A laser company operates on the principles of lasers and utilizes them in various industries such as manufacturing, microelectronics, and biomedical applications. The range of laser applications has expanded over the years, making lasers an indispensable tool in fields like DNA sequencing and consumer electronics manufacturing.

Contents

- 1 The Basics of Laser Operation

- 2 The Laser Cavity

- 3 Characteristics of Laser Light

- 4 Continuous-Wave Lasers

- 5 Starting a Laser Cutting Business

- 6 Laser Engraving and Customization

- 7 Benefits of Laser Engraving Business

- 8 Licensing and Equipment for Laser Engraving Businesses

- 9 Conclusion

- 10 FAQ

- 10.1 What is the structure of a laser company?

- 10.2 How do lasers work?

- 10.3 What is the laser cavity?

- 10.4 What are the characteristics of laser light?

- 10.5 What are continuous-wave lasers?

- 10.6 How can I start a laser cutting business?

- 10.7 What is laser engraving?

- 10.8 What are the benefits of a laser engraving business?

- 10.9 What equipment do I need for a laser engraving business?

- 10.10 What is the structure of a laser company?

- 11 Source Links

Key Takeaways:

- A laser company operates based on the principles of lasers and their applications in various industries.

- The laser cavity, or resonator, is at the core of a laser system, providing feedback to enhance laser output.

- Understanding the operating principles and unique characteristics of lasers is essential for starting a laser cutting or engraving business.

- Laser cutting and engraving businesses offer versatile customization services and can cater to different industries and customer demands.

- With the right equipment, planning, and marketing strategy, entrepreneurs can establish successful laser engraving businesses.

The Basics of Laser Operation

Laser operation is based on the principle of stimulated emission, where excited atoms emit identical photons when stimulated by a photon. This process amplifies light in the presence of a sufficient number of excited atoms, resulting in optical gain. The input energy for laser operation can be optical or electrical, depending on the type of laser system.

Incoherent light sources, such as lightbulbs or LEDs, produce randomly emitted photons, while lasers produce coherent photons with identical properties. The coherence of laser light enables it to travel in a straight line without spreading out. This property is crucial for applications that require precise and focused beams of light.

Furthermore, lasers have several unique properties that make them useful in various fields. Monochromaticity refers to the fact that all photons emitted by a laser have the same wavelength. This characteristic is important for applications that require specific wavelengths, such as telecommunications and spectroscopy. Laser light is also highly coherent, with all the light waves in phase with each other. This coherence enables applications like holography and interferometry.

In laser operation, excited atoms emit identical photons when stimulated by a photon, amplifying the light through a process called stimulated emission. This results in optical gain, allowing lasers to produce coherent and monochromatic light. These unique properties of laser light are essential for numerous applications in fields such as medicine, manufacturing, and communications.

Table: Comparison of Coherent and Incoherent Light

| Property | Coherent Light | Incoherent Light |

|---|---|---|

| Source | Laser | Lightbulb |

| Photon Behavior | Identical properties, in phase | Randomly emitted photons |

| Travel | Travels in a straight line without spreading | Spreads out in all directions |

| Applications | Holography, interferometry | General illumination |

In summary, laser operation is based on the process of stimulated emission, where excited atoms emit identical photons. Laser systems produce coherent and monochromatic light, which is highly useful for a wide range of applications. The unique properties of laser light enable it to be focused and directed with precision, making it an indispensable tool in various fields.

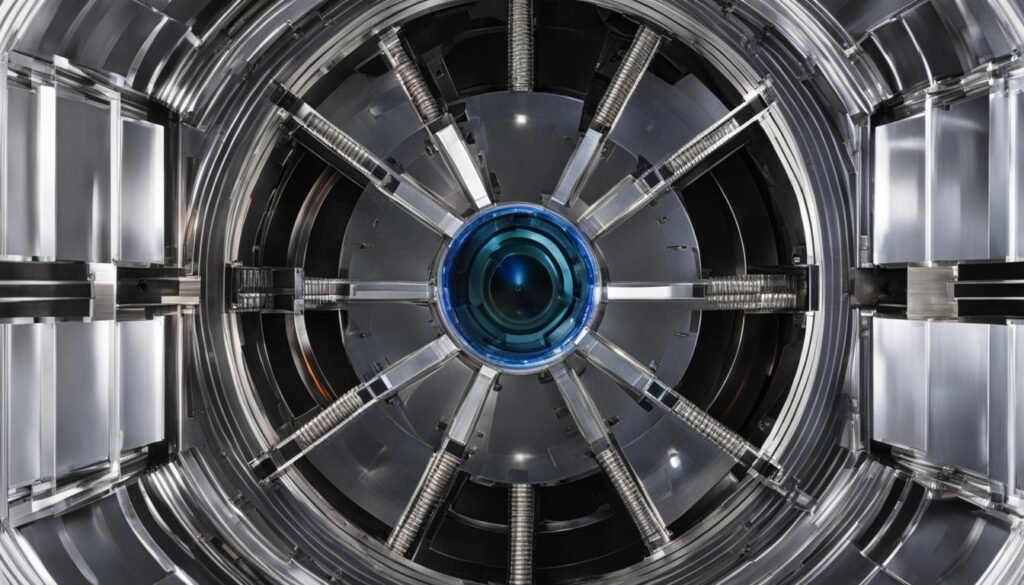

The Laser Cavity

The laser cavity, also known as the resonator, is a critical component in any laser system. It consists of two mirrors: a total reflector and a partial reflector. These mirrors enable the laser beam to bounce back and forth, amplifying its intensity with each pass through the gain medium. The gain medium, which can be a crystal, semiconductor, or gas, is positioned along the optical axis of the resonator. The optical axis defines both the direction of the laser beam’s propagation and the direction of high optical gain. Additionally, the output coupler, a partially reflecting mirror, allows a portion of the laser light to escape, resulting in the formation of the output beam.

The laser cavity’s design and alignment are crucial for ensuring optimal laser performance. The mirrors’ reflectivity determines the efficiency of light amplification, while their positioning influences the laser beam’s characteristics, such as divergence and beam quality. High-quality mirrors with low absorption and scattering ensure minimal losses and maximize laser output. The alignment of the mirrors is also essential, as any misalignment can lead to reduced efficiency, beam distortion, or even damage to the laser components.

Types of Laser Cavities

There are various types of laser cavities, each with its advantages and applications. The most common types include the Fabry-Perot cavity, the ring cavity, and the folded cavity. The Fabry-Perot cavity consists of two parallel mirrors, allowing the laser beam to bounce back and forth in a straight line. This design is simple and efficient, making it suitable for many laser systems. The ring cavity, as the name suggests, forms a ring-shaped path for the laser beam, producing a more stable and uniform beam profile. The folded cavity employs additional mirrors to extend the beam path, enabling compact laser designs while maintaining good beam quality.

Overall, the laser cavity is a fundamental element in laser technology, providing the necessary feedback to enhance laser output. Its design, alignment, and choice of materials are crucial to achieving optimal laser performance for various applications across industries.

Characteristics of Laser Light

Laser light possesses distinct characteristics that make it unique compared to conventional light sources. Understanding these characteristics is crucial for comprehending the widespread applications and advantages of lasers. Laser light is highly monochromatic, meaning that all of its photons have the same wavelength. This property allows lasers to generate a narrow, intense beam of light that can be precisely focused or transmitted over long distances with minimal divergence.

Another key characteristic of laser light is its high coherence. Coherence refers to the phase relationship between different lightwaves, with laser light exhibiting perfect coherence. This property enables applications like precision measurements and the creation of interference patterns. Laser light is exceptionally bright and exhibits high radiance, allowing it to be projected over great distances or concentrated to a small spot.

These qualities of laser light contribute to its wide range of applications across various industries. From telecommunications to manufacturing and biomedical research, lasers have revolutionized numerous fields with their unique properties. Next, we will explore continuous-wave lasers and their specific operating characteristics.

Laser Light Characteristics:

- Monochromaticity: All photons have the same wavelength.

- Coherence: Lightwaves are in perfect phase alignment.

- Brightness: Laser light is exceptionally bright and focused.

These characteristics make laser light ideal for precision applications such as spectroscopy, laser cutting, and laser engraving. With its precise control over wavelength and intensity, laser light continues to advance technology and open up new possibilities in various industries.

| Laser Light Characteristics | Description |

|---|---|

| Monochromaticity | All photons have the same wavelength. |

| Coherence | Lightwaves are in perfect phase alignment. |

| Brightness | Laser light is exceptionally bright and focused. |

Continuous-Wave Lasers

Continuous-wave (CW) lasers are a type of laser that produce a continuous, uninterrupted beam of light. These lasers are commonly used in various applications, ranging from scientific research to industrial processes. One of the key characteristics of CW lasers is their ability to emit light at specific wavelengths determined by the laser medium. Different types of lasers, such as CO2 lasers or neodymium-based crystals, have specific operating wavelengths. This wavelength specificity allows for precise targeting and control in various applications.

One important parameter for CW lasers is the linewidth, which determines the range of frequencies emitted by the laser. The linewidth can vary depending on the laser type and design. Some lasers have a broad linewidth, while others have a narrower linewidth. Narrow linewidth lasers, such as stabilized diode-pumped YAG lasers, are particularly important for applications that require high precision, such as spectroscopy or metrology. These lasers provide a more precise and accurate output, enabling researchers and engineers to achieve highly accurate measurements and analysis.

To illustrate the differences in linewidth, consider the following comparison:

| Laser Type | Linewidth (MHz) |

|---|---|

| CO2 Laser | 10,000 |

| Stabilized Diode-Pumped YAG Laser | 1 |

As seen in the table above, the CO2 laser has a much broader linewidth compared to the stabilized diode-pumped YAG laser. This difference in linewidth directly affects the precision and accuracy of the laser output. Therefore, when selecting a CW laser for a specific application, it is important to consider the required linewidth and choose a laser that meets those specifications.

Overall, continuous-wave lasers offer a reliable and continuous source of laser light at specific wavelengths. Their ability to emit light with a defined linewidth makes them suitable for a wide range of applications, from scientific research to industrial processes. By understanding the characteristics of continuous-wave lasers and their linewidth specifications, researchers and engineers can select the most appropriate laser for their specific needs.

Starting a Laser Cutting Business

Are you considering starting your own business? A laser cutting business may be the perfect venture for you. With the increasing demand for customized, artisan products, the market for laser cutting services is thriving. The best part is, starting a laser cutting business requires minimal upfront costs compared to other enterprises. This makes it an attractive option for entrepreneurs looking to break into the market.

A laser cutting business can offer a wide range of services, from producing their own designs to engraving existing objects. This versatility allows you to cater to various industries, such as fashion, arts and crafts, and merchandise. Whether you want to create intricate jewelry pieces or personalized home decor, a laser cutting business provides endless possibilities.

One of the advantages of starting a laser cutting business is its adaptability to changing trends. As consumer preferences evolve, you can easily adjust your offerings to meet the demands of the market. This ensures that your business remains relevant and competitive in the long run. With the right planning and marketing strategy, your laser cutting business can become a go-to destination for customers seeking unique, customized products.

So, if you’ve been dreaming of starting your own business but worried about high startup costs, consider venturing into the exciting world of laser cutting. With its low initial investment and diverse range of services, a laser cutting business can be a profitable and fulfilling endeavor. Make your mark in the industry by offering high-quality, personalized products that customers will love.

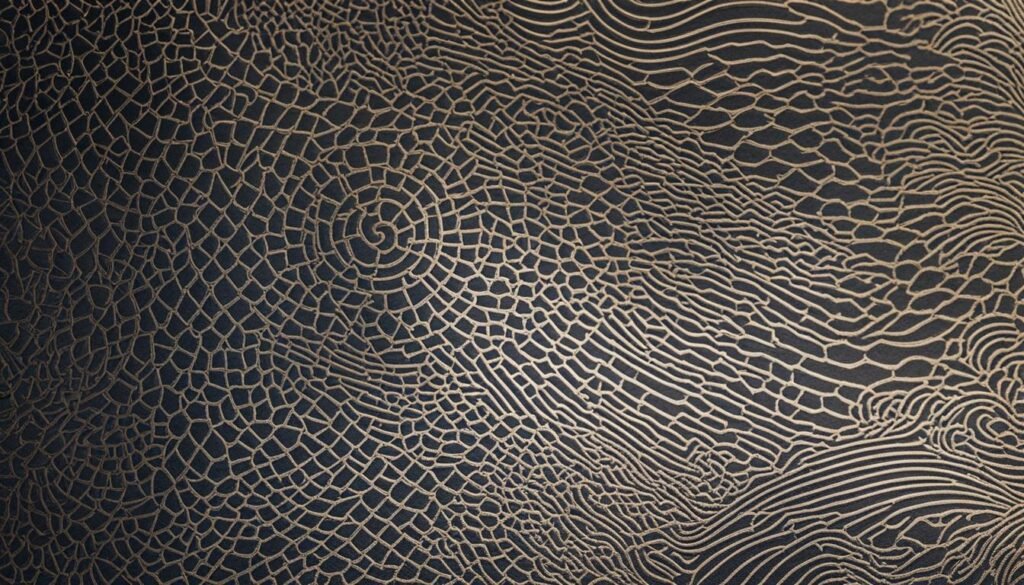

Laser Engraving and Customization

Laser engraving is a versatile method of customization that has gained significant popularity in recent years. This technique involves using a laser to remove material from the surface of an object, creating permanent marks or designs. Laser engraving can be done on various materials, including acrylic, wood, leather, fabric, and glass, making it suitable for a wide range of applications.

One of the key advantages of laser engraving is its precision. The laser beam is controlled by a computer, allowing for intricate and detailed designs to be engraved with accuracy. This level of precision is especially beneficial for creating personalized products or adding unique markings to existing items. Whether it’s engraving names on plaques or designing custom logos on promotional items, laser engraving provides a high level of customization.

In addition to precision, laser engraving offers durability. The engraved marks are permanent and resistant to fading or wearing off over time. This makes laser-engraved items ideal for long-lasting personalization or branding purposes. Whether it’s a personalized gift or a company logo on a product, laser engraving ensures that the mark will remain intact for years to come. The durability of laser engraving makes it a popular choice for creating keepsakes or commemorative items.

| Benefits of Laser Engraving: |

|---|

| 1. Precision engraving on various materials |

| 2. Durable and long-lasting marks |

| 3. Versatile customization options |

| 4. Suitable for personalization and branding |

Laser engraving also offers a wide range of customization options. The laser beam can be adjusted to create different depths of engraving, allowing for various effects. From shallow surface etching to deep engraving, laser engraving can achieve the desired result based on the material and design requirements. Additionally, laser engraving can incorporate intricate details, fine lines, and even grayscale images, providing endless possibilities for customization.

Whether it’s for personal or business use, laser engraving provides a versatile and innovative method of customization. From creating unique gifts to branding products, the precision, durability, and flexibility of laser engraving make it a popular choice for individuals and businesses alike.

Benefits of Laser Engraving Business

Starting a laser engraving business comes with several benefits. Laser engraving businesses can tap into the growing trend of customization, offering personalized products to customers. The versatility of laser engraving allows for customization on a wide range of materials, from metal and glass to fabric and wood. Laser engraving businesses can cater to different industries, including fashion, arts and crafts, and manufacturing. With the right planning and strategy, a laser engraving business can capture the market’s attention and find success.

Customization:

One of the main advantages of a laser engraving business is the ability to offer customization. In today’s market, individuals and businesses are seeking unique and personalized products. Laser engraving provides the opportunity to create one-of-a-kind items by adding personalized designs, names, or messages to various materials. This level of customization sets laser-engraved products apart from mass-produced alternatives.

Versatility:

Another benefit of a laser engraving business is its versatility. Laser engraving machines can work on a wide range of materials, including metal, glass, wood, acrylic, leather, and more. This versatility allows businesses to cater to different industries and offer a diverse range of products. Whether it’s creating custom jewelry, trophies, signage, or promotional items, a laser engraving business can adapt to various customer needs and market demands.

Profitability:

A laser engraving business can be a profitable venture. With low overhead costs and the potential for high-margin products, entrepreneurs can achieve a solid return on investment. The customization aspect of laser engraving often commands premium prices, as customers are willing to pay for unique and personalized items. Additionally, as the demand for customized products continues to grow, laser engraving businesses have the opportunity to capture a niche market and establish a loyal customer base.

| Benefits of Laser Engraving Business | Description |

|---|---|

| Customization | Laser engraving allows for personalized designs and messages on various materials. |

| Versatility | Laser engraving machines can work on a wide range of materials, catering to different industries. |

| Profitability | A laser engraving business can be profitable due to low overhead costs and high-margin products. |

Licensing and Equipment for Laser Engraving Businesses

Starting a laser engraving business requires careful consideration of the necessary equipment and licensing requirements. In order to provide high-quality engraving services, entrepreneurs need to invest in specific tools and machines that are designed to perform laser engraving tasks efficiently and accurately. Additionally, obtaining the proper licenses and certifications is crucial to ensure compliance with local regulations and industry standards.

Licensing:

Licensing requirements for laser engraving businesses can vary depending on the location and specific regulations. Entrepreneurs should research and contact their local authorities to determine the necessary permits and licenses needed to operate their business legally. This may include obtaining a general business license, as well as any additional licenses related to laser operation and safety.

Equipment:

When it comes to equipment, the centerpiece of a laser engraving business is the laser engraving machine itself. These machines utilize laser technology to etch or engrave designs onto various materials such as wood, glass, metal, or acrylic. It is important to choose a machine that suits the specific needs of the business, considering factors such as the size of the work area, laser power, and compatibility with different materials.

In addition to the laser engraving machine, other essential equipment includes a computer with graphic design software to create and modify designs, protective eyewear to ensure safety during operation, and materials for testing and practicing engraving techniques. It is recommended to invest in high-quality equipment to ensure consistent and precise results.

Setting up a laser engraving business requires entrepreneurs to acquire the necessary licensing and invest in suitable equipment. By complying with legal requirements and equipping themselves with the right tools, aspiring laser engravers can establish a successful and thriving business in the growing customization industry.

Conclusion

Understanding the structure of a laser company is crucial for aspiring entrepreneurs who want to start their own laser cutting or engraving business. By grasping the basic operating principles of lasers, the significance of the laser cavity, and the unique characteristics of laser light, individuals can lay a solid foundation for their ventures.

Laser cutting and engraving businesses offer versatile customization services that cater to a diverse range of industries and customer demands. With the right equipment, careful planning, and effective marketing strategies, entrepreneurs can establish successful businesses in the field of laser engraving.

Whether it’s offering personalized products or providing custom engraving services, laser engraving businesses have the opportunity to tap into the growing trend of customization. The versatility of laser engraving allows entrepreneurs to work with various materials like metal, glass, fabric, and wood, enabling them to serve different industries such as fashion, arts and crafts, and manufacturing.

By acquiring the necessary equipment, obtaining the required licenses, and investing in training, individuals can embark on a rewarding journey in the laser engraving business. With the knowledge gained about laser company structure and the potential of laser engraving, entrepreneurs can confidently pursue their ambitions in this exciting industry.

FAQ

What is the structure of a laser company?

A laser company operates based on the principles of lasers and utilizes them in various industries such as manufacturing, microelectronics, and biomedical applications.

How do lasers work?

Laser operation is based on stimulated emission, where excited atoms emit identical photons when stimulated by a photon, leading to optical gain.

What is the laser cavity?

The laser cavity, also known as the resonator, is at the core of a laser system and consists of two mirrors, providing feedback to enhance laser output.

What are the characteristics of laser light?

Laser light is highly monochromatic, coherent, and bright, making it suitable for various applications like telecommunications and precision measurements.

What are continuous-wave lasers?

Continuous-wave lasers produce a continuous, uninterrupted beam of light at specific wavelengths determined by the laser medium.

How can I start a laser cutting business?

Starting a laser cutting business requires minimal upfront costs compared to other enterprises and offers opportunities in various industries like fashion and arts and crafts.

What is laser engraving?

Laser engraving is a method of using a laser to remove material from the surface of an object, creating permanent marks.

What are the benefits of a laser engraving business?

Laser engraving businesses can tap into the trend of customization, offer versatile services, and cater to different industries.

What equipment do I need for a laser engraving business?

Essential equipment includes a laser engraving or cutting machine, a computer, graphic design software, and training to operate the machine safely and efficiently.

What is the structure of a laser company?

Understanding the structure of a laser company is essential for those interested in starting a laser cutting or engraving business.