Source: Accurl

Understanding Laser Machining: Techniques and Applications

Introduction to Laser Machining

Laser machining, also known as laser beam machining, is a modern method of material processing that uses a focused laser beam to remove material from a workpiece. This subtractive technique is widely used in various industries due to its precision and efficiency. Laser machining encompasses several specific processes, each suited to different applications.

Key Techniques in Laser Machining

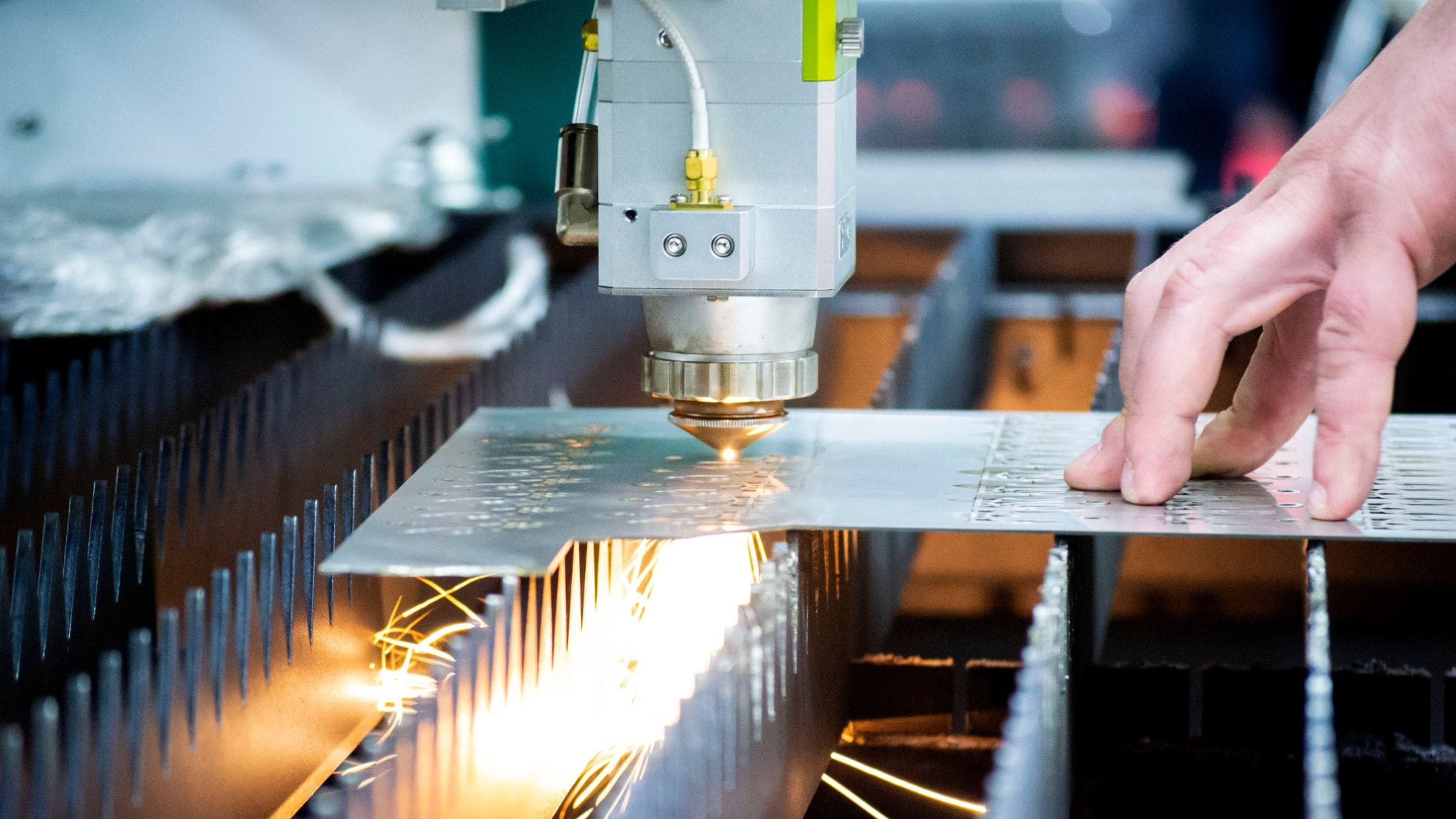

Laser Cutting

Laser cutting is a technique used to slice through materials such as metals, ceramics, and glasses with high precision. The laser beam melts, burns, or vaporizes the material, creating clean edges and intricate designs. This method is favored for its speed and accuracy, making it a staple in industries like automotive and aerospace manufacturing.

Laser Drilling

Laser drilling involves creating holes in a material using a concentrated laser beam. This method is particularly useful for producing small, precise holes in materials that are difficult to drill using conventional methods. Laser trepanning, a related technique, involves cutting holes by tracing a circular path with the laser.

Laser Milling

Laser milling is a process that removes material layer by layer, allowing for the creation of complex 3D structures. This method is ideal for both large surfaces and fine, intricate designs. It is commonly used in the production of machine parts and in the electronics industry for microfabrication.

Laser Scribing

Laser scribing involves creating elongated faults, such as grooves or microscopic cracks, in a material. This technique is often used in the semiconductor industry to prepare wafers for further processing. It is also applied to materials like glass and ceramics for precise cutting and shaping.

Laser Micromachining

Laser micromachining refers to the machining of very small parts or the creation of fine structures on larger parts. This encompasses various operations, including cutting, drilling, and milling, and is crucial in industries requiring precision at microscopic scales.

Advantages of Laser Machining

Laser machining offers several advantages over traditional machining methods:

- Non-contact processing reduces tool wear and extends tool life.

- High precision and accuracy in material removal.

- Rapid processing speeds, enhancing productivity.

- Compatibility with automation technologies, facilitating integration with CAD and robotics.

Applications of Laser Machining

Laser machining is versatile and applicable to a wide range of materials, including metals, ceramics, glasses, polymers, textiles, leather, paper, and wood. Its applications span numerous industries, such as:

- Automotive manufacturing for precise component production.

- Aerospace for lightweight and durable parts.

- Medical instruments for intricate and sterile equipment.

- Electronics for microfabrication of circuit boards and components.

As laser machining technology continues to advance, it plays an increasingly vital role in modern manufacturing, offering solutions that were previously unattainable with conventional methods.

Source: Accurl

Feel free to comment your thoughts.