Contents

- 1 Basic Principles of Laser Vibrometry

- 2 Advantages and Applications of Laser Vibrometry

- 3 Different Types of Laser Vibrometers

- 4 Laser Vibrometry in Medical and Dental Fields

- 5 Laser Vibrometry in Art and Cultural Heritage Preservation

- 6 Conclusion

- 7 FAQ

- 7.1 What is laser vibrometry?

- 7.2 How does laser vibrometry work?

- 7.3 What are the advantages of laser vibrometry?

- 7.4 Where is laser vibrometry used?

- 7.5 What types of laser vibrometers are available?

- 7.6 How is laser vibrometry used in the medical field?

- 7.7 What role does laser vibrometry play in art and cultural heritage preservation?

- 8 Source Links

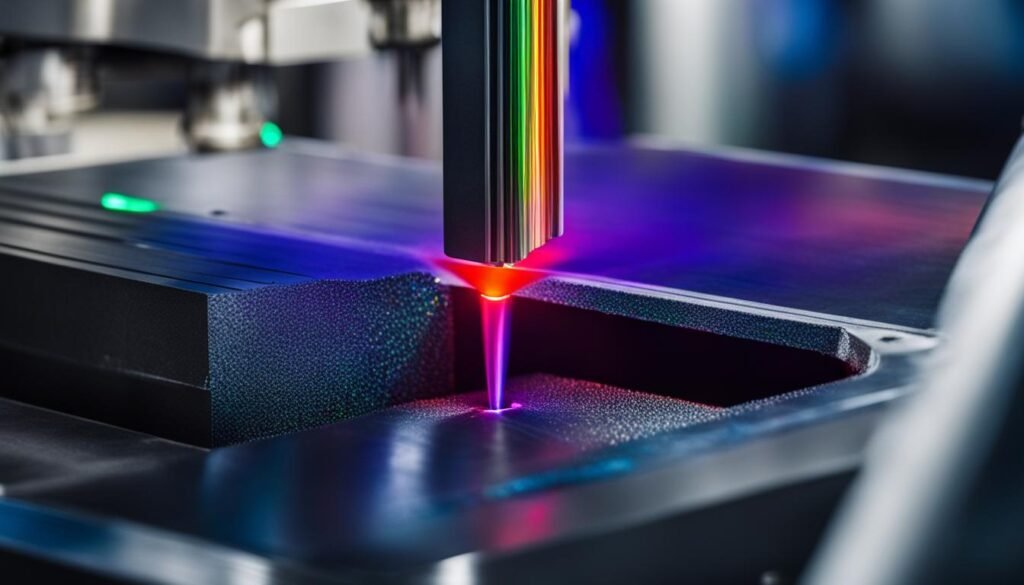

Laser vibrometry technology has revolutionized precision measurements across various industries. This highly precise method, also known as laser Doppler vibrometry (LDV), offers unbeatable displacement and velocity resolution, making it an indispensable tool in scientific research, industrial applications, and medical diagnostics.

Operating on the principle of optical interference and the Doppler effect, laser vibrometry allows for precise measurements of vibrations in structures of all sizes. Its accuracy and non-invasive nature have made it widely used in fields such as aerospace, automotive, acoustics, and materials research.

Key Takeaways:

- Laser vibrometry provides high-resolution measurements with unbeatable displacement and velocity resolution.

- It operates on the principle of optical interference and the Doppler effect.

- This technology is widely used in various scientific and industrial fields for its accuracy and non-invasive nature.

- Laser vibrometers offer flexibility and versatility in measuring vibrations in different settings and structures.

- From aerospace to art preservation, laser vibrometry plays a crucial role in advancing precision measurements.

Basic Principles of Laser Vibrometry

Laser vibrometry is a measurement technique that utilizes the Doppler effect and interferometry to accurately measure vibrations in objects. The Doppler effect refers to the shift in frequency of backscattered light from a vibrating object, which can be used to determine the velocity of the object. Interferometry, on the other hand, involves the interference of two coherent light beams to create a modulated interference pattern that corresponds to the object’s vibration.

This technique relies on the principle that the vibration of an object affects the phase of the light waves, resulting in changes in the interference pattern. By analyzing this pattern, laser vibrometry can precisely measure the velocity of the vibrating object. The measurement is non-contact, making it ideal for delicate or hard-to-reach surfaces.

One of the key advantages of laser vibrometry is its high accuracy and resolution. It can measure vibrations with exceptional precision, allowing for detailed analysis of various structures and materials. This makes it a valuable tool in fields such as aerospace, automotive, acoustics, and materials research.

Table: Advantages of Laser Vibrometry

| Advantages |

|---|

| High accuracy and resolution |

| Non-contact measurement |

| Suitable for delicate surfaces |

| Ideal for hard-to-reach areas |

| Wide range of applications |

Laser vibrometry has become an indispensable tool in various industries and research fields. Its ability to provide precise measurements of vibrations has contributed to advancements in understanding structural dynamics, improving product designs, and enhancing quality control processes. With its basic principles rooted in the Doppler effect and interferometry, laser vibrometry continues to play a crucial role in the pursuit of accurate and reliable vibration analysis.

Advantages and Applications of Laser Vibrometry

Laser vibrometry offers numerous advantages over traditional measurement devices, making it a versatile and valuable tool in various industries. One of the key advantages is its non-contact nature, allowing for measurements to be taken on delicate or hard-to-reach surfaces without compromising accuracy. Unlike accelerometers which require physical contact, laser vibrometry does not introduce any additional mass or disturbance to the target, ensuring precise measurements are obtained. This advantage makes laser vibrometry particularly well-suited for applications in micro-electromechanical systems (MEMS) and industries such as aerospace, automotive, architecture, and biological research.

Beyond its non-contact feature, laser vibrometry also offers exceptional accuracy and resolution. The technology is capable of detecting and measuring even the slightest vibrations, providing valuable insights into the behavior and dynamics of structures. This level of precision enables scientists, engineers, and researchers to gain a deeper understanding of vibrations in various applications. Moreover, laser vibrometry can be used for calibration purposes, ensuring the accuracy of other measurement systems. Its reliability and accuracy make it an indispensable tool in research and development.

The applications of laser vibrometry are broad and diverse. In the aerospace industry, laser vibrometry is used to assess and analyze the vibrations of aircraft components, helping to improve design and ensure structural integrity. In automotive engineering, it is utilized for quality control, investigating the vibrations of different vehicle parts under various conditions. Laser vibrometry also plays a critical role in architectural acoustics, allowing designers to study the vibrations of buildings and optimize their acoustic performance. Additionally, the technology is used in materials research, helping to analyze the vibrations of different materials and their response to external forces.

| Industry/Application | Advantages of Laser Vibrometry |

|---|---|

| Aerospace | Accurate assessment of aircraft component vibrations for design and safety improvements. |

| Automotive | Precision measurements of vibration for quality control and performance optimization. |

| Architecture | Analysis of building vibrations to enhance acoustic performance and structural integrity. |

| Materials Research | Study of material vibrations and response to external forces for various applications. |

In conclusion, laser vibrometry offers significant advantages over traditional measurement devices, making it an essential tool in scientific research, industrial applications, and beyond. Its non-contact nature, high precision, and versatility enable accurate measurements in challenging environments and delicate surfaces. With its widespread applications in aerospace, automotive, architecture, and materials research, laser vibrometry continues to drive innovation and advance our understanding of vibrations in various industries.

Different Types of Laser Vibrometers

Laser vibrometers come in various types, each with its own advantages and applications. Understanding the different types can help researchers and professionals choose the right instrument for their specific needs. The following are some of the most common types of laser vibrometers:

Single-Point Vibrometers

Single-point vibrometers are the most common type of laser vibrometers. They are used to measure vibrations in one directional out-of-plane movement. This type of vibrometer is ideal for applications where precise measurements of a single point are required.

Scanning Vibrometers

Scanning vibrometers utilize X-Y scanning mirrors to move the laser beam across the surface of interest. This allows for measurements at multiple locations, providing a more comprehensive understanding of the vibration profile. Scanning vibrometers are often used in applications where spatial distribution of vibrations needs to be analyzed.

Differential Vibrometers

Differential vibrometers are designed to measure the velocity difference between two locations on the target. This type of vibrometer is useful in applications where relative motion between two points needs to be quantified. It can provide valuable insights into the dynamic behavior of structures and systems.

Multi-Beam Vibrometers

Multi-beam vibrometers are capable of measuring velocity at several locations simultaneously. They use multiple laser beams to capture vibrations at different points on the target simultaneously, providing a holistic view of the system’s dynamics. This type of vibrometer is often used in complex systems and large-scale structures.

| Type | Advantages | Applications |

|---|---|---|

| Single-Point Vibrometers | – Most common type of vibrometer – Precise measurements of a single point |

– Aerospace – Automotive – Acoustics – Materials research |

| Scanning Vibrometers | – Measurements at multiple locations – Comprehensive vibration profile |

– Structural analysis – Modal analysis – Product testing |

| Differential Vibrometers | – Measure velocity difference between two points – Quantify relative motion |

– Structural dynamics – Machinery monitoring – Condition monitoring |

| Multi-Beam Vibrometers | – Simultaneous measurements at multiple locations – Holistic view of system dynamics |

– Large-scale structures – Complex systems – Civil engineering |

Laser Vibrometry in Medical and Dental Fields

Laser vibrometry, with its precise and non-invasive measurement capabilities, has found valuable applications in the medical and dental fields. This technology has been instrumental in advancing medical diagnostics and improving dental procedures, offering new possibilities for research and patient care.

Applications in Medical Research

One significant application of laser vibrometry in the medical field is non-invasive measurements of cardiac activity. By detecting the subtle vibrations of the heart, this technology enables the monitoring of heart function with high accuracy and without the need for invasive procedures. This has proven invaluable in diagnosing and tracking various cardiovascular conditions.

Advancements in Dental Procedures

In the dental industry, laser vibrometry has been used to measure the vibration signature of dental scalers, which are commonly used in dental cleanings. By analyzing the vibration patterns, dentists can optimize the quality and effectiveness of these procedures, ensuring better patient outcomes and improved oral health.

Non-Invasive Middle-Ear Diagnostics

In addition to its applications in medical research and dental procedures, laser vibrometry has also been employed in middle-ear diagnostics. By assessing the vibrations of the middle ear, this technology aids in the detection of hearing loss and provides valuable insights into middle-ear function. It offers a non-invasive alternative to traditional diagnostic methods, allowing for more comfortable and accurate assessments of patients.

These applications highlight the potential of laser vibrometry in advancing medical and dental diagnostics. By offering precise and non-invasive measurements, this technology continues to play a crucial role in improving patient care and enhancing our understanding of the human body.

| Applications | Benefits |

|---|---|

| Non-invasive cardiac activity measurement | – Accurate monitoring of heart function |

| Dental scaler vibration analysis | – Improved quality of dental procedures |

| Middle-ear diagnostics | – Non-invasive evaluation of hearing loss and middle-ear function |

Table: Applications of Laser Vibrometry in Medical and Dental Fields

Laser Vibrometry in Art and Cultural Heritage Preservation

Laser vibrometry technology has extended its applications beyond traditional scientific and industrial fields and has found a significant role in the preservation of art and cultural heritage. By offering a non-invasive and precise method, laser vibrometry has revolutionized the assessment and conservation of valuable artworks and historical artifacts. Its ability to detect structural defects, measure vibrations, and assess the impact of external forces has proven invaluable in the field.

One of the key applications of laser vibrometry in art preservation is the assessment of structural integrity and damage in various artworks, such as frescoes and icons. Using laser vibrometry, experts can identify detachments of frescoes and evaluate the impact of external forces without causing any further damage. This technology allows for a thorough understanding of the vibrational characteristics and structural stability of artworks, enabling effective preservation strategies.

Laser vibrometry has also been instrumental in evaluating the structural integrity of materials used in art restoration and conservation. For instance, carbon plates, commonly used in the reinforcement of fragile art pieces, can be analyzed using laser vibrometry to identify and study any defects or weaknesses. This information helps conservators make informed decisions on the best approaches to reinforce and preserve these delicate works.

Overall, laser vibrometry has become an indispensable tool in the field of art and cultural heritage preservation. Its non-invasive, precise, and versatile nature allows for the accurate assessment of structural defects, evaluation of material integrity, and understanding of vibrational characteristics. By leveraging the capabilities of laser vibrometry, experts can devise effective preservation strategies and ensure the longevity of our valuable cultural heritage.

Conclusion

The advancement of laser vibrometry technology has revolutionized precision measurements in various fields. With its high-resolution capabilities, non-invasive nature, and exceptional accuracy, laser vibrometry has become an indispensable tool in scientific research, industrial applications, and medical diagnostics.

From aerospace to art preservation, laser vibrometry has proven its versatility and reliability in measuring vibrations in different settings and structures. The different types of laser vibrometers, including single-point, scanning, differential, and multi-beam, offer flexibility and precision in capturing vibration data.

By harnessing the principles of the Doppler effect and interferometry, laser vibrometry enables researchers and professionals to make highly accurate measurements of vibrations. This technology has not only improved our understanding of vibrations but has also paved the way for advancements in fields such as aerospace engineering, automotive industry, acoustics, materials research, medical diagnostics, and art preservation.

With its ability to provide precise and non-contact measurements, laser vibrometry continues to push the boundaries of what is possible in the realm of precision measurements. As technology continues to evolve, we can expect laser vibrometry to further enhance our understanding of vibrations and their impact on diverse fields.

FAQ

What is laser vibrometry?

Laser vibrometry is a highly precise measurement method that utilizes the Doppler effect and optical interference to measure vibrations in structures of all sizes.

How does laser vibrometry work?

Laser vibrometry works by measuring the frequency shift of backscattered light from a vibrating object using a laser interferometer. The velocity of the object can be determined by measuring this frequency shift at a known wavelength.

What are the advantages of laser vibrometry?

Laser vibrometry offers several advantages, including non-contact measurement, high accuracy, and the ability to measure vibrations on delicate surfaces without mass-loading the target.

Where is laser vibrometry used?

Laser vibrometry is widely used in scientific research, industrial applications, medical diagnostics, and art and cultural heritage preservation.

What types of laser vibrometers are available?

There are several types of laser vibrometers, including single-point vibrometers, scanning vibrometers, differential vibrometers, and multi-beam vibrometers.

How is laser vibrometry used in the medical field?

Laser vibrometry is used for non-invasive measurements of cardiac activity, middle-ear diagnostics, and evaluating the vibration signature of dental scalers.

What role does laser vibrometry play in art and cultural heritage preservation?

Laser vibrometry is used to assess structural defects and damage in artworks, detect detachments of frescoes, and evaluate the structural integrity of materials like carbon plates.