Laser scanning technology has revolutionized various industries, offering a wide range of applications and possibilities. Whether it’s reading barcodes, projecting mesmerizing light shows, or performing intricate industrial processes, laser scanners have become indispensable tools in today’s world.

So, how does a laser scanner work? It all starts with a laser beam. The scanner moves this beam across a surface, gathering data or performing specific tasks. The process involves several components and principles, each contributing to the scanner’s functionality and efficiency.

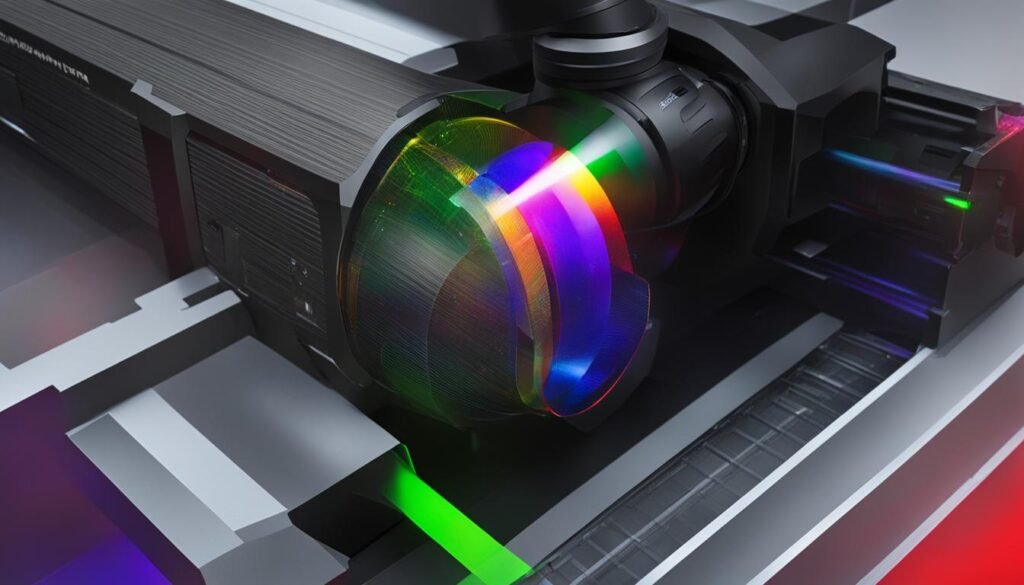

One of the key components of a laser scanner is the lens. Different lenses are used to achieve desired focal points and optimize the scanning process. The selection of lenses plays a crucial role in determining the accuracy, resolution, and range of the scanner’s capabilities.

Contents

Key Takeaways:

- Laser scanning technology has revolutionized various industries with its wide range of applications.

- A laser scanner works by moving a laser beam across a surface to gather data or perform specific tasks.

- The selection of lenses in laser scanning is crucial for achieving desired focal points and optimizing the scanning process.

- Laser scanners are composed of different components and principles that contribute to their functionality and efficiency.

- Understanding how laser scanners work and the different lenses used is essential for utilizing them effectively in various applications.

Understanding Galvanometer Scanners, Polygon Scanners, and Acousto-Optic Deflectors

Laser scanning technology relies on different scanning technologies to achieve precise control and manipulation of laser beams. Three common types of scanners used in laser scanning applications are galvanometer scanners, polygon scanners, and acousto-optic deflectors.

Galvanometer Scanners

Galvanometer scanners are widely used in various industries due to their versatility and accuracy. These scanners consist of a mirror mounted on a rotating shaft, which can be computer-controlled to move the laser beam in a specific pattern. They offer precise control over the laser beam position and speed, making them suitable for applications such as light shows, material marking and welding, biomedical imaging, and confocal microscopy.

Polygon Scanners

Polygon scanners are another type of laser scanner commonly used in high-speed scanning applications. They utilize a polygon-shaped component with mirror-coated edges that rotates at high speeds. This rotation allows the laser beam to be reflected off the polygon edges, resulting in fast and efficient scanning over large angles. Polygon scanners are often found in laser printers and LIDAR systems, where quick and accurate scanning is essential.

Acousto-Optic Deflectors

Acousto-optic deflectors employ the principles of diffraction and sound waves to deflect laser beams. They consist of a crystal or glass piece that deflects the laser beam based on the diffraction caused by an acoustic wave passing through it. These scanners offer high scan speeds, making them suitable for specialized uses in laser cooling, microscopy, and graphic arts applications.

Choosing the right scanning technology depends on the specific requirements of the laser scanning application. Factors such as scanning speed, accuracy, and angle range play a crucial role in the selection process. Additionally, considerations like cost, size, and compatibility with other components should also be taken into account.

By understanding the different types of scanners utilized in laser scanning, professionals can make informed decisions when selecting the most suitable technology for their specific applications.

Conclusion

Laser scanning technology has revolutionized various industries, offering a multitude of applications and driving advancements. From barcode scanning to industrial material processing, laser scanners have become indispensable tools in the modern world.

With different scanning technologies like galvanometer scanners, polygon scanners, and acousto-optic deflectors, laser scanners provide precise control and manipulation of laser beams. These technologies enable a wide range of applications, including light shows, biomedical imaging, laser printing, and LIDAR systems.

As laser scanner technology continues to evolve, we can expect even greater advancements. Laser scanners are becoming more efficient, faster, and capable of handling higher optical powers, opening up new possibilities for various fields. The ongoing development of laser scanner technology promises improved scanning capabilities, enhanced performance, and expanded applications.

In conclusion, laser scanning has transformed industries by offering versatile applications and driving technological advancements. As we embrace the future, laser scanners will continue to play a vital role in meeting the demands of diverse fields, fueling innovation, and enabling us to explore new frontiers.