Contents

Source: YouTube

Understanding Soldering Techniques

Introduction to Soldering

Soldering is a fundamental technique used in various industries to join parts together. Unlike welding, soldering does not involve melting the components being joined. Instead, it uses a filler metal, known as solder, which melts at a lower temperature than the parts being joined. This process allows for a strong connection once the solder solidifies. A flux is often used to aid the process by preventing oxidation and improving the wetting of the surfaces.

Comparing Soldering and Welding

Soldering offers several advantages over welding. It operates at lower temperatures, which minimizes the risk of damaging the components and reduces processing time. Additionally, soldering is more versatile when joining dissimilar materials with different melting points and is less likely to compromise coatings, such as zinc on steel. However, the need for a solder can introduce complexities, such as potential toxicity.

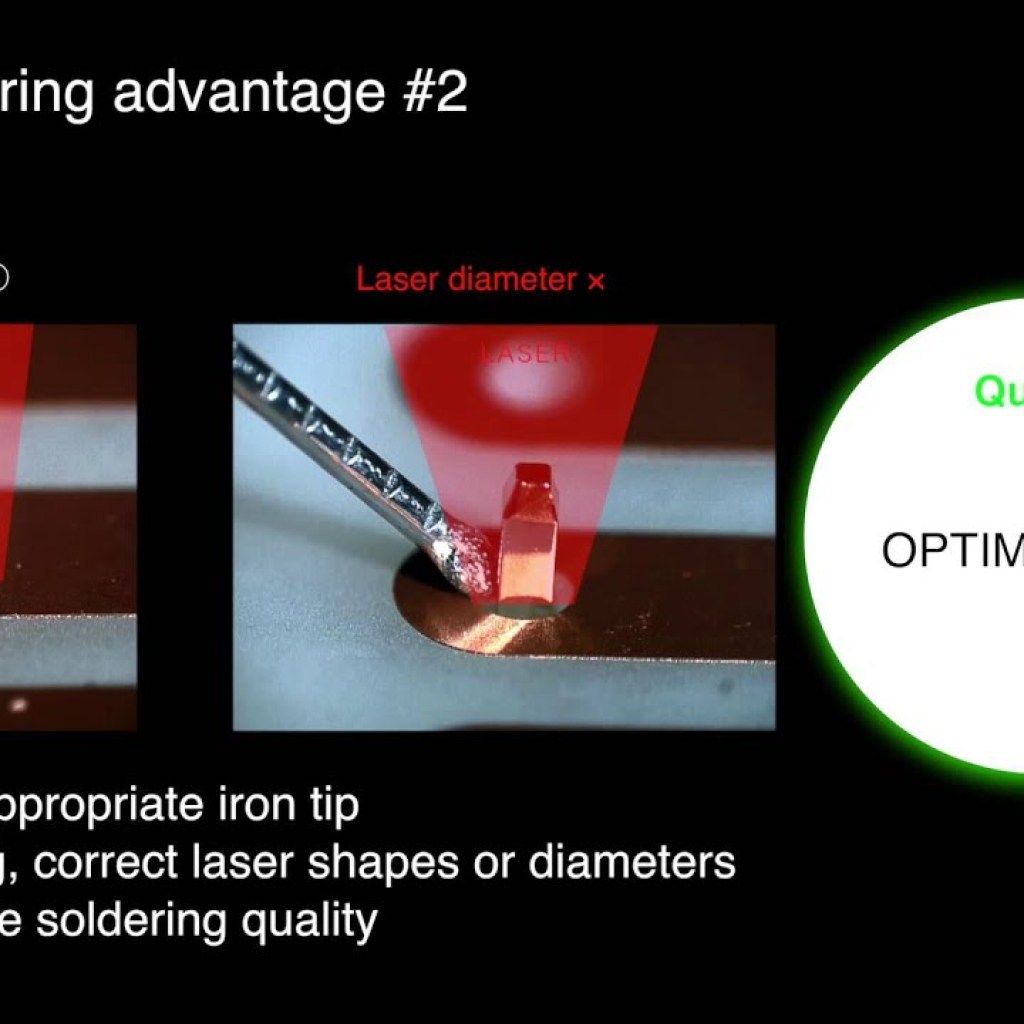

Laser Soldering Techniques

Laser soldering employs a focused laser beam to precisely heat the soldering area. This method is particularly useful for fine soldering applications in micro-electronics. The diameter of the laser beam can vary depending on the application, from less than 1 mm for fine tasks to a few millimeters for larger parts.

Soldering Heads

Specialized laser processing heads are used in laser soldering to focus the laser beam accurately on the workpiece. These heads may include integrated laser scanners for flexible positioning and facilities for applying solder in various forms, such as wire or powder. Process monitoring tools, like cameras, are often integrated to ensure precision.

Solder Materials

Common solder materials include metal alloys like tin/lead, tin/zinc, and tin/silver. For the soldering of ceramics, glass materials are used. The choice of solder depends on the application and desired properties of the joint.

Temperature Levels in Soldering

Soldering techniques are categorized based on temperature: soft soldering (below 400 °C), hard soldering (500-600 °C), and high-temperature soldering (above 450 °C, also known as brazing). Each method has specific applications and advantages, such as avoiding damage to sensitive components or creating mechanically stable connections.

Discrete Point vs. Line Soldering

Laser soldering can be performed on discrete points, as seen in connecting wires on circuit boards, or in lines for mechanical joining of parts. The choice between these methods depends on the specific requirements of the task.

Applications of Laser Soldering

Watchmaking

Laser soldering is crucial in watchmaking, particularly for attaching mainsprings in mechanical watches. The precision of laser soldering ensures accurate and reproducible results, which is vital for the functionality of the timepiece.

Automobile Manufacturing

In the automotive industry, laser soldering is used to join metal parts, such as those in car bodies. This technique is preferred over welding in certain cases due to its ability to join dissimilar metals and work around protective coatings like zinc. It also offers faster processing speeds and aesthetically pleasing joints.

Micro-electronics

Laser soldering is indispensable in micro-electronics for creating electrical contacts. Techniques like solder bumping, which involves applying small solder balls, are essential for devices with numerous closely spaced contacts, such as microprocessors.

Jewelry Fabrication

In jewelry making, fine soldering processes are employed to achieve high-quality results. Silver-based solders, requiring high temperatures, are often used, making laser soldering a preferred method for its precision and ability to handle delicate structures.

Soldering of Ceramics

Even ceramics can be joined using soldering techniques with glass solders. This is particularly useful for encapsulating sensors that need to withstand high temperatures or chemical exposure. The moderate heat conductivity of ceramics and their efficient absorption of laser radiation make laser soldering an effective solution.

Conclusion

Soldering is a versatile and essential technique in various industries, offering unique advantages over other methods like welding. The precision and adaptability of laser soldering make it particularly valuable in fields requiring fine and reliable connections. As technology advances, the applications and efficiency of soldering techniques continue to expand, making it an integral part of modern manufacturing processes.

Source: Apollo Seiko

Feel free to comment your thoughts.