Contents

Source: HBM

Understanding Optical Strain Sensors

Introduction to Optical Strain Sensors

Optical strain sensors, also known as strain gauges, are devices used to measure mechanical deformation caused by compressive or tensile forces. These sensors predominantly utilize fiber optics technology, offering a range of advantages over traditional mechanical and electronic strain sensors. They are particularly valued for their ability to operate across a broad temperature range, their resistance to electromagnetic interference, and their capacity to function without electrical cables, making them ideal for high-voltage applications.

Principles of Operation

Fiber Bragg Gratings

One common type of optical strain sensor is based on Fiber Bragg Gratings (FBGs). These sensors operate by detecting changes in the Bragg wavelength, which occurs when strain alters the grating period. The shift in wavelength can be analyzed using an optoelectronic interrogator, providing precise strain measurements. FBG-based sensors are often attached to mechanical components, such as building structures, to monitor strain levels effectively.

Temperature Compensation Techniques

Optical strain sensors are sensitive to both strain and temperature changes, necessitating methods for temperature compensation. Techniques include using a secondary grating exposed solely to temperature changes, employing a push-pull configuration, or utilizing additional temperature sensors to adjust strain measurements.

Dynamic Strain Sensing

For applications requiring high bandwidth, such as acoustic phenomena investigations, FBG-based sensors can be complemented with faster detection schemes. These systems can achieve sensitivities better than 1 nano-strain (nε) within a 1-Hz bandwidth.

Advanced Optical Strain Sensors

Quasi-Distributed Sensors

Quasi-distributed sensors leverage multiple FBGs within a long optical fiber, enabling the use of a single interrogator. These systems can distinguish signals using time division multiplexing (TDM) or wavelength division multiplexing (WDM), allowing for cost-effective multi-point sensing solutions.

Interferometric Sensors

Interferometric sensors utilize pairs of Bragg gratings to form Fabry–Pérot interferometers, measuring strain via shifts in resonance frequencies. These sensors can be integrated into a single fiber, offering dynamic sensing capabilities for applications like vibration monitoring.

Micro-Fabry–Pérot Sensors

Micro-Fabry–Pérot sensors employ small interferometers with mirror distances affected by strain. These sensors can operate at higher temperatures than FBG-based sensors and offer high strain resolution, although they are typically used as standalone units rather than in distributed systems.

Distributed Strain Sensing Technologies

Rayleigh Scattering-Based Sensors

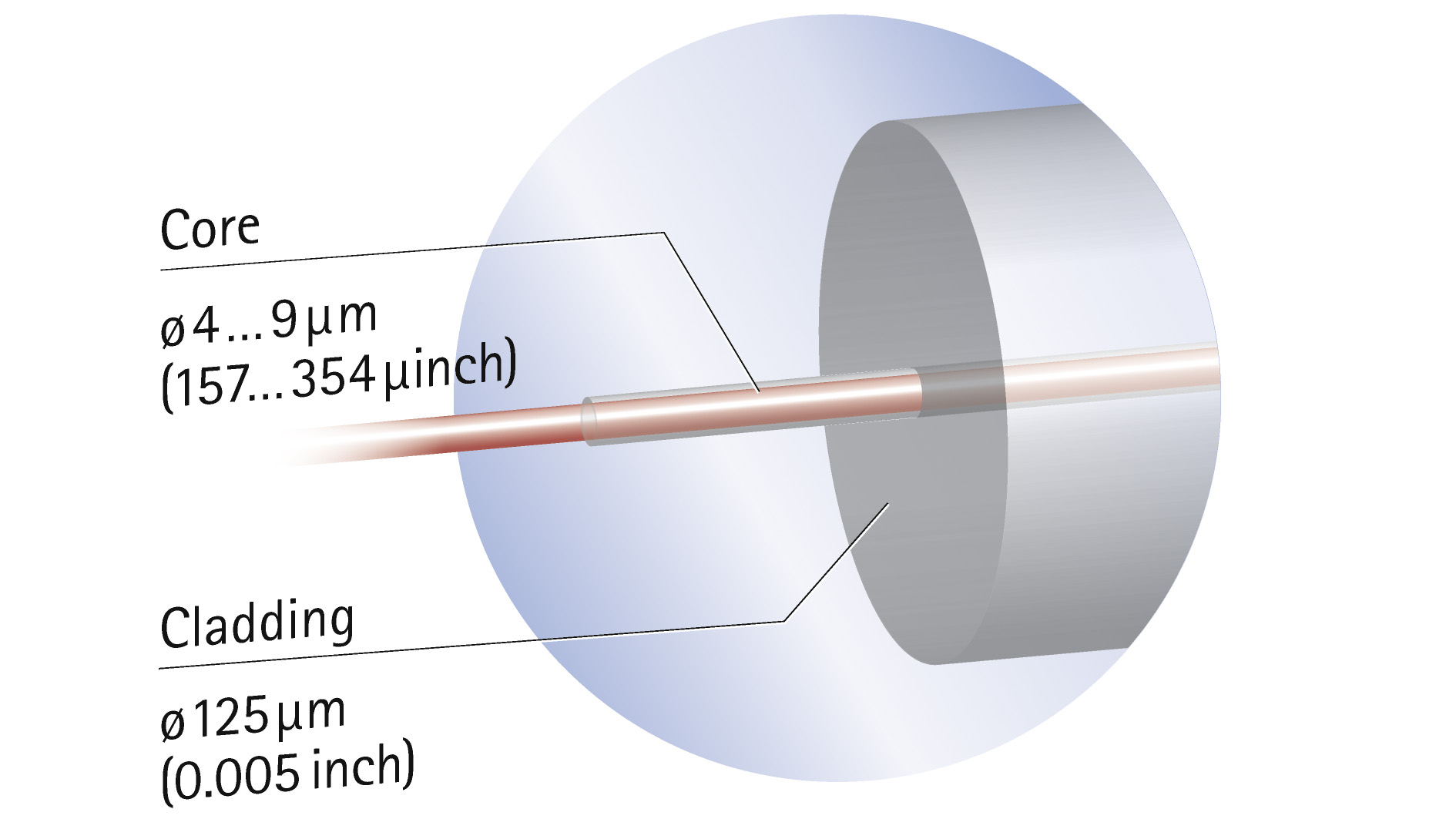

Distributed fiber-optic strain sensors can exploit Rayleigh scattering in standard single-mode fibers. This approach provides high spatial resolution, making it suitable for monitoring strain over limited lengths, such as a few dozen meters.

Brillouin Scattering-Based Sensors

For longer fiber applications, Brillouin scattering techniques are employed. These methods analyze spontaneous or stimulated Brillouin scattering to measure strain and temperature over extensive distances, often exceeding 10 kilometers. They are particularly useful for monitoring infrastructure like pipelines.

Applications of Optical Strain Sensors

Optical strain sensors find widespread applications in structural health monitoring of infrastructure such as bridges, tunnels, and pipelines. They are also used in the development phase of technologies to conduct fatigue tests under controlled conditions, ensuring reliability and safety in normal operations.

Conclusion

Optical strain sensors offer a versatile and precise solution for measuring mechanical deformation across various applications. Their ability to operate in challenging environments without interference makes them indispensable in modern engineering and monitoring systems. As technology advances, these sensors will continue to play a crucial role in ensuring the safety and efficiency of critical infrastructure.

Source: Tacuna Systems

Feel free to comment your thoughts.