Contents

- 1 Laser Marking Applications

- 2 Laser Engraving in the Jewelry Sector

- 3 Enhancing Precision and Efficiency with Desktop Laser Marking Machines

- 4 Conclusion

- 5 FAQ

- 5.1 What is laser marking?

- 5.2 Why is laser marking preferred in industrial processes?

- 5.3 What types of laser machines can be used for laser marking?

- 5.4 Are laser markings permanent?

- 5.5 In which industries is laser marking widely used?

- 5.6 What is laser engraving used for in the jewelry sector?

- 5.7 What are desktop laser marking machines used for?

- 5.8 What are the benefits of laser marking?

- 6 Source Links

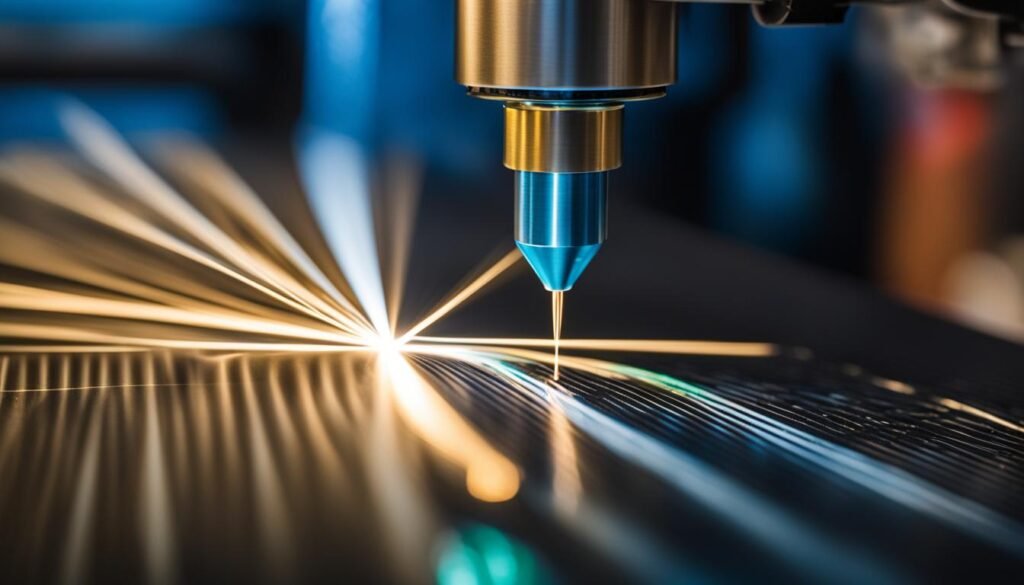

Laser marking is a process used by manufacturers and designers to make a permanent impression on various materials such as metal, plastic, film, and laminates. It offers precision and efficiency, making it a preferred choice for industrial processes. Laser machines are more effective than traditional hand tools, offering faster processing speeds, higher quality results, and cost-effectiveness. Different types of laser machines, such as fiber, CO2, crystal, and pulse lasers, can be used based on the materials and time frame involved. Laser markings are permanent, resistant to acids and heat, and can mark diverse shapes without loss of quality.

Key Takeaways:

- Laser marking is a process used for permanent impressions on various materials.

- Laser machines offer faster processing speeds and higher quality results compared to traditional hand tools.

- Different types of laser machines can be used based on materials and time frames.

- Laser markings are permanent, resistant to acids and heat, and maintain quality on diverse shapes.

- Laser marking is cost-effective, making it a preferred choice for industrial processes.

Laser Marking Applications

Laser technology has revolutionized various industries with its versatility and precision. The applications of laser marking are vast and diverse, making it an essential tool for industrial processes, jewelry making, medical devices, aerospace, and electronics manufacturing.

Industrial Laser Marking

In the industrial manufacturing sector, laser marking plays a crucial role in ensuring product traceability and regulatory compliance. It is used to mark permanent identification codes, serial numbers, and barcodes on products. This allows manufacturers to track products throughout their lifecycle, ensuring quality control and facilitating efficient inventory management. Laser marking provides a permanent and tamper-proof marking solution that withstands harsh environmental conditions and resists fading, offering long-lasting product identification.

Laser Marking Solutions

In addition to industrial applications, laser marking solutions find extensive use in other industries as well. In the jewelry sector, laser marking machines are used to engrave intricate designs on precious metals and personalize jewelry with custom designs. The medical device industry utilizes laser marking to engrave markings on surgical instruments and implants, ensuring accurate identification and traceability during surgical procedures. Aerospace manufacturers rely on laser marking to mark components with identification codes, ensuring efficient assembly and maintenance. In the electronics manufacturing industry, laser marking is used to mark circuit boards and electronic components, providing traceability and protection against counterfeiting.

Overall, laser marking applications offer a wide range of benefits, including permanent and precise markings, fast processing speeds, and the ability to mark various materials without compromising quality. The use of laser technology allows industries to enhance their productivity, efficiency, and product quality, making it an indispensable tool for numerous applications.

| Laser Marking Applications | Industries |

|---|---|

| Permanent identification codes, serial numbers, and barcodes | Industrial manufacturing |

| Intricate designs and personalization on precious metals | Jewelry making |

| Engraving markings on surgical instruments and implants | Medical devices |

| Marking components with identification codes | Aerospace |

| Marking circuit boards and electronic components | Electronics manufacturing |

Laser Engraving in the Jewelry Sector

Laser engraving has revolutionized the jewelry sector with its unparalleled precision and quality results. Utilizing advanced laser marking machines, jewelers can engrave intricate designs, personalized texts, logos, barcodes, and even photos on a wide range of materials including gold, silver, platinum, copper, and glass.

The laser engraving process involves using a high-powered laser beam to remove surface material, leaving behind a permanent engraved impression. This method offers a high level of finish, does not damage the jewelry, and ensures indelible markings that resist the effects of time, chemical agents, and atmospheric conditions.

One of the key advantages of laser engraving in the jewelry sector is its ability to provide a guarantee certificate when engraving diamonds. By marking specific identification codes, laser engraving serves as a certification of origin and value, giving customers peace of mind when purchasing precious stones.

“Laser engraving has completely transformed the way we create personal and intricate designs on jewelry. Its precision and versatility allow us to offer unique pieces to our customers,” says Lisa Miller, a renowned jewelry designer.

Advantages of Laser Engraving in Jewelry Making

- Precision: Laser engraving offers unmatched precision, allowing jewelers to create intricate designs with fine details that would be challenging to achieve through traditional methods.

- Personalization: With laser engraving, jewelers can offer personalized jewelry by engraving names, initials, special dates, or even fingerprints, creating unique pieces that hold sentimental value.

- Efficiency: Laser engraving machines can quickly and efficiently engrave multiple pieces of jewelry, enhancing productivity and reducing production time.

- Versatility: Laser engraving can be used on various materials, accommodating a wide range of designs and styles. It allows jewelers to experiment with different textures, patterns, and shapes.

| Laser Engraving | Traditional Engraving | |

|---|---|---|

| Precision | High precision, intricate details | Lower precision, limited details |

| Speed | Fast and efficient | Time-consuming |

| Flexibility | Accommodates various designs | Restricted by manual skills |

| Adaptability | Works on different materials | Material-specific techniques |

Enhancing Precision and Efficiency with Desktop Laser Marking Machines

Desktop laser marking machines have emerged as a game-changer in various industries, offering unmatched precision, versatility, and efficiency. Combining cutting-edge laser marking technology with compact design, these machines deliver exceptional results for a wide range of applications.

In the industrial manufacturing sector, desktop laser marking machines play a crucial role in product traceability and regulatory compliance. They can effortlessly mark permanent identification codes, serial numbers, and barcodes on various materials, including metals, plastics, and ceramics. This ensures seamless tracking and accountability throughout the manufacturing process.

When it comes to the jewelry sector, desktop laser marking machines have revolutionized the art of engraving intricate designs on precious metals. Whether it’s a custom design or a personalized message, these machines offer unparalleled precision and quality. Jewelry makers can now easily add value to their creations and provide customers with unique and personalized pieces.

| Industry | Applications |

|---|---|

| Industrial Manufacturing | Product identification codes, serial numbers, barcodes |

| Jewelry | Intricate designs, personalized messages |

| Medical Devices | Surgical instruments, implants marking |

| Aerospace | Identification codes on components |

| Electronics Manufacturing | Circuit boards, electronic components marking |

Desktop laser marking machines are also widely utilized in the medical device industry. Surgeons rely on them to mark surgical instruments and implants, ensuring accurate tracking and compatibility during complex procedures. The durability and precision of laser marking make it an ideal choice for medical devices that undergo sterilization processes.

The aerospace industry benefits from the precision and durability of desktop laser marking machines for marking identification codes on critical components. These markings play a crucial role in maintenance, repair, and overall safety records. Laser marking ensures clear and permanent identification, even under extreme environmental conditions.

In the fast-paced world of electronics manufacturing, desktop laser marking machines provide a reliable solution for marking circuit boards and electronic components. This ensures traceability, quality control, and anti-counterfeiting measures. Laser markings can be easily customized to meet specific requirements, enabling electronics manufacturers to enhance their product authenticity.

With their ability to deliver precision, versatility, and efficiency, desktop laser marking machines have become an essential tool across industries. Whether for industrial manufacturing, jewelry making, medical devices, aerospace, or electronics manufacturing, these machines offer unmatched results and revolutionize the way products are marked and identified.

Conclusion

Laser marking solutions, powered by advanced laser technology, offer unmatched precision and efficiency across various industries. With their cost-effective and time-saving capabilities, laser marking machines have revolutionized manufacturing and production processes.

By employing high-powered laser beams, these machines provide faster processing speeds, ensuring quick turnaround times for high volume marking. The permanent markings created by laser technology are resistant to acids and heat, making them durable and reliable for a wide range of applications.

Whether it’s marking identification codes, serial numbers, barcodes, intricate designs, or personalized messages, laser marking solutions consistently deliver high-quality results. Industries such as industrial manufacturing, jewelry making, medical devices, aerospace, and electronics manufacturing rely on laser technology for its unmatched precision and efficiency.

As laser marking continues to evolve and improve, it remains an essential tool for enhancing the quality and productivity of various industries. With its ability to mark diverse shapes without compromising on quality, laser marking solutions are paving the way for continued advancements in manufacturing and production processes.

FAQ

What is laser marking?

Laser marking is a process used by manufacturers and designers to make a permanent impression on various materials such as metal, plastic, film, and laminates.

Why is laser marking preferred in industrial processes?

Laser machines offer faster processing speeds, higher quality results, and cost-effectiveness compared to traditional hand tools.

What types of laser machines can be used for laser marking?

Different types of laser machines, such as fiber, CO2, crystal, and pulse lasers, can be used based on the materials and time frame involved.

Are laser markings permanent?

Yes, laser markings are permanent, resistant to acids and heat, and can mark diverse shapes without loss of quality.

In which industries is laser marking widely used?

Laser marking is widely used in industries such as manufacturing, jewelry making, medical devices, aerospace, and electronics.

What is laser engraving used for in the jewelry sector?

Laser engraving is used in the jewelry sector for engraving personalized texts, decorations, designs, logos, and barcodes on materials such as gold, silver, platinum, copper, and glass.

What are desktop laser marking machines used for?

Desktop laser marking machines are used for marking permanent identification codes, serial numbers, barcodes, intricate designs, and personalized messages on various materials in industries such as manufacturing, jewelry making, medical devices, aerospace, and electronics.

What are the benefits of laser marking?

Laser marking offers precision, efficiency, permanent markings that resist acids and heat, and the ability to mark diverse shapes without loss of quality.