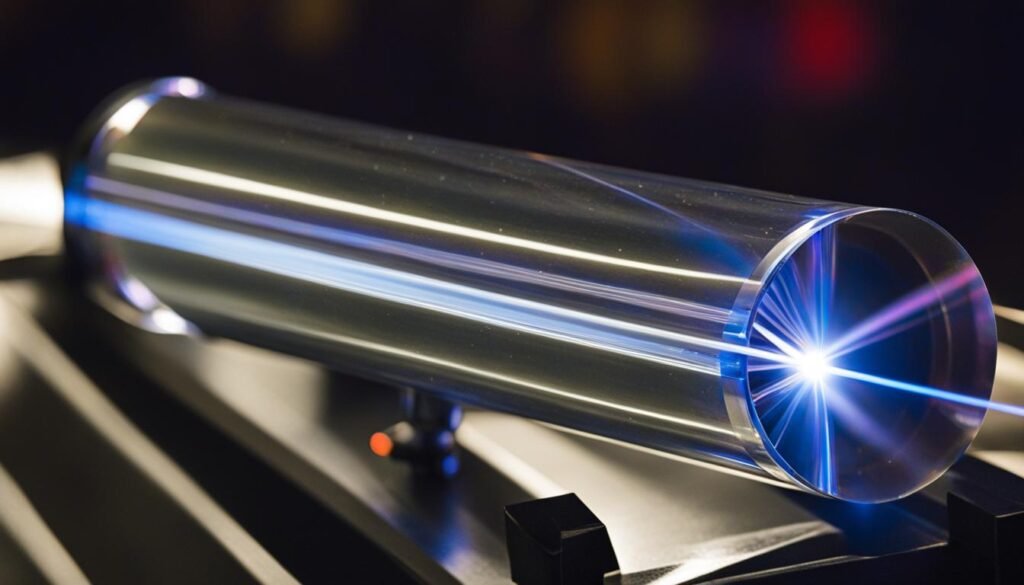

Welcome to our comprehensive guide on solid-state lasers. In this article, we will explore the fascinating world of laser technology, its applications, materials, and systems. Whether you are curious about laser cutting, laser marking, or laser engraving, this guide will provide you with valuable insights into the world of solid-state lasers.

Contents

Key Takeaways:

- Solid-state lasers utilize a solid medium as the gain medium, offering stability, efficiency, and versatility.

- Common types of solid-state lasers include Nd:YAG, Erbium-Doped Fiber, Ti:Sapphire, Ho:YAG, and Ruby lasers.

- These lasers operate on the principle of stimulated emission, emitting coherent light when stimulated by an external source.

- Advantages of solid-state lasers include high beam quality, efficient energy conversion, compact design, and precise control of output.

- They find applications in various fields such as medicine, manufacturing, scientific research, communication, and military defense.

Types of Solid-State Lasers

Solid-state lasers come in various types, each designed for specific applications. These lasers utilize a solid medium as the gain medium, offering stability, efficiency, and versatility. Let’s explore some of the most common types of solid-state lasers:

1. Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) lasers:

These lasers are widely used and offer high energy output. The neodymium-doped yttrium aluminum garnet crystal provides the necessary characteristics for efficient laser operation. Nd:YAG lasers find applications in areas such as material processing, laser cutting, and welding.

2. Erbium-Doped Fiber lasers:

Erbium-doped fiber lasers are popular in telecommunications due to their excellent stability and efficiency. The erbium ions embedded within the fiber optic cable enable amplification of light signals, making them crucial for long-distance communication systems.

3. Titanium Sapphire (Ti:Sapphire) lasers:

Titanium Sapphire lasers are known for their tunability in the visible and near-infrared range. This versatility makes them valuable in scientific research, specifically in areas such as spectroscopy and ultrafast pulsed lasers.

4. Holmium Yttrium Aluminum Garnet (Ho:YAG) lasers:

Ho:YAG lasers are used in medical procedures and military applications. The holmium ions provide specific wavelengths that are absorbed by water, making these lasers ideal for precise tissue ablation and other surgical procedures.

5. Ruby lasers:

Considered the first solid-state lasers, ruby lasers emit red light and are still used in some applications. These lasers harness the chromium-doped ruby crystal for laser emission, providing a distinct wavelength that finds applications in research and industrial processes.

Each type of solid-state laser has unique properties and advantages, making them suitable for different purposes. Understanding these variations allows users to select the most appropriate laser technology for their specific applications.

How Solid-State Lasers Work

Solid-state lasers operate on the principle of stimulated emission, similar to other lasers. The solid medium of a solid-state laser, which can be a crystalline or glass material, is doped with atoms or ions that absorb energy and emit coherent photons when stimulated by an external light source or electrical discharge. This process results in the generation of a laser beam with specific characteristics, such as wavelength, power, and beam quality. The solid-state nature of the gain medium contributes to the stability, efficiency, and versatility of these lasers.

A key component of solid-state lasers is the gain medium, also known as the solid medium or laser medium. This medium serves as the source of stimulated emission, where the atoms or ions absorb energy and transition to higher energy levels. When stimulated by an external light source or electrical discharge, the excited atoms or ions release photons in a process known as spontaneous emission. These emitted photons can stimulate neighboring excited atoms or ions to release additional photons, resulting in the amplification of light and the generation of a coherent laser beam.

The solid-state medium of solid-state lasers offers several advantages. Firstly, it provides a stable environment for the gain medium, allowing for precise control of laser output. Secondly, the solid nature of the medium enables efficient energy transfer and high optical efficiency, meaning a larger portion of the input energy is converted into useful laser output. Additionally, the solid medium allows for compact and robust laser designs, making solid-state lasers suitable for various applications where space is limited or durability is required.

Table: Comparison of Solid-State Lasers and Other Laser Types

| Aspect | Solid-State Lasers | Gas Lasers | Liquid Lasers |

|---|---|---|---|

| Beam Quality | High | Variable | Variable |

| Efficiency | High | Medium | Medium |

| Compact Design | Yes | No | No |

| Maintenance | Low | Medium | Medium |

Solid-state lasers provide high beam quality, efficient energy conversion, compact design, and low maintenance requirements—making them superior to gas and liquid lasers in several aspects.

In conclusion, solid-state lasers operate through the process of stimulated emission in a solid medium, offering stability, efficiency, and versatility. The gain medium of solid-state lasers, doped with atoms or ions, absorbs energy and emits coherent photons when stimulated by an external light source or electrical discharge. The solid-state nature of the medium provides advantages such as precise control of laser output, efficient energy transfer, and compact design. In comparison to gas and liquid lasers, solid-state lasers demonstrate superior beam quality, efficiency, and maintenance requirements. These characteristics make solid-state lasers a preferred choice for numerous applications in various industries.

Advantages and Applications of Solid-State Lasers

Solid-state lasers offer several advantages over other types of lasers. One significant advantage is their high beam quality, which ensures a focused and precise laser beam. This is crucial in applications that require accuracy, such as laser cutting and engraving in manufacturing processes. The precise control over the output parameters, such as power and pulse duration, makes solid-state lasers ideal for tasks that demand exact specifications.

Another advantage of solid-state lasers is their efficient energy conversion. They can convert input energy into laser output with minimal waste, making them more economical and environmentally friendly. Their compact design is another notable feature that sets them apart. Solid-state lasers are smaller and more portable than other laser types, allowing for easier integration into various systems and devices.

The applications of solid-state lasers are wide-ranging and diverse. In the medical field, they are used in various procedures, including laser surgery and dermatology treatments. In manufacturing, solid-state lasers find utility in processes such as cutting, welding, and engraving, where their high beam quality and precision are invaluable. They are also widely employed in scientific research for applications such as spectroscopy and particle acceleration. In communication systems, solid-state lasers based on fiber optics enable high-speed data transmission. Additionally, solid-state lasers play a crucial role in military and defense applications, including rangefinding and target designation.

The versatility, efficiency, and beam quality of solid-state lasers make them indispensable in numerous industries. With ongoing advancements in laser technology, their applications continue to expand, and we can expect to see even greater utilization of solid-state lasers in the future.

Table: Applications of Solid-State Lasers

| Industry | Applications |

|---|---|

| Medical | Laser surgery, dermatology, ophthalmology |

| Manufacturing | Laser cutting, welding, engraving |

| Scientific Research | Spectroscopy, particle acceleration, microscopy |

| Communication | Fiber optic communication systems |

| Military and Defense | Rangefinding, target designation, laser guidance |

Solid-State Lasers vs. Other Laser Types

When comparing solid-state lasers to gas and liquid lasers, several key advantages become apparent. One of the standout features of solid-state lasers is their superior beam quality. With a focused and precise laser beam, solid-state lasers are highly effective in applications requiring accuracy and precision.

In terms of efficiency, solid-state lasers also outperform their gas and liquid counterparts. These lasers have a higher energy conversion rate, meaning that they can convert input energy into laser output more effectively. This efficiency translates to lower energy consumption and reduced operating costs.

Furthermore, solid-state lasers are known for their compact design. This compactness makes them easier to integrate into systems and reduces the overall space required. Compared to gas and liquid lasers, solid-state lasers are more versatile and can be utilized in diverse environments with limited space constraints.

“Solid-state lasers provide superior beam quality, higher efficiency, and a compact design, making them the preferred choice in many applications.”

Comparison of Solid-State, Gas, and Liquid Lasers

| Solid-State Lasers | Gas Lasers | Liquid Lasers | |

|---|---|---|---|

| Beam Quality | High | Varies | Varies |

| Efficiency | High | Medium | Medium |

| Compact Design | Yes | No | No |

| Maintenance | Low | High | High |

Aside from their technical advantages, solid-state lasers also require less maintenance compared to gas and liquid lasers. This reduced maintenance is due to the absence of consumables and the robustness of solid-state laser technology. As a result, solid-state lasers offer improved efficiency and reliability for long-term use.

With their beam quality, efficiency, compact design, and reduced maintenance needs, solid-state lasers have become the preferred choice for a wide range of applications. From industrial manufacturing to medical procedures, solid-state lasers are revolutionizing various industries and driving advancements in laser technology.

Conclusion

Solid-state lasers have revolutionized various industries with their precision, efficiency, and versatility. Their impact is profound and ever-expanding, spanning from medical procedures to cutting-edge research. As technology continues to evolve, solid-state lasers are expected to play a significant role in emerging fields like quantum computing and space exploration.

Their potential for further advancements and innovative applications is promising, making solid-state lasers a key technology in our modern world.

FAQ

What are solid-state lasers?

Solid-state lasers are lasers that utilize a solid medium as the gain medium, offering stability, efficiency, and versatility.

What are the common types of solid-state lasers?

Common types of solid-state lasers include Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG) lasers, Erbium-Doped Fiber lasers, Titanium Sapphire (Ti:Sapphire) lasers, Holmium Yttrium Aluminum Garnet (Ho:YAG) lasers, and Ruby lasers.

How do solid-state lasers work?

Solid-state lasers operate on the principle of stimulated emission, emitting coherent light when stimulated by an external source.

What are the advantages and applications of solid-state lasers?

Solid-state lasers offer advantages such as high beam quality, efficient energy conversion, compact design, and precise control of output. They find applications in numerous fields, including medicine, manufacturing, scientific research, communication, and military defense.

How do solid-state lasers compare to other laser types?

Solid-state lasers outperform gas and liquid lasers in terms of beam quality and efficiency. They also have a more compact design and require less maintenance.

What is the future outlook for solid-state lasers?

Solid-state lasers have promising future prospects, particularly in fields like quantum computing and space exploration. As technology advances, their performance and applications are expected to expand further.