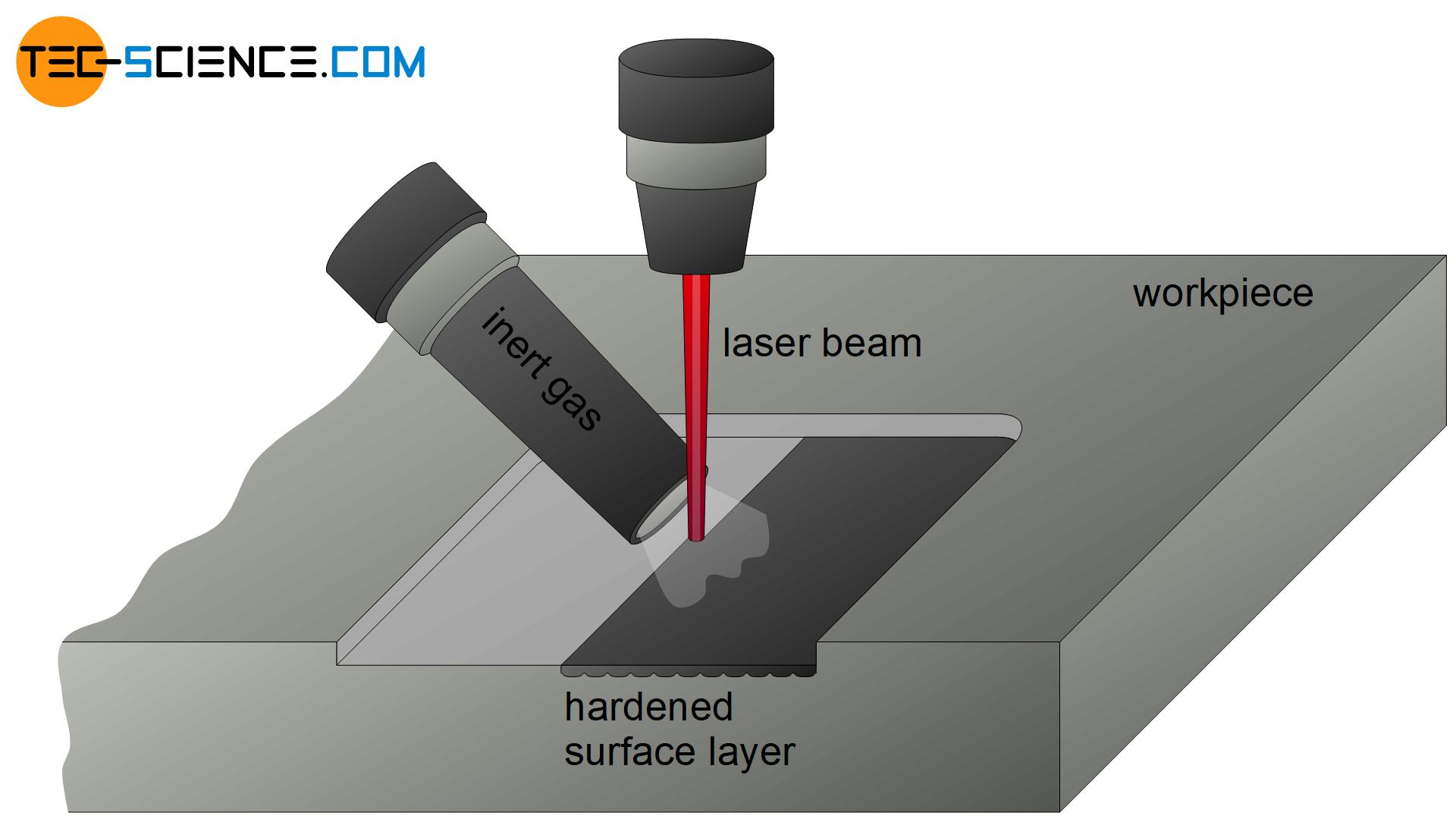

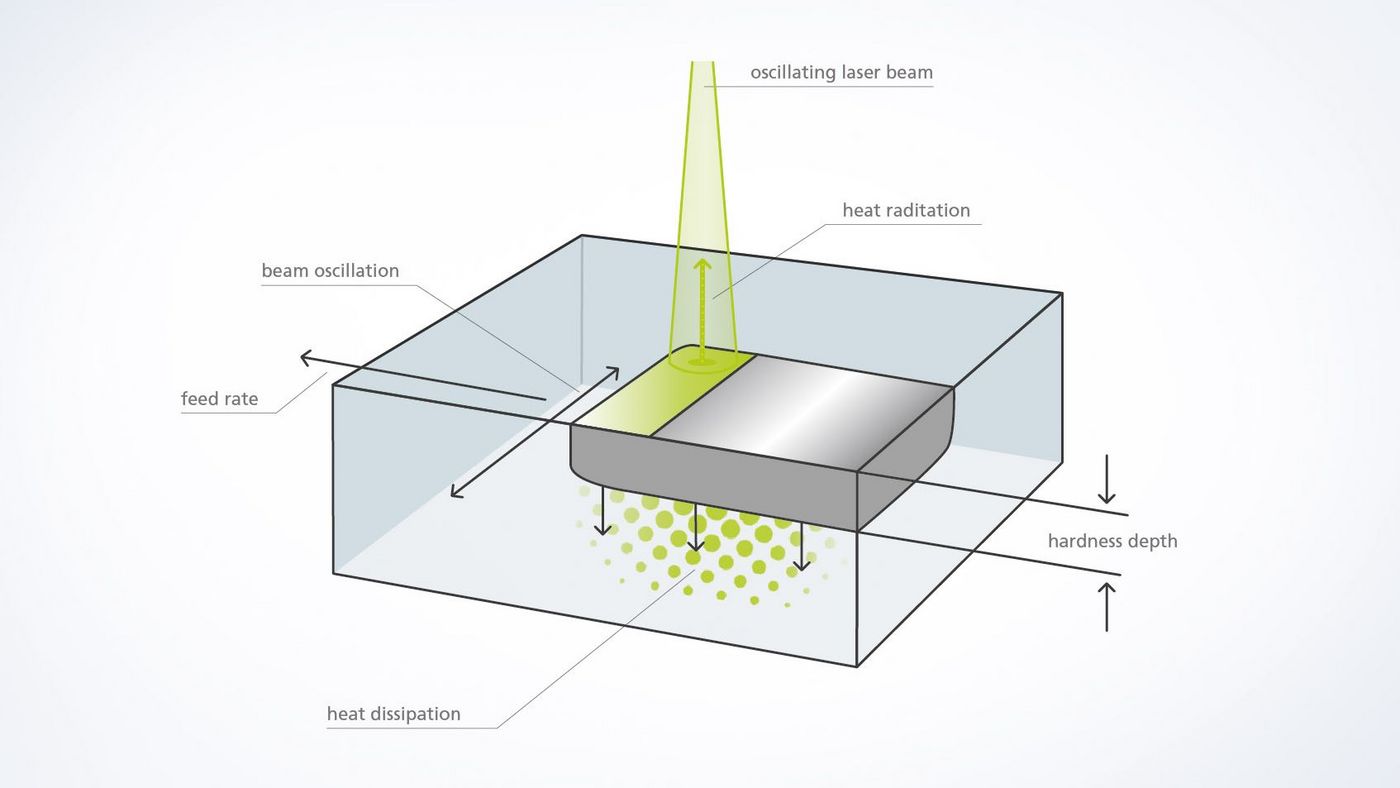

Laser hardening involves directing a laser beam onto the metal surface, heating it momentarily. The heat then diffuses into the material, and upon removal of the laser, the surface cools rapidly through self-quenching. This process can be applied selectively to small areas or scanned over larger surfaces, depending on the application requirements.

Advantages Over Traditional Methods

Compared to traditional hardening methods, laser hardening is significantly faster and more precise. It allows for targeted application of heat, reducing the need for additional processing. The shape of the treated components remains largely unchanged, and the process can be performed “on the fly” during movement, enhancing efficiency.

Laser Sources and Beam Profiles

The choice of laser source is critical in laser hardening. Direct diode lasers, known for their cost-effectiveness and high power efficiency, are commonly used. These lasers typically operate at wavelengths between 0.8 μm and 1 μm. Although metal surfaces reflect much of this light, techniques such as applying an absorptive coating or altering the surface microstructure can improve absorption.

Beam Profile Optimization

Flat-top beam profiles, which provide uniform intensity across the treated area, are ideal for laser hardening. These profiles ensure consistent temperatures, crucial for achieving uniform hardening. Laser scanners can be employed to tailor the beam profiles as needed.

Temperature Control and Process Gas

Maintaining precise temperature control is essential for achieving high-quality results. Continuous monitoring of the process temperature allows for automatic adjustments to the laser power or movement speed, ensuring consistency. Although a process gas is not necessary for surface protection, it is often used to protect the optics from contamination by fumes generated during the process.

Applications of Laser Hardening

Laser hardening is widely used in manufacturing machine components that must endure substantial forces, such as turbine blades, camshafts, and gear wheels. This technique is prevalent in the automotive and aerospace industries, where durability and performance are critical. By hardening only the surface, the process avoids increasing brittleness throughout the entire volume of the material.

Conclusion

Laser hardening is an advanced technique that enhances the durability and performance of metal components. Its precision, efficiency, and adaptability make it a vital tool in modern manufacturing, ensuring that components can withstand the rigorous demands of industrial applications.

Source: TRUMPF

Feel free to comment your thoughts.