Contents

Source: SPIE

Understanding Single-Crystal Fibers in Photonics

Single-crystal fibers are a fascinating and innovative component in the field of photonics, offering unique properties for various optical applications. This blog post delves into the intricacies of single-crystal fibers, their fabrication methods, materials used, and their comparison with traditional glass fibers.

What Are Single-Crystal Fibers?

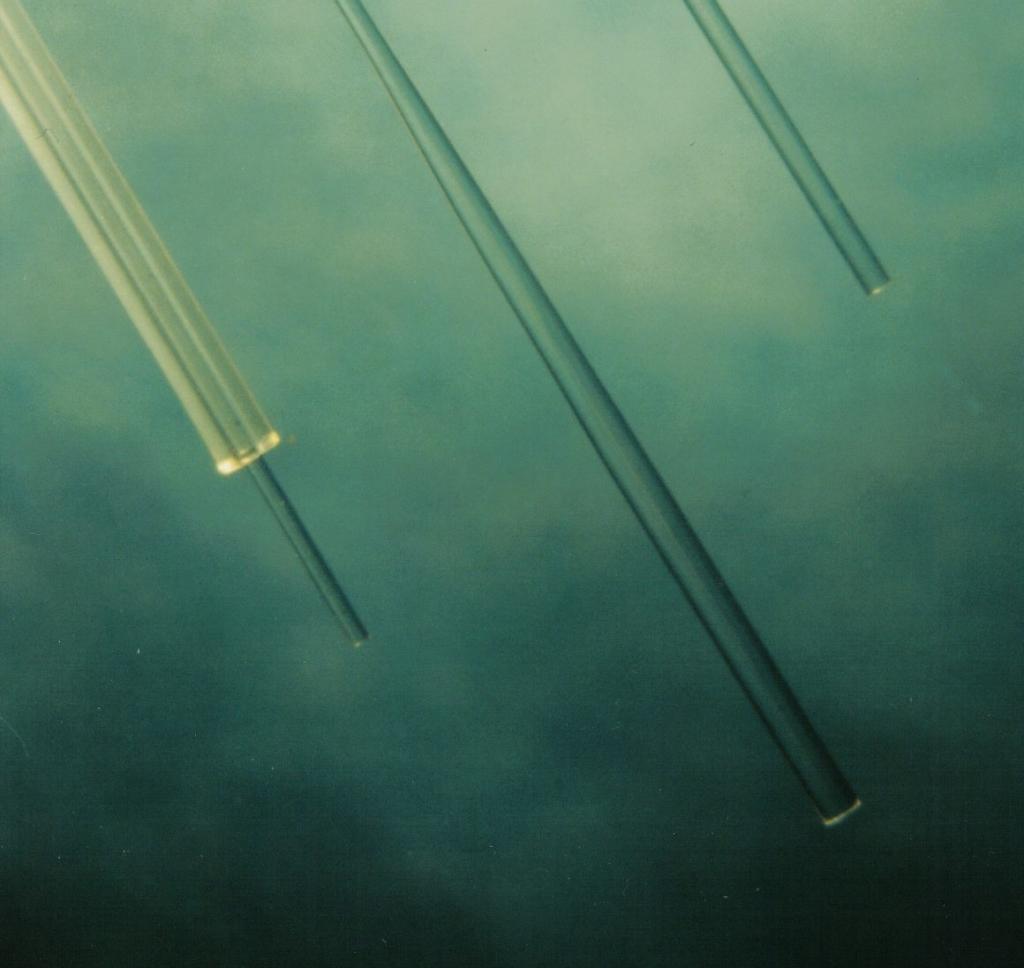

Single-crystal fibers are long, slender rods composed of monocrystalline materials. Typically, these fibers have diameters less than 1 mm and can range in length from 10 cm to several meters. Due to their geometry, they are referred to as fibers, although many do not possess the flexibility required for substantial bending.

Applications of Single-Crystal Fibers

While single-crystal fibers are primarily used in optical applications, they also have mechanical uses, such as in suspensions for highly sensitive interferometers. Despite significant research over the years, their application in laser technology remains largely experimental.

Optical Applications

In optical applications, single-crystal fibers serve as laser-active devices when doped with rare-earth ions like Yb3+, Nd3+, Er3+, or transition metal ions such as Ti3+. These fibers are especially suitable for high-power levels in ultrashort pulse amplification.

Fabrication Methods of Single-Crystal Fibers

Laser-Heated Pedestal Growth (LHPG)

The most prevalent method for fabricating single-crystal fibers is the laser-heated pedestal growth technique. In this process, a monocrystalline rod is heated with a laser and slowly pulled upwards, resulting in a fiber that is typically three times smaller in diameter than the source crystal. This method minimizes contamination due to the absence of a crucible.

Edge-Defined Film-Fed Growth (EFG)

Edge-defined film-fed growth is an alternative technique that allows for faster fiber growth. Here, the growth material is supplied through capillaries, and multiple fibers can be grown simultaneously. However, this method may introduce contaminants from the die material.

Micro-Pulling-Down Method (μ-PD)

The micro-pulling-down method is a variant of film-fed growth where the crystal is pulled downward. This method can achieve a monocrystalline structure under well-controlled conditions, although some quality is lost when the source material melts.

Materials Used in Single-Crystal Fibers

Single-crystal fibers are commonly made from oxide crystal materials due to their chemical and mechanical stability. Notable materials include:

- Sapphire (Al2O3): Known for its hardness and high thermal conductivity, sapphire has a wide transparency range extending into the infrared region.

- YAG (Y3Al5O12): YAG is a hard material that can be doped with various rare-earth laser gain media.

- Other Oxides: Materials like GGG (Gd3Ga5O12) and spinel (MgAl2O4) share similar properties with YAG.

In addition to oxides, other materials such as fluoride crystals, nonlinear crystals like lithium niobate, and semiconductors like silicon and germanium can be used in more experimental stages.

Comparison with Glass Fibers

Single-crystal fibers share a similar geometric shape with optical glass fibers but differ significantly in structure and properties. Unlike glass fibers, single-crystal fibers typically do not have a core-cladding structure, which poses challenges for single-mode guidance.

Despite these differences, single-crystal fibers have advantages such as higher optical damage thresholds and suitability for high-power applications. They also allow for higher doping concentrations of laser-active ions, resulting in stronger pump absorption and higher gain.

Conclusion

Single-crystal fibers represent a unique and promising technology in the field of photonics. Their ability to operate at high-power levels and in ultrashort pulse amplification makes them valuable for specific applications. As research continues, we can expect further advancements in their fabrication and application.

Source: IDIL Fibres Optiques

Feel free to comment your thoughts.