Contents

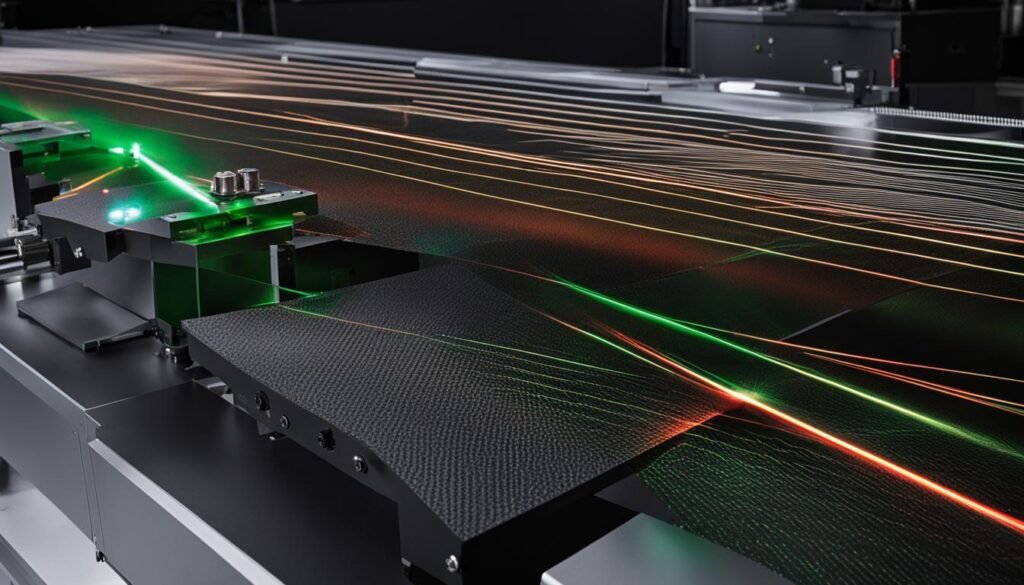

Laser interferometry is a powerful measurement technique that offers unparalleled precision in surface examination. It combines the advantages of traditional interferometry and confocal microscopy, making it a valuable tool in various industries such as microelectronics and precision optics. By using a broadband light source and a Michelson interferometer setup, laser interferometry allows for high-resolution imaging and the measurement of transparent and reflective surfaces. In this comprehensive guide, we will delve into the principles, setup, applications, and potential future directions of laser interferometry, highlighting its vital role in pushing the boundaries of surface metrology.

Key Takeaways:

- Laser interferometry is a powerful measurement technique for examining surfaces with unparalleled precision.

- It combines the advantages of traditional interferometry and confocal microscopy.

- By using a broadband light source and a Michelson interferometer setup, laser interferometry allows for high-resolution imaging and measurement of transparent and reflective surfaces.

- It finds application in various industries such as microelectronics and precision optics.

- Laser interferometry plays a vital role in pushing the boundaries of surface metrology.

Principles of Laser Interferometry

https://www.youtube.com/watch?v=Ftr119HvgIM

Laser interferometry is a measurement technique that operates on the principles of interference, utilizing a setup known as a interferometer. It is commonly used in various industries, including microelectronics and precision optics, due to its unparalleled precision in surface examination. By combining the advantages of traditional interferometry and confocal microscopy, laser interferometry offers high-resolution imaging and the ability to measure transparent and reflective surfaces.

The setup of a laser interferometer involves a Michelson interferometer, which splits a beam of light into two paths using beam splitters or mirrors. These split light waves then recombine, creating interference patterns that can be analyzed to extract surface information. The key parameter in laser interferometry is the optical path difference (OPD) – the variance in distance traveled by light waves in different arms of the interferometer.

The interference patterns formed by laser interferometry can be translated into three-dimensional surface profiles, enabling the measurement of surface roughness and other topographical features. This technique has a wide range of applications, from precision manufacturing to biomedical research, where accuracy and precision are essential.

Overall, laser interferometry is a powerful measurement technique that relies on interference patterns and optical path differences to extract detailed surface information. It has opened up new possibilities in the field of surface metrology and continues to push the boundaries of precision measurements in various industries.

Types of Interferometers

Laser interferometry utilizes various types of interferometers to measure and analyze interference patterns. Each type has unique characteristics and applications in different fields. Here are the main types of interferometers used in laser interferometry:

Mach-Zehnder Interferometer

The Mach-Zehnder interferometer is a split beam design that utilizes two beam splitters and two mirrors. It is commonly used in telecommunications and optical fiber networks. By splitting the light beam into two paths and recombining them, the Mach-Zehnder interferometer can measure parameters such as phase modulation and optical loss in optical communication systems.

Michelson Interferometer

The Michelson interferometer is a classic design that consists of a beam splitter and two mirrors. It is versatile and finds applications in spectroscopy, metrology, and gravitational wave detection. Michelson interferometers are used for measuring small displacements, velocity, and refractive index changes in materials. They are also used in the Michelson-Morley experiment to detect the motion of the Earth through the luminiferous aether.

Fizeau Interferometer

The Fizeau interferometer is used to measure surface irregularities and shapes of objects in optics manufacturing and quality control. It involves splitting a beam of light and reflecting it off a test surface and a reference surface. The interference pattern generated provides information about the surface shape and the presence of defects or imperfections.

Twyman-Green Interferometer

The Twyman-Green interferometer is commonly used in precision manufacturing to measure the shape of surfaces and the refractive index of transparent materials. It consists of a beam splitter, two mirrors, and a camera or detector. By analyzing the interference pattern produced when light waves reflected from the test surface and the reference surface are recombined, the Twyman-Green interferometer can provide accurate measurements of surface flatness and refractive index variations.

Table:

| Interferometer Type | Applications |

|---|---|

| Mach-Zehnder Interferometer | Telecommunications, optical fiber networks |

| Michelson Interferometer | Spectroscopy, metrology, gravitational wave detection |

| Fizeau Interferometer | Optics manufacturing, quality control |

| Twyman-Green Interferometer | Precision manufacturing, refractive index measurements |

These types of interferometers are at the core of laser interferometry, enabling precise measurements and analysis of interference patterns. By harnessing the principles of interference, laser interferometry continues to advance various fields, from telecommunications to manufacturing to scientific research.

How Laser Interferometry Works

Laser interferometry is a fascinating technique that harnesses the principles of interference to extract valuable information about surfaces. It involves the superimposition and interaction of two or more light waves, creating an interference pattern that can be analyzed to measure various parameters. At its core, laser interferometry relies on two key concepts: interference and optical path difference.

Interference occurs when light waves interact and either reinforce or cancel each other out. This phenomenon can be observed in everyday life, such as when light reflects off a thin film of oil on water, producing vibrant colors. In laser interferometry, the interference pattern is created by splitting a beam of light and recombining the resulting waves. This pattern contains valuable information about the surfaces being measured.

The optical path difference (OPD) is another crucial aspect of laser interferometry. It refers to the variance in distance traveled by light waves in different arms of the interferometer. By precisely measuring the OPD, laser interferometers can determine parameters such as surface flatness, thickness, and refractive index. Different interferometer configurations, such as the Michelson and Mach-Zehnder setups, are used to produce interference patterns and measure specific parameters.

Interferometer Configurations

There are several interferometer configurations used in laser interferometry, each with its own advantages and applications:

- The Michelson interferometer is a classic design that splits a beam of light into two paths using a beam splitter. It is versatile and finds applications in spectroscopy, metrology, and gravitational wave detection.

- The Mach-Zehnder interferometer utilizes a split beam design with multiple beam splitters. It is commonly used in telecommunications and optical fiber networks.

These configurations, along with others like the Fizeau interferometer and Twyman-Green interferometer, offer various ways to measure and analyze interference patterns. By understanding how these interferometer configurations work, we can gain a deeper appreciation for the versatility and potential of laser interferometry.

Table: Interferometer Configurations and Applications

| Interferometer Configuration | Applications |

|---|---|

| Michelson interferometer |

|

| Mach-Zehnder interferometer |

|

| Fizeau interferometer |

|

| Twyman-Green interferometer |

|

Applications of Laser Interferometry

Laser interferometry, with its precision measurement capabilities, finds a wide range of applications across various industries. Let’s explore some of the key fields where laser interferometry plays a vital role.

Astronomy

In astronomy, laser interferometers enhance the resolution of telescopes, allowing scientists to study celestial objects in finer detail. With the help of interferometers, astronomers can measure the angular diameter of stars, observe the motion of galaxies, and even capture images of black holes. The groundbreaking image of a black hole captured by the Event Horizon Telescope was made possible through the use of laser interferometry.

Telecommunications

In the field of telecommunications, laser interferometry is used to measure the reflectivity of optical fiber connectors and couplers. By accurately assessing the quality and performance of these components, laser interferometers ensure reliable and efficient data transmission in modern communication networks.

Precision Manufacturing

Laser interferometry is a crucial tool for precision manufacturing industries. It enables precise measurements of parameters such as thickness, flatness, and surface quality of optical components. By ensuring the accuracy of these measurements, laser interferometers contribute to the production of high-quality optical products used in various applications.

Biomedical Research

In biomedical research, laser interferometry is utilized to measure the thickness of thin films on cells and tissues. It also helps in studying the optical properties of biological samples, providing valuable insights for understanding cellular structures and processes. Laser interferometry plays a significant role in advancing biomedical research and contributing to breakthrough discoveries in the field.

Laser interferometry’s applications extend beyond these fields, finding use in many other industries where precise measurements and surface examinations are critical. Its versatility and accuracy make it an indispensable tool for researchers, engineers, and scientists pushing the boundaries of measurement and analysis.

Laser Interferometry in Astronomy

Laser interferometry has had a profound impact on the field of astronomy, revolutionizing our ability to study celestial objects with unprecedented detail. One of the key applications of laser interferometry in astronomy is resolution enhancement. By combining the signals from multiple telescopes, interferometers can effectively increase the resolving power of telescopic systems. This allows astronomers to observe objects with higher clarity and precision, revealing intricate details that would otherwise be obscured.

An exceptional example of laser interferometry’s contribution to astronomy is the imaging of black holes. Using a global network of radio telescopes known as the Event Horizon Telescope, scientists were able to capture the first-ever direct image of a black hole in 2019. This groundbreaking achievement was made possible by the synchronization of multiple telescopes using laser interferometry, enabling the formation of a virtual telescope with a diameter roughly equivalent to the Earth’s diameter. The resulting image provided valuable insights into the nature and behavior of black holes.

In addition to black hole imaging, laser interferometry also plays a vital role in the analysis of exoplanets. By measuring the slight variations in a star’s position caused by the gravitational pull of an orbiting exoplanet, interferometers can detect the presence of these distant worlds. This technique, known as astrometry, provides valuable data on the masses, orbits, and other properties of exoplanets, contributing to our understanding of planetary formation and the potential for habitability beyond our solar system.

Advancing our understanding of the universe

The application of laser interferometry in astronomy has opened up new avenues of exploration and discovery. By enhancing the resolution of telescopes, interferometers enable scientists to study celestial objects in unprecedented detail, unveiling the mysteries of the cosmos. From imaging black holes to analyzing exoplanets, laser interferometry continues to push the boundaries of our knowledge and fuel our curiosity about the universe.

Laser Interferometry in Metrology

Laser interferometry plays a crucial role in metrology, the science of measurement. It enables high-precision measurements of various parameters, making it an invaluable tool in industries that require accurate and reliable data. Whether it’s dimensional metrology or surface metrology, laser interferometry provides the necessary precision to meet strict standards and ensure quality.

One of the key applications of laser interferometry in metrology is calibration. Laser interferometers are used to calibrate equipment and instruments, ensuring their accuracy and reliability over time. By comparing the measurements of the instrument under test with a known reference, laser interferometry allows for precise calibration, minimizing errors and maintaining measurement integrity.

In dimensional metrology, laser interferometry is used to measure length, thickness, and other dimensional parameters. With its high-resolution imaging capabilities, laser interferometry enables the accurate characterization of surfaces and the determination of critical dimensions. This is especially important in industries such as manufacturing, aerospace, and automotive, where precise measurements are essential for quality control and product performance.

Surface metrology is another area where laser interferometry excels. It allows for the measurement of surface roughness, waviness, and other topographical features with exceptional precision. Laser interferometers can capture interference patterns and extract valuable data about the surface characteristics, providing insights into the quality and performance of a wide range of materials and components.

| Application | Description |

|---|---|

| Calibration | Laser interferometry is used to calibrate equipment and instruments, ensuring their accuracy and reliability over time. |

| Dimensional Metrology | Laser interferometry enables the precise measurement of length, thickness, and other dimensional parameters, critical for industries such as manufacturing and aerospace. |

| Surface Metrology | Laser interferometry allows for the accurate measurement of surface roughness, waviness, and other topographical features, providing insights into material quality and performance. |

Quote: “Laser interferometry has revolutionized metrology, enabling high-precision measurements and calibration processes that are essential for industries that demand accuracy and reliability.” – Expert in Metrology

In conclusion, laser interferometry is a vital tool in metrology, allowing for high-precision measurements and calibration processes. Its applications in dimensional metrology and surface metrology provide accurate insights into critical parameters, ensuring quality control and meeting industry standards. With its ability to capture interference patterns and extract valuable information, laser interferometry continues to push the boundaries of precision measurement, contributing to advancements in various fields.

Conclusion

In conclusion, laser interferometry is a powerful and versatile measurement technique that has revolutionized surface examination in various industries. By combining the principles of interference and the capabilities of laser technology, laser interferometry offers unparalleled precision in measuring surface roughness, topographical features, and other parameters.

With its wide range of applications, laser interferometry has proven to be invaluable in fields such as astronomy, telecommunications, precision manufacturing, and biomedical research. Its ability to enhance the resolution of telescopes has allowed astronomers to study celestial objects with unprecedented detail, while in telecommunications, it plays a critical role in measuring the reflectivity of optical fibers.

In metrology, laser interferometry enables high-precision measurements and calibration processes, ensuring the accuracy and reliability of instruments. Its use in dimensional and surface metrology has significantly advanced the field, supporting engineering, manufacturing, and scientific research.

As technology continues to advance, we can expect further groundbreaking discoveries and advancements in laser interferometry. With its unique capabilities and continued research, laser interferometry will continue to push the boundaries of surface metrology and redefine our understanding of the world around us.

FAQ

What is laser interferometry?

Laser interferometry is a powerful measurement technique that offers unparalleled precision in surface examination by utilizing interference patterns created by combining light waves of different wavelengths.

How does laser interferometry work?

Laser interferometry works by splitting a beam of light into two or more paths using beam splitters or mirrors and then recombining them to create an interference pattern. This pattern can be analyzed to extract parameters such as optical paths, wavelength, refractive index, and surface flatness.

What are the types of interferometers used in laser interferometry?

The types of interferometers used in laser interferometry include the Mach-Zehnder interferometer, Michelson interferometer, Fizeau interferometer, and Twyman-Green interferometer.

What are the applications of laser interferometry?

Laser interferometry has a wide range of applications including in astronomy, telecommunications, precision manufacturing, and biomedical research.

How is laser interferometry used in astronomy?

Laser interferometry enhances the resolution of telescopes, allowing for detailed study of celestial objects. It has been used to capture the first-ever image of a black hole and study exoplanets and their atmospheres.