Contents

- 1 Principles of Laser Ignition

- 2 Advantages of Laser Ignition

- 3 Laser Ignition Systems and Arrangements

- 4 Experimental Investigation of Laser Ignition

- 5 Comparison of Laser Ignition and Spark Plug Ignition

- 6 Challenges and Future of Laser Ignition

- 7 Conclusion

- 8 FAQ

- 8.1 What is laser ignition?

- 8.2 What are the advantages of laser ignition?

- 8.3 How does laser ignition compare to spark plug ignition?

- 8.4 How are laser ignition systems designed?

- 8.5 What experimental studies have been conducted on laser ignition?

- 8.6 What are the challenges of implementing laser ignition?

- 8.7 What is the future of laser ignition?

- 9 Source Links

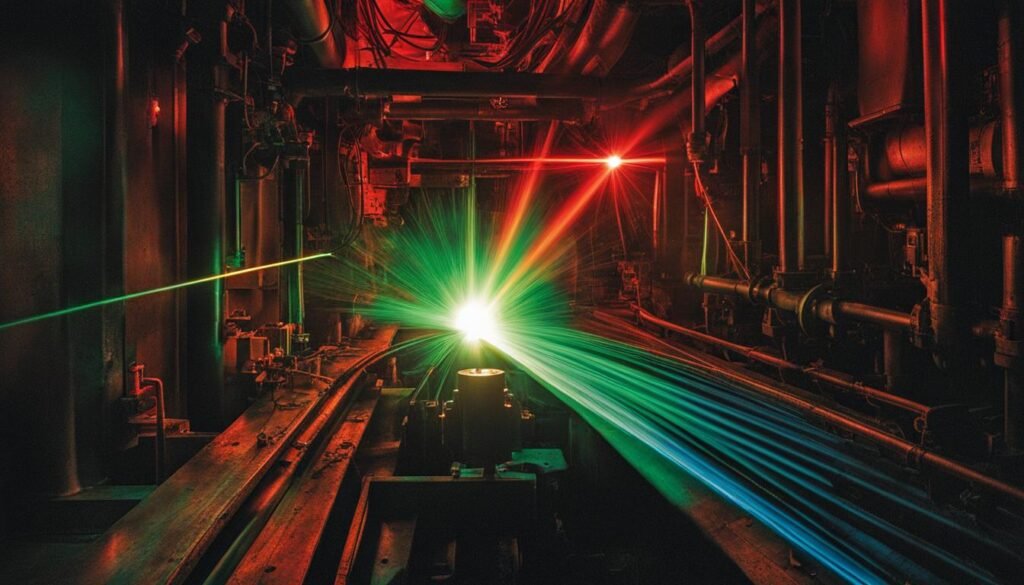

Laser ignition is a promising future ignition concept for internal combustion engines, offering benefits such as reduced pollutant emissions and improved engine efficiencies. It involves generating an igniting plasma using a focused pulsed laser beam. The pulse energy required for reliable ignition is typically around 10 mJ, with pulse durations of a few nanoseconds. The development of compact high-power laser systems that meet these specifications has been a focus of research. Different phases of laser ignition include electric breakdown and energy transfer, shock-wave generation, gasdynamic effects, chemical induction of branching chain reactions, and turbulent flame initiation. Plasma diagnostics, including high-speed Schlieren photography, have been used to observe these phases. Laser ignition has advantages such as performance-enhancing high effective mean pressures in the combustion chamber and the ability to ignite very lean mixtures and reduce NOx emissions.

Key Takeaways:

- Laser ignition offers reduced pollutant emissions and improved engine efficiencies.

- Pulse energy and duration are critical factors in laser ignition.

- High-speed Schlieren photography is used to observe different phases of laser ignition.

- Laser ignition enables the ignition of lean mixtures and reduces NOx emissions.

- Compact high-power laser systems are being developed for laser ignition in combustion.

Continue reading to discover the principles of laser ignition, its advantages over conventional ignition techniques, different laser ignition systems and arrangements, experimental investigations in laser ignition, a comparison with spark plug ignition, challenges in laser ignition, and its future prospects.

Stay tuned for more comprehensive insights into laser ignition in combustion.

Principles of Laser Ignition

Laser ignition is based on the principles of non-resonant gas breakdown and plasma formation. It involves the use of a tightly focused pulsed laser beam to induce a breakdown in the gas mixture, leading to the formation of a plasma that can ignite the combustible mixture. The process begins with initial electrons absorbing photons from the laser beam and gaining energy, which then leads to the ionization of gas molecules. This ionization process creates a plasma, which can ignite the surrounding mixture.

The ignition process of laser ignition consists of several stages, including electric breakdown and energy transfer, shock-wave generation and propagation, gasdynamic effects, chemical induction of branching chain reactions, and turbulent flame initiation. These stages are crucial for achieving reliable and efficient ignition. The minimum pulse energy required for ignition depends on various factors, such as the relative air/fuel ratio, temperature, and initial pressure. Additionally, laser ignition requires intensities of several 10^11 W/cm² in the focal region to ensure successful ignition.

Laser ignition principles are essential in understanding the mechanisms behind the process and optimizing the design of laser ignition systems. By harnessing the power of laser technology, researchers are unlocking the potential for more efficient and environmentally friendly combustion processes in internal combustion engines.

Advantages of Laser Ignition

Laser ignition offers numerous advantages over conventional ignition techniques. One of the key advantages is its ability to ignite very lean mixtures, which can result in reduced emissions, particularly of nitrogen oxides (NOx). The high effective mean pressures generated by laser ignition in the combustion chamber contribute to improved engine efficiency.

Furthermore, laser ignition allows for the use of lower flame temperatures, which can contribute to the reduction of NOx emissions. This temperature reduction is possible due to the precise control and rapid energy deposition provided by the laser beam. The flexibility of laser ignition also enables the implementation of multi-point ignition strategies, further optimizing the combustion process.

With its potential to enhance combustion efficiency and reduce emissions, laser ignition holds great promise for the future of internal combustion engines, paving the way for a more sustainable and cleaner transportation sector.

Advantages of Laser Ignition

Laser ignition offers several advantages over conventional ignition techniques. These advantages contribute to improved efficiency and reduced emissions, making it a compelling option for combustion processes.

“Laser ignition allows for performance-enhancing high effective mean pressures in the combustion chamber, resulting in improved efficiency.”

One of the key advantages of laser ignition is its ability to ignite very lean mixtures. This capability is crucial for achieving higher engine efficiencies and reducing pollutant emissions, particularly nitrogen oxides (NOx). By igniting lean mixtures, laser ignition enables more complete combustion, leading to improved fuel efficiency and lower emissions. In addition, laser ignition allows for the use of lower flame temperatures, which further contributes to reduced NOx emissions.

Another advantage of laser ignition is its flexibility in implementing multi-point ignition. Multi-point ignition involves igniting the fuel mixture at multiple locations within the combustion chamber. This approach can optimize the combustion process by promoting better flame propagation and reducing the occurrence of incomplete combustion. Laser ignition systems can be designed to provide precise control over the timing and location of ignition events, allowing for effective multi-point ignition strategies.

Advantages of Laser Ignition:

- Improved engine efficiency

- Lower NOx emissions

- Ability to ignite lean mixtures

- Flexibility for multi-point ignition

The advantages of laser ignition make it a highly promising technology for enhancing combustion processes in internal combustion engines. With its ability to improve efficiency and reduce emissions, laser ignition has the potential to revolutionize combustion technologies in the future.

| Advantages of Laser Ignition | Description |

|---|---|

| Improved engine efficiency | Laser ignition enables higher effective mean pressures in the combustion chamber, resulting in improved engine efficiency. |

| Lower NOx emissions | By igniting lean mixtures and allowing for lower flame temperatures, laser ignition contributes to reduced nitrogen oxides (NOx) emissions. |

| Ability to ignite lean mixtures | Laser ignition can reliably ignite very lean fuel-air mixtures, leading to improved fuel efficiency and reduced emissions. |

| Flexibility for multi-point ignition | Laser ignition systems can be designed to implement precise multi-point ignition strategies, optimizing combustion processes. |

Laser Ignition Systems and Arrangements

Laser ignition systems play a crucial role in the successful implementation of laser ignition technology in combustion processes. These systems are designed to generate and deliver the necessary laser pulses for ignition. There are various approaches to designing laser ignition systems, each with its unique advantages and considerations. Two common approaches include the use of laser spark plugs and the transmission of ignition pulses via fiber-optic cables.

Laser Spark Plugs

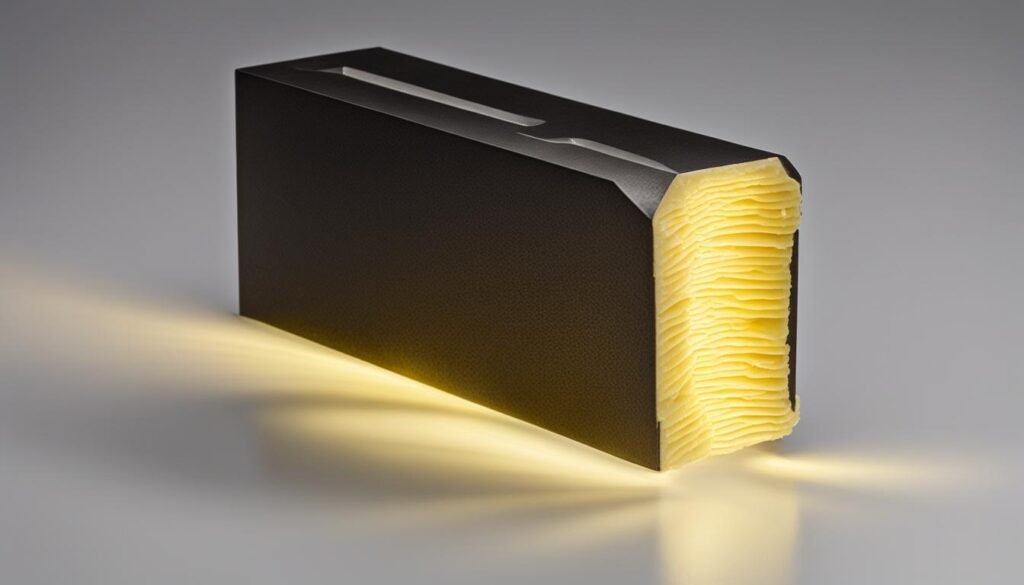

A laser spark plug system involves mounting a separate ignition laser on each cylinder head of the engine. These lasers are powered by an external pump source. The laser spark plug setup offers the advantage of simplicity and direct integration into existing engine designs. However, it requires careful alignment of the laser beams with the combustion chamber for optimal ignition efficiency. Additionally, the design must consider factors such as the required pulse energy, beam focusing optics, and the ability to withstand the harsh conditions in the combustion chamber.

Fiber-Optic Transmission

In contrast to laser spark plugs, fiber-optic transmission setups separate the laser unit from the engine. Ignition pulses are generated by the laser unit and then transmitted to the combustion chambers via optical fibers. This arrangement provides flexibility in terms of laser placement and enables the use of a single laser source for multiple cylinders. Fiber-optic transmission allows for the design of more compact laser ignition systems and offers potential advantages in terms of heat management and system durability. However, it requires careful consideration of factors such as pulse transmission efficiency, optical fiber properties, and the overall system complexity.

Designing laser ignition systems involves finding a balance between factors such as pulse energy, beam quality, alignment tolerances, and system robustness. The goal is to develop compact and reliable systems capable of delivering the required ignition pulses to ignite the combustion process efficiently. Ongoing research and development efforts are focused on improving the performance and durability of laser ignition systems, ultimately paving the way for enhanced combustion technologies.

Experimental Investigation of Laser Ignition

Laser ignition has been the subject of extensive experimental studies to evaluate its effectiveness in combustion processes. These experiments aim to understand the performance and characteristics of laser ignition under various conditions and fuel-air mixtures. Optical diagnostics techniques, such as high-speed imaging and spectroscopy, have been used to observe and analyze the ignition process in combustion chambers.

Combustion chamber studies have provided valuable insights into the development of flame kernels, shock waves, and flame propagation during laser ignition. High-speed Schlieren photography has been particularly useful in visualizing these phenomena. The experimental data obtained from these studies offers critical information for optimizing laser ignition system design and operation.

“Laser ignition experiments have shown remarkable potential in terms of igniting lean mixtures and reducing pollutant emissions.”

Optical diagnostics, such as laser-induced fluorescence (LIF) and emission spectroscopy, have also been employed to investigate the chemical reactions and species evolution during laser ignition. These techniques allow researchers to measure parameters such as the temperature distribution, fuel concentration, and reaction kinetics in the combustion chamber.

These experimental investigations play a crucial role in advancing laser ignition technology by providing insights into its performance, limitations, and applicability in different combustion scenarios. The findings from these studies contribute to the ongoing research and development efforts to optimize laser ignition systems for practical implementation in internal combustion engines.

Comparison of Laser Ignition and Spark Plug Ignition

Laser ignition and spark plug ignition are two different technologies used for igniting combustion processes in internal combustion engines. Both have their advantages and disadvantages, and a direct comparison can provide valuable insights into their performance and suitability for various applications.

Laser ignition offers several advantages over traditional spark plug ignition. It provides a more efficient combustion process, resulting in improved engine efficiencies. Laser ignition is capable of igniting very lean fuel-air mixtures, which can lead to reduced emissions of nitrogen oxides (NOx). The ability to achieve higher effective mean pressures in the combustion chamber can further enhance performance. Additionally, laser ignition allows for the implementation of multi-point ignition, optimizing the combustion process. However, laser ignition systems can be more expensive to implement compared to spark plug ignition.

On the other hand, spark plug ignition is a well-established and widely used technology. It is relatively cost-effective and has been proven to work effectively in a variety of engine applications. Spark plugs are easily replaceable and require less complex infrastructure compared to laser ignition systems. However, spark plug ignition may have limitations in igniting lean fuel-air mixtures and achieving high combustion efficiencies. It may also lead to higher emissions of NOx compared to laser ignition.

“Laser ignition offers a more efficient combustion process and the ability to ignite lean mixtures, while spark plug ignition is a well-established technology with lower implementation costs.”

A direct comparison between laser ignition and spark plug ignition involves evaluating factors such as combustion duration, ignition timing, and emission levels. These comparisons can help determine the most suitable ignition system based on specific requirements and objectives. The choice between laser ignition and spark plug ignition depends on factors such as engine design, emission regulations, and the desired level of efficiency.

Table: Comparison of Laser Ignition and Spark Plug Ignition

| Aspect | Laser Ignition | Spark Plug Ignition |

|---|---|---|

| Combustion Efficiency | High | Lower |

| Emission Levels | Reduced NOx | Potentially higher NOx |

| Cost | Higher | Lower |

| Ignition of Lean Mixtures | Effective | Limitations |

| Infrastructure Complexity | More complex | Less complex |

The table above summarizes the key differences between laser ignition and spark plug ignition in terms of combustion efficiency, emission levels, cost, ability to ignite lean mixtures, and infrastructure complexity. This information can be used as a guide when considering the implementation of either ignition technology in combustion systems.

Challenges and Future of Laser Ignition

While laser ignition shows promising results, there are still challenges that need to be addressed in order to fully realize its potential in combustion processes. One of the main challenges is the cost associated with implementing laser ignition systems compared to traditional spark plug ignition. Laser ignition requires high-power laser systems that can meet the specific requirements of pulse energy and duration, which can be expensive to develop and maintain. Researchers are actively working on developing more cost-effective laser ignition solutions to overcome this challenge.

Another challenge in laser ignition is the stability and durability of the optical window used in the setup. The optical window is a critical component that separates the hot combustion chamber from the laser oscillator. It needs to withstand high temperatures, pressure, and corrosive combustion byproducts without degrading the laser beam quality. Ongoing research focuses on improving window materials, coatings, and designs to enhance their stability and longevity in harsh combustion environments.

Despite these challenges, the future of laser ignition looks promising. Continued research and development efforts are expected to overcome the obstacles and further advance this technology. Some of the key areas for future developments include increasing the efficiency and reliability of laser ignition systems, optimizing laser parameters for different combustion scenarios, and exploring new applications in various engines and industries.

In summary, laser ignition holds great potential for revolutionizing combustion technologies by offering improved efficiencies and reduced emissions. Overcoming the challenges of cost and optical window stability will be crucial for its widespread implementation. As research progresses and technologies evolve, laser ignition is poised to play a significant role in the future of combustion processes.

Conclusion

In conclusion, laser ignition shows immense potential in revolutionizing combustion processes in internal combustion engines. Through experimental studies, it has been established that laser ignition offers advantages such as improved efficiency, reduced pollutant emissions, and the ability to ignite lean mixtures. The optical diagnostics techniques used in these studies have provided valuable insights into the performance and characteristics of laser ignition systems.

Although there are challenges that need to be addressed, including the cost of implementation and the stability of the optical window, the future prospects of laser ignition look promising. Continued research and development efforts can overcome these obstacles and further enhance the technology. With advancements in laser ignition, combustion systems can be optimized to achieve higher efficiencies and lower emissions.

Overall, laser ignition holds great promise for the future. Its ability to ignite lean mixtures and reduce pollutant emissions can significantly contribute to a cleaner and more sustainable combustion process. As researchers continue to innovate and refine laser ignition systems, we can expect to see widespread implementation of this technology in various combustion applications.

FAQ

What is laser ignition?

Laser ignition is a future ignition concept for internal combustion engines that involves generating an igniting plasma using a focused pulsed laser beam.

What are the advantages of laser ignition?

Laser ignition offers benefits such as improved engine efficiencies, reduced pollutant emissions, and the ability to ignite very lean mixtures.

How does laser ignition compare to spark plug ignition?

Laser ignition has the potential for higher efficiency and lower emissions compared to traditional spark plug ignition systems.

How are laser ignition systems designed?

Laser ignition systems can be designed with separate ignition lasers mounted on each cylinder head or by using optical fibers to transmit ignition pulses to the cylinders.

What experimental studies have been conducted on laser ignition?

Experimental studies have been conducted to investigate the effectiveness of laser ignition in combustion processes, using techniques such as Schlieren photography to observe flame development and propagation.

What are the challenges of implementing laser ignition?

Challenges include the cost of implementation compared to spark plug ignition and the stability and durability of the optical window used in laser ignition setups.

What is the future of laser ignition?

Continued research and development efforts can overcome current challenges and pave the way for widespread implementation of laser ignition in combustion systems, revolutionizing combustion technologies.