Contents

- 1 Industrial Laser Micromachining Tools

- 2 Laser Micromachining Services

- 3 Laser Micromachining Applications

- 4 Laser Micromachining Solutions from 3D-Micromac

- 5 Laser Micromachining Platforms from GF Machining Solutions

- 6 Conclusion

- 7 FAQ

- 7.1 What is laser micromachining?

- 7.2 What kind of materials can be processed with laser micromachining?

- 7.3 What industries can benefit from laser micromachining?

- 7.4 What laser micromachining services do you offer?

- 7.5 What are the advantages of using laser micromachining tools?

- 7.6 What types of laser micromachining tools do you provide?

- 7.7 Can you provide custom laser micromachining solutions?

- 7.8 What is the role of laser micromachining in the aerospace industry?

- 7.9 How does laser micromachining benefit medical device manufacturers?

- 7.10 How is laser micromachining used in the automotive industry?

- 7.11 Why is laser micromachining important in the watch industry?

- 8 Source Links

At [Company Name], we specialize in providing advanced laser micromachining solutions for a wide range of industries. Our expertise lies in precision laser machining, laser ablation, and high precision micromachining, offering both products and contract services to meet the unique needs of our customers.

Our comprehensive range of laser micromachining products includes industrial-grade tools and research systems. These include the efficient and robust ‘C Series,’ the versatile and customizable ‘E Series,’ the advanced and innovative ‘G Series,’ the powerful and precise ‘J Series,’ and more. With features such as granite beds and gantries, our tools are designed to provide unmatched precision and positional accuracy.

In addition to our products, we offer contract laser micromachining services in our dedicated laboratories. Our experienced engineers utilize state-of-the-art laser technology to perform processes such as milling, drilling, cutting, engraving, and welding on a wide variety of materials. From small-scale feasibility studies to large-volume production, we have the expertise to deliver top-quality results.

Key Takeaways:

- Laser micromachining offers high precision and positional accuracy for various applications.

- We provide advanced laser micromachining tools and research systems tailored to specific needs.

- Our contract laser micromachining services cover a wide range of processes and material types.

- Laser micromachining finds applications in industries such as aerospace, medical, automotive, and watchmaking.

- At [Company Name], we offer innovative solutions and reliable support throughout the product life cycle.

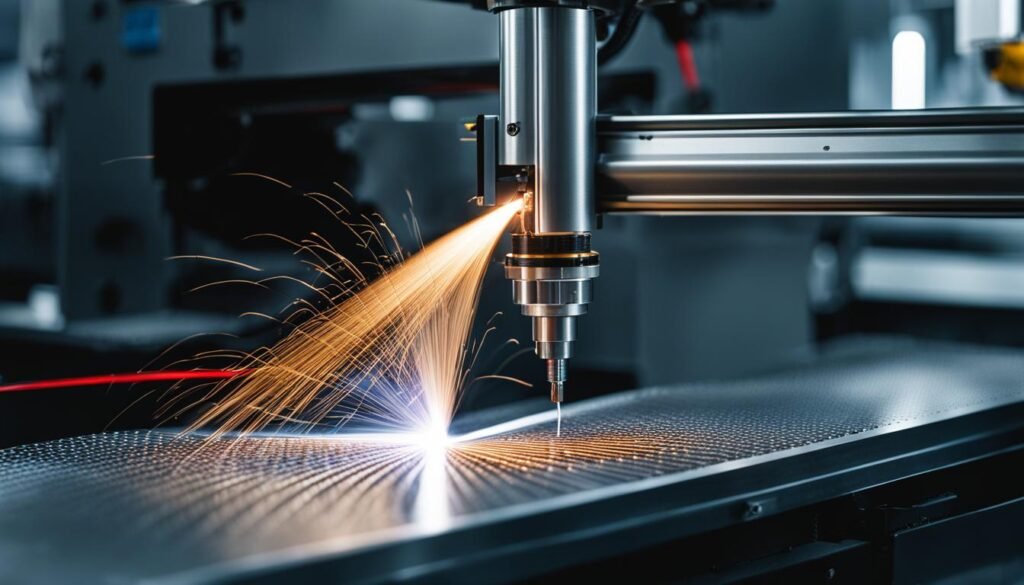

Industrial Laser Micromachining Tools

When it comes to precision laser micromachining, we offer a comprehensive range of industrial-grade tools that cater to the diverse needs of manufacturers. Our laser micromachining tools are designed to deliver high performance and exceptional precision, enabling manufacturers to achieve their desired outcomes with ease.

Product Range

Our range of laser micromachining products includes:

- ‘C Series’: An efficient and robust tool designed for high-throughput production.

- ‘E Series’: A versatile and customizable tool ideal for research and development.

- ‘G Series’: An advanced and innovative tool for processing a wide range of materials.

- ‘J Series’: A powerful and precise tool for challenging process applications.

Each tool in our range is equipped with advanced features such as granite beds and gantries, ensuring high precision and positional accuracy. Our tools are renowned for their reliability and durability, making them the ideal choice for demanding industrial applications.

Specifications

Here are some key specifications of our laser micromachining tools:

| Tool | Laser Power | Motion Control | Toolpath Control |

|---|---|---|---|

| ‘C Series’ | Up to 100W | XYZ Control | CIMITA Software |

| ‘E Series’ | Up to 50W | XYZ Control | CIMITA Software |

| ‘G Series’ | Up to 200W | XYZ Control | CIMITA Software |

| ‘J Series’ | Up to 500W | XYZ Control | CIMITA Software |

With our powerful CIMITA software, users have full control over both laser and motion control parameters, allowing for the creation of sophisticated toolpaths tailored to specific machining requirements.

Laser Micromachining Services

In addition to our range of laser micromachining products, we also offer contract laser micromachining services. Our dedicated contract micromachining laboratories are equipped with the latest laser micromachining tools operated by experienced engineers. We provide a comprehensive range of services, including laser milling, drilling, cutting, engraving, welding, and more.

Our team of experts has the knowledge and expertise to work with a wide variety of materials, from metals to polymers. Whether you require small-scale feasibility studies or large-volume production, we can cater to your specific needs. Our laser micromachining services are known for their exceptional precision and quality, ensuring that your components are machined to the highest standards.

By outsourcing your laser micromachining needs to us, you can benefit from our state-of-the-art facilities and specialized equipment, without the need for significant investment in machinery. We offer flexible contract terms and competitive pricing to suit your budget and project requirements. Trust us to deliver efficient and reliable laser micromachining solutions tailored to your unique specifications.

| Service | Description | Advantages |

|---|---|---|

| Laser Milling | Precision material removal using laser technology. | High accuracy, fine detailing, and complex shapes. |

| Laser Drilling | Precise hole formation in various materials. | Fast, accurate, and repeatable drilling process. |

| Laser Cutting | Laser-based cutting of intricate patterns and shapes. | High-quality cuts with minimal material waste. |

| Laser Engraving | Precision surface marking and engraving. | Detailed designs, permanent markings. |

Our laser micromachining services offer a reliable and cost-effective solution for your precision manufacturing needs. Contact us today to discuss your project requirements and benefit from our expertise in laser micromachining.

Laser Micromachining Applications

Laser micromachining has proven to be a versatile technology with a wide range of applications across various industries. Its precise cutting, drilling, and engraving capabilities make it ideal for producing small, high-precision parts that are essential in aerospace, medical, automotive, and watch sectors. Let’s explore some of the specific applications where laser micromachining plays a crucial role.

Aerospace

In the aerospace industry, laser micromachining solutions are used to reduce production costs while ensuring the drilling and shaping of mid-sized parts. With the ability to achieve high precision and positional accuracy, laser micromachining enables the creation of intricate components necessary for aircraft engines, structural elements, and other critical aerospace systems.

Medical

Medical device manufacturers rely on the precision and miniaturization capabilities of laser micromachining to meet stringent regulatory requirements. Laser micromachining allows for the fabrication of intricate parts with tight tolerances, ensuring the production of high-quality medical devices. It is used in applications such as manufacturing stents, catheters, implants, and other critical medical components.

Automotive

In the automotive industry, laser micromachining is utilized to produce microholes in fuel injectors, leading to improved performance and meeting emissions requirements. Laser micromachining offers the ability to create tiny, precise features with high repeatability, ensuring the reliability and efficiency of automotive systems.

Watches

The watch industry heavily relies on laser micromachining to create extremely small and tight-tolerance components. Laser micromachining enables the production of intricate watch parts, such as gears, springs, and dials, with exceptional precision. This technology plays a crucial role in meeting the demands of luxury watchmaking, where precision and aesthetics are paramount.

As laser micromachining continues to evolve, its applications are expanding into new areas. Industries such as electronics, telecommunications, and energy are also finding innovative uses for laser micromachining technology, further highlighting its versatility and potential.

Laser Micromachining Solutions from 3D-Micromac

3D-Micromac is a leading provider of laser micromachining solutions, offering a range of products and services tailored to meet the specific needs of various industries. With over twenty years of expertise, they are reliable partners in technology and process development, providing innovative solutions that ensure high precision and efficiency.

One of their key strengths lies in their excimer laser systems, which are widely recognized for their exceptional performance in precision micromachining. These systems utilize short-wavelength UV lasers, delivering highly accurate processing results with minimal heat affected zones. The excimer laser systems from 3D-Micromac are ideal for cutting, drilling, and structuring a wide range of materials, including metals, ceramics, glass, and polymers.

Another area of expertise for 3D-Micromac is ultra-short pulse laser systems. These systems generate ultra-short pulses of laser energy, allowing for precise material removal without causing thermal damage. Ultra-short pulse laser systems are particularly effective in micromachining applications that require high surface quality and intricate geometries. They are widely used in the semiconductor, electronics, and medical industries.

Furthermore, 3D-Micromac specializes in roll-to-roll laser machining of flexible substrates. This technology enables continuous processing of flexible materials, such as foils and films, with high throughput and accuracy. Roll-to-roll laser machining is widely employed in the production of flexible electronics, solar cells, and displays, where precision and speed are of utmost importance.

| Laser Micromachining Solutions | Description |

|---|---|

| Excimer Laser Systems | Utilizes short-wavelength UV lasers for precise cutting, drilling, and structuring of various materials. |

| Ultra-Short Pulse Laser Systems | Generates ultra-short pulses of laser energy for high-precision micromachining without thermal damage. |

| Roll-to-Roll Laser Machining | Enables continuous processing of flexible substrates with high throughput and accuracy for various applications. |

3D-Micromac supports customers throughout the entire product life cycle, from process development to commissioning and servicing. Their comprehensive range of laser micromachining solutions ensures that manufacturers have access to cutting-edge technology and expertise needed to meet the demands of modern micromachining applications.

“The excimer laser systems from 3D-Micromac offer exceptional performance in precision micromachining, delivering highly accurate results with minimal heat affected zones.”

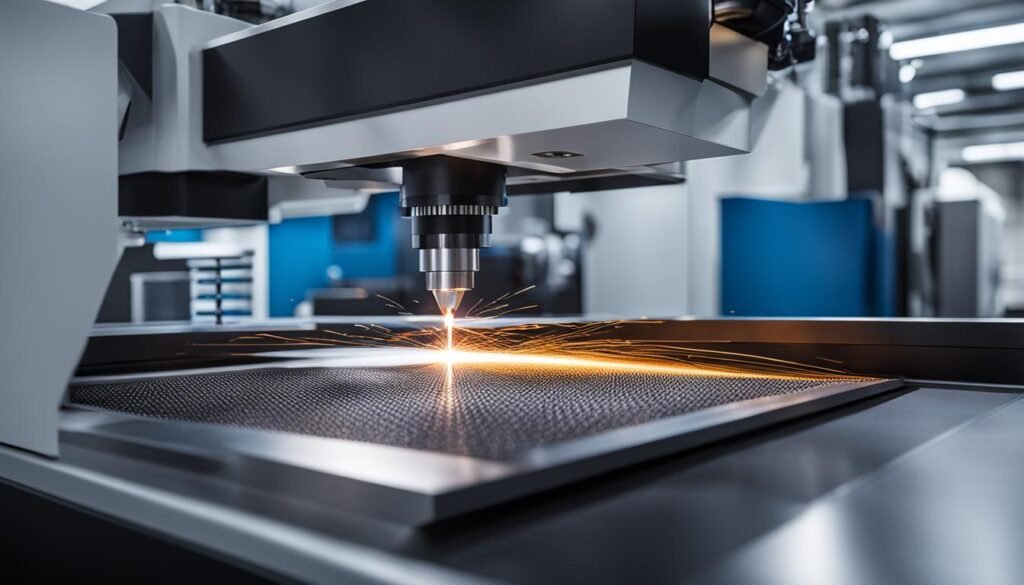

Laser Micromachining Platforms from GF Machining Solutions

GF Machining Solutions offers a comprehensive line of laser micromachining platforms optimized to meet the increasing demand for high-precision parts. These platforms are designed to deliver exceptional performance and accuracy, combined with advanced features to enhance the efficiency of micromachining processes in various industries such as aerospace, medical, automotive, and watches.

One of the standout platforms from GF Machining Solutions is the ML-5. This platform is known for its ability to produce excellent edge and surface quality, as well as straight sidewalls. It provides a reliable and precise solution for micromachining applications that require intricate details and tight tolerances. With the ML-5, manufacturers can achieve superior results in producing small, high-precision parts.

The ML-10 is another laser micromachining platform offered by GF Machining Solutions. It maximizes workspace and is ideal for aerospace applications where larger parts need to be processed with high precision. The ML-10 provides manufacturers with the flexibility to handle complex geometries and meet the stringent requirements of the aerospace industry.

For medical applications, GF Machining Solutions offers the MLTC platform. This platform simplifies complex machining processes, particularly in cutting tubes for medical devices. The MLTC is designed to ensure precise cutting and excellent surface quality, enabling manufacturers to produce high-quality medical components efficiently.

Laser Micromachining Platforms Comparison

| Platform | Key Features | Applications |

|---|---|---|

| ML-5 | Excellent edge and surface quality, straight sidewalls | Aerospace, medical, automotive, watches |

| ML-10 | Maximized workspace, ideal for aerospace applications | Aerospace |

| MLTC | Simplifies complex machining processes, precise cutting | Medical |

These laser micromachining platforms from GF Machining Solutions offer advanced capabilities and industry-specific solutions. Whether it’s the ML-5 for precise edge and surface quality, the ML-10 for aerospace applications, or the MLTC for medical cutting processes, manufacturers can rely on these platforms to achieve optimal results in their micromachining operations.

Conclusion

Laser micromachining is a powerful technology that offers precise cutting, drilling, and engraving capabilities. These capabilities are essential for improving manufacturing efficiency, as they enable the production of small, high-precision parts. Whether you need industrial-grade tools or contract services, laser micromachining provides the high precision and positional accuracy required for your manufacturing needs.

With a range of laser micromachining platforms and systems available, manufacturers can choose the most suitable solution for their specific requirements. From aerospace to medical and automotive industries, laser micromachining plays a crucial role in meeting the demands of modern technology. By harnessing the precision of laser micromachining, manufacturers can achieve exceptional results in their cutting, drilling, and engraving processes.

By investing in laser micromachining, manufacturers can enhance their manufacturing efficiency. The precision cutting, drilling, and engraving provided by this technology ensure that parts are manufactured to the highest standards of accuracy. This not only improves the overall quality of the end products but also helps to reduce waste and increase productivity, resulting in cost savings.

In conclusion, laser micromachining offers a wide range of applications and benefits. Whether you are looking to improve manufacturing efficiency or achieve high-precision results, laser micromachining is a technology that can deliver the desired outcomes. With its precision cutting, drilling, and engraving capabilities, laser micromachining is a valuable tool for manufacturers across various industries.

FAQ

What is laser micromachining?

Laser micromachining is a process that uses focused laser beams to cut, drill, or engrave small and precise patterns on various materials.

What kind of materials can be processed with laser micromachining?

Laser micromachining can be used on a wide variety of materials, including metals, polymers, ceramics, glass, and even flexible substrates.

What industries can benefit from laser micromachining?

Laser micromachining has applications in industries such as aerospace, medical, automotive, and watch manufacturing, where high precision and miniaturization are crucial.

What laser micromachining services do you offer?

We offer a range of laser micromachining services, including laser milling, drilling, cutting, engraving, welding, and more.

What are the advantages of using laser micromachining tools?

Laser micromachining tools offer high precision, positional accuracy, and the ability to process a wide range of materials. They also provide efficient and cost-effective manufacturing solutions.

What types of laser micromachining tools do you provide?

We offer a range of laser micromachining tools, including the efficient and robust ‘C Series,’ the versatile and customizable ‘E Series,’ the advanced and innovative ‘G Series,’ the powerful and precise ‘J Series,’ and more.

Can you provide custom laser micromachining solutions?

Yes, we can provide custom laser micromachining solutions tailored to specific customer needs.

What is the role of laser micromachining in the aerospace industry?

Laser micromachining helps reduce production costs and enables the drilling and shaping of mid-sized parts in the aerospace industry.

How does laser micromachining benefit medical device manufacturers?

Laser micromachining provides the precision and miniaturization capabilities required to meet stringent regulations in the medical device manufacturing industry.

How is laser micromachining used in the automotive industry?

Laser micromachining is used in the automotive industry to produce microholes in fuel injectors, improving performance and meeting emissions requirements.

Why is laser micromachining important in the watch industry?

Laser micromachining is essential in the watch industry as it allows for the creation of extremely small and tight-tolerance components.