Contents

- 1 Introduction: Shedding Light on the Laser Phenomenon

- 2 I. The Genesis of Laser Technology: A Historical Prelude

- 3 II. Decoding the Laser: Understanding the Science Behind it

- 4 III. Applications Across the Spectrum: Where Light Meets Innovation

- 5 B. Laser in Medicine: Healing with Precision

- 6 C. Laser in Manufacturing: Shaping Materials with Precision

- 7 Conclusion: Illuminating the Future with Laser Innovation

Introduction: Shedding Light on the Laser Phenomenon

In the realm of modern technology, lasers stand as beacons of innovation, revolutionizing various fields with their remarkable capabilities. Let’s embark on a journey to unravel the mysteries of lasers, exploring their fundamental principles and the myriad applications that have shaped our technological landscape.

I. The Genesis of Laser Technology: A Historical Prelude

A. Birth of an Idea

The inception of laser technology dates back to the mid-20th century, when visionary minds such as Theodore Maiman and Arthur Schawlow conceptualized the principles underlying the amplification of light through stimulated emission. This revolutionary idea laid the groundwork for what would become one of the most transformative inventions of our time.

B. The Laser’s Maiden Voyage

In 1960, Theodore Maiman constructed the first operational laser using a synthetic ruby crystal. This groundbreaking achievement marked the birth of an era where precision and focused light would become synonymous with progress.

II. Decoding the Laser: Understanding the Science Behind it

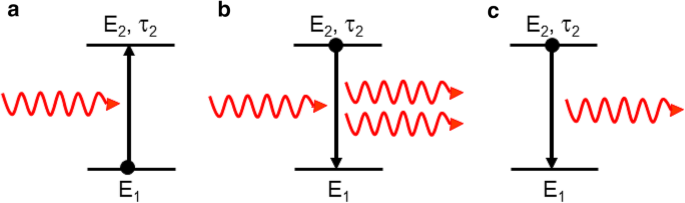

A. Stimulated Emission: The Driving Force

At the heart of laser technology lies the concept of stimulated emission. When atoms or molecules are prompted to release photons through external stimulation, a cascade effect occurs, resulting in the emission of coherent and monochromatic light. This process creates the laser’s distinctive characteristics, setting it apart from conventional light sources.

B. Coherence and Monochromaticity

Unlike conventional light sources, lasers produce light waves that are both coherent and monochromatic. Coherence ensures that the light waves are synchronized, reinforcing each other and creating a concentrated, high-intensity beam. Monochromaticity, on the other hand, means that the light consists of a single color or wavelength, contributing to the laser’s precision.

C. The Laser Medium: Diverse Materials, Common Purpose

Various materials, ranging from gases and liquids to crystals and semiconductors, serve as the laser medium. Each medium influences the characteristics of the laser beam, allowing for customization to suit specific applications. This adaptability is a key factor in the widespread adoption of laser technology across industries.

III. Applications Across the Spectrum: Where Light Meets Innovation

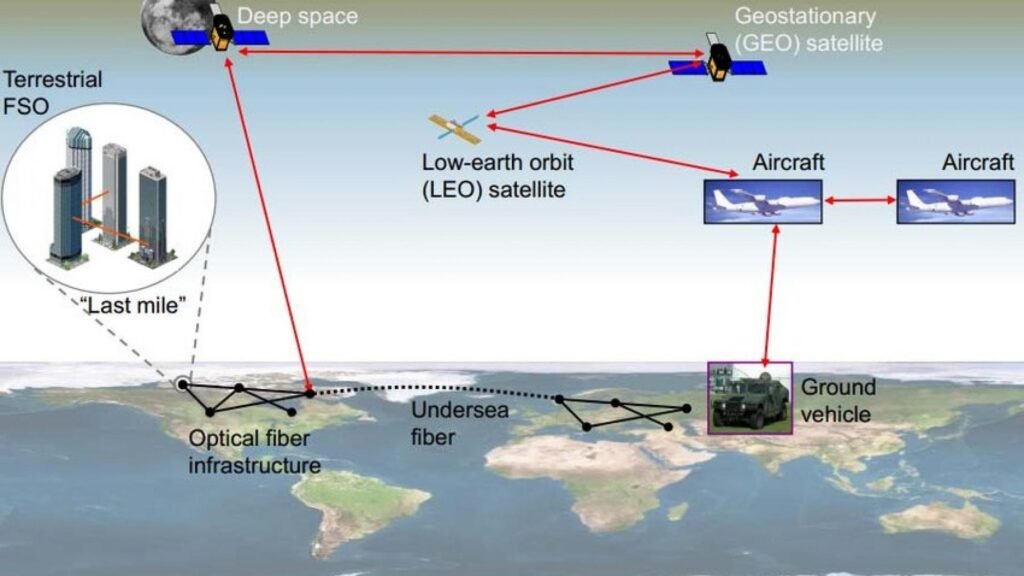

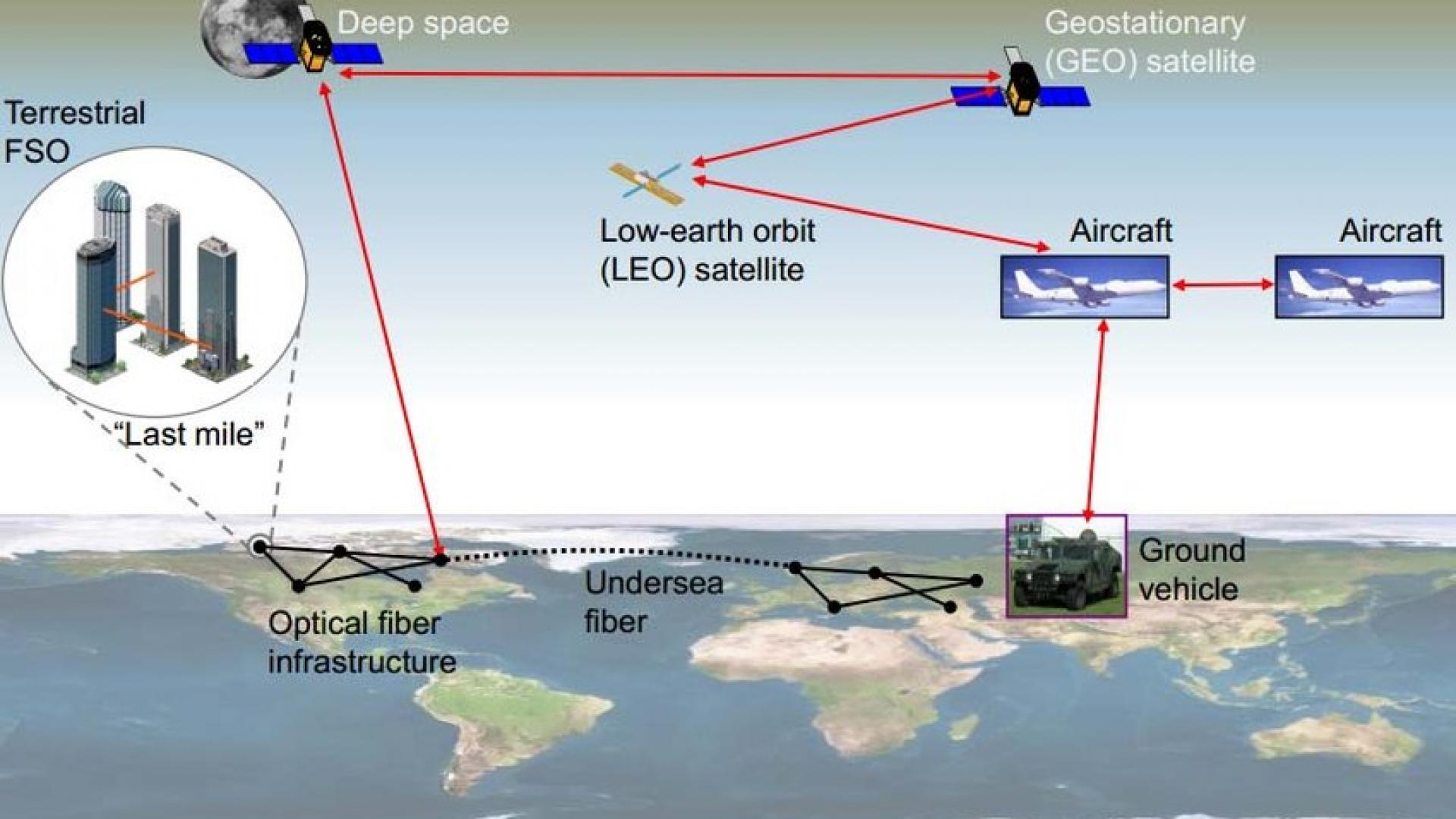

A. Laser in Communication: Bridging Distances with Light

The telecommunications industry has harnessed the power of lasers to transmit information through optical fibers. The precision and efficiency of laser beams enable high-speed data transfer, forming the backbone of our interconnected world.

Here are some ways lasers are used in communication:

-

Fiber Optic Communication:

- Transmission Medium: Lasers are used to generate light signals in fiber optic communication systems. The laser light is sent through optical fibers, which can carry large amounts of data over long distances with minimal signal loss.

- Data Transmission: The intensity of the laser light can be modulated to represent digital data. This modulation allows for the encoding of information onto the light waves, which can then be transmitted through the fiber optic cables.

-

Free-Space Optical Communication (FSO):

- Line-of-Sight Communication: Lasers are employed in free-space optical communication systems, where data is transmitted through the air without the need for physical cables. This is especially useful in situations where laying cables is impractical or expensive.

- Applications: FSO is used in point-to-point communication links, such as satellite communication, inter-building communication, and military communications.

-

Satellite Communication:

- Inter-satellite Links: Lasers are used in communication between satellites in space. This allows for high-speed data transfer between satellites in orbit.

- Ground-to-Satellite Links: Lasers can be used in ground stations to establish communication links with satellites.

-

Optical Wireless Communication:

- Intra- and Inter-vehicle Communication: Lasers are employed in optical wireless communication for vehicle-to-vehicle and vehicle-to-infrastructure communication, enabling high-speed data transfer in intelligent transportation systems.

- Indoor Communication: Lasers can be used for short-range, high-bandwidth communication within buildings or confined spaces.

-

Lidar (Light Detection and Ranging):

- Remote Sensing: Lidar systems use lasers to measure distances and create detailed, three-dimensional maps of the surroundings. This technology is used in autonomous vehicles, environmental monitoring, and other applications.

-

Optical Amplifiers:

- Signal Boosting: Lasers are used as optical amplifiers in fiber optic communication systems to boost the strength of optical signals, allowing data to be transmitted over longer distances without significant signal degradation.

B. Laser in Medicine: Healing with Precision

In the medical field, lasers have become indispensable tools for surgeries, dermatology, and diagnostics. The ability to precisely target tissues and perform non-invasive procedures has revolutionized medical practices, enhancing patient outcomes and recovery.

Here are some key applications of lasers in the field of medicine:

-

Surgery:

- Laser Surgery: Lasers are widely used in various surgical procedures. They can cut, coagulate, or vaporize tissues with high precision, minimizing damage to surrounding healthy tissue.

- Dermatology: Lasers are used for cosmetic and medical dermatological procedures, such as laser hair removal, tattoo removal, and treatment of skin conditions like acne scars and birthmarks.

-

Ophthalmology:

- Laser Eye Surgery: Procedures like LASIK (Laser-Assisted In Situ Keratomileusis) use lasers to reshape the cornea, correcting refractive errors and reducing or eliminating the need for glasses or contact lenses.

- Retinal Surgery: Lasers are used to treat retinal conditions, including diabetic retinopathy and retinal detachment.

-

Dentistry:

- Soft Tissue Procedures: Lasers are employed for various dental procedures, including gum surgery, removal of soft tissue lesions, and treatment of periodontal disease.

- Tooth Whitening: Lasers are used to enhance tooth whitening procedures.

-

Cancer Treatment:

- Photodynamic Therapy (PDT): In PDT, a photosensitizing agent is administered, and then a laser is used to activate the agent selectively in cancer cells. This leads to the destruction of cancer cells.

- Laser Ablation: Lasers can be used for the removal or destruction of tumors, either through direct ablation or by activating photosensitive agents.

-

Endoscopy:

- Endoscopic Procedures: Lasers are integrated into endoscopic devices for procedures in the gastrointestinal tract, respiratory system, and other internal organs. They can be used for cutting, coagulation, and tissue ablation.

- Laser Lithotripsy: Lasers are used to break down kidney stones and other urinary tract stones during endoscopic procedures.

-

Therapeutic Applications:

- Pain Management: Low-level laser therapy (LLLT) is sometimes used for pain management and to promote tissue healing.

- Dental Cavity Treatment: Lasers can be used to remove tooth decay and prepare teeth for restorative procedures.

-

Diagnostic Imaging:

- Laser Scanning Imaging: Lasers are used in imaging technologies like confocal microscopy and optical coherence tomography (OCT) for high-resolution imaging of tissues at the cellular or molecular level.

-

Photocoagulation:

- Treatment of Vascular Conditions: Lasers are used in photocoagulation to seal or cauterize blood vessels, addressing conditions like diabetic retinopathy and certain vascular abnormalities.

C. Laser in Manufacturing: Shaping Materials with Precision

Industries such as manufacturing and materials processing leverage lasers for cutting, welding, and engraving. The focused and intense beams allow for intricate detailing and precision, contributing to the production of high-quality goods.

Here are some key areas where lasers are employed in manufacturing:

-

Cutting and Welding:

- Laser Cutting: Lasers are used for precise and clean cutting of materials such as metals, plastics, and ceramics. Laser cutting is widely used in industries like automotive, aerospace, and electronics for shaping and profiling materials.

- Laser Welding: Lasers can be used for both traditional welding and micro-welding applications, providing high precision and minimal heat-affected zones. This is particularly useful in joining thin materials.

-

Additive Manufacturing:

- 3D Printing: Laser-based additive manufacturing processes, such as selective laser sintering (SLS) and stereolithography (SLA), are used to create three-dimensional objects layer by layer. This is used in rapid prototyping, custom part production, and even in the production of end-use components in industries like aerospace and healthcare.

-

Marking and Engraving:

- Laser Marking: Lasers are used for marking and engraving logos, serial numbers, and other information on a variety of materials, including metals, plastics, and ceramics. This is common in industries where traceability and product identification are critical.

- Deep Engraving: Lasers can create deep engravings for decorative or functional purposes, such as mold cavities for embossing on products.

-

Micro-Machining:

- Precision Machining: Lasers are used for micro-machining applications, where high precision is required for small components in electronics, medical devices, and other industries.

- Micro-Drilling: Lasers are employed for drilling extremely small holes in materials, often at a microscopic level, for applications like fuel injection nozzles and medical devices.

-

Surface Treatment:

- Laser Surface Hardening: Lasers can be used to selectively heat and harden specific areas of a material’s surface, improving wear resistance and durability.

- Laser Cleaning: Lasers are used for removing contaminants, coatings, or rust from surfaces without damaging the underlying material.

-

Quality Control and Inspection:

- Laser Inspection Systems: Lasers are utilized in quality control processes for non-destructive testing and inspection of manufactured components. Laser-based measurement systems provide accurate and rapid assessments of dimensions and tolerances.

-

Materials Processing:

- Surface Modification: Lasers can modify the surface properties of materials, such as altering the color or creating specific textures for aesthetic or functional purposes.

-

Laser Heating:

- Hardening and Tempering: Lasers are used for controlled heating processes, such as hardening and tempering of materials, to achieve specific mechanical properties.

Conclusion: Illuminating the Future with Laser Innovation

As we reflect on the journey through the intricate world of lasers, it becomes evident that these devices are more than mere sources of light. They represent a convergence of scientific ingenuity and practical applications, shaping the way we communicate, heal, and build. As technology continues to advance, the future holds the promise of even more astonishing breakthroughs, with lasers at the forefront of innovation.