Contents

Source: LightTrans

Understanding VCSEL Arrays: A Comprehensive Guide

Introduction to VCSEL Arrays

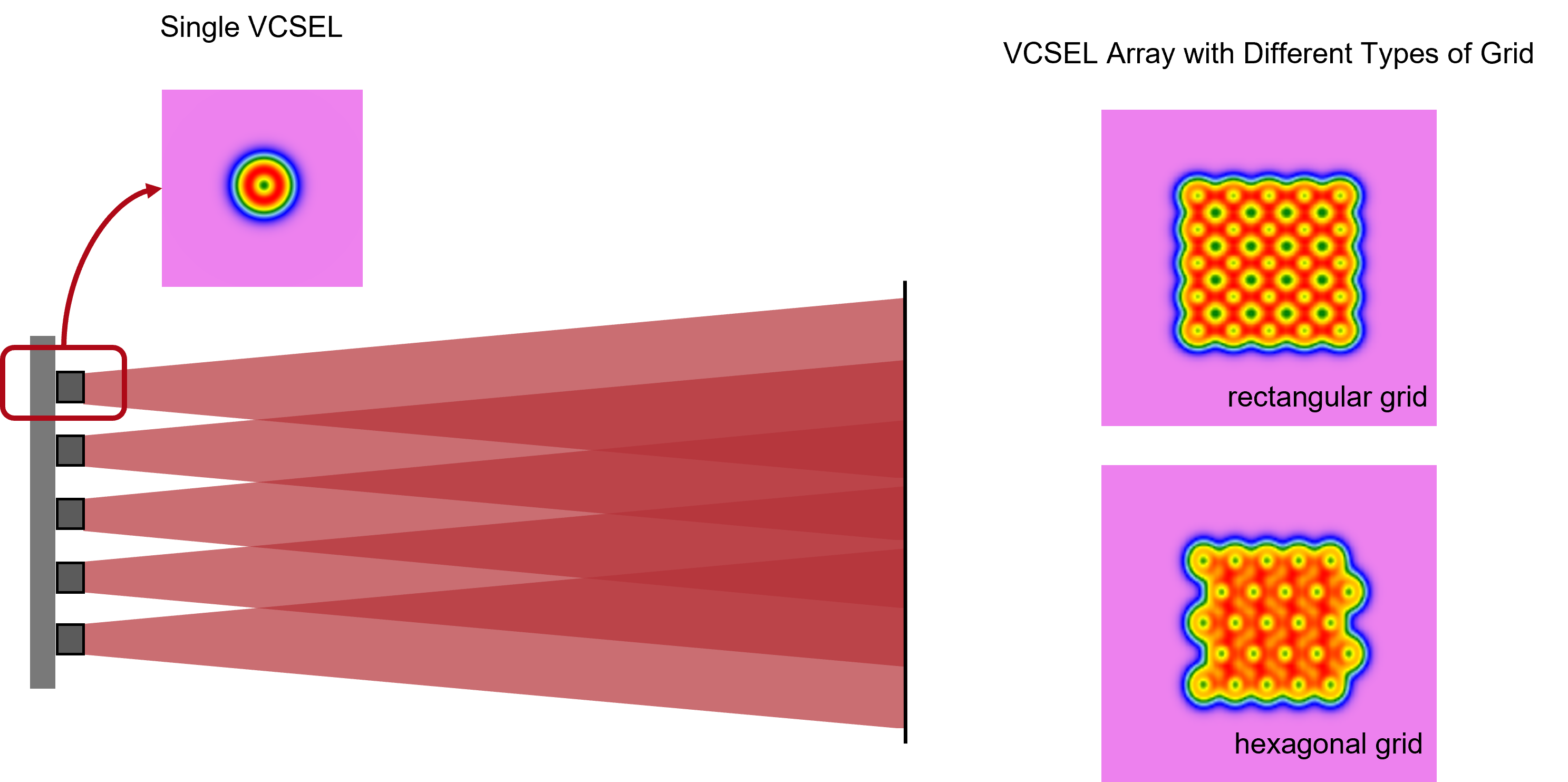

Vertical Cavity Surface-Emitting Lasers (VCSELs) are a type of laser diode that emits light perpendicular to the wafer surface. Unlike traditional edge-emitting semiconductor lasers, VCSELs can be fabricated in two-dimensional arrays on a semiconductor chip, allowing for higher combined output powers. These arrays can compete with diode bars and stacks based on edge-emitting lasers.

Production and Design of VCSEL Arrays

VCSEL technology is well-suited for wafer-level production. The fabrication process for VCSEL arrays involves techniques like metal-organic chemical vapor deposition (MOCVD) and photolithography. Arrays can have various shapes and emitter arrangements, with each emitter typically producing output powers in the milliwatt to tens of milliwatt range.

Performance and Cooling of VCSEL Arrays

The total output power of a VCSEL array is the sum of individual emitter powers. Effective cooling is crucial to manage the substantial thermal power density generated by multiple emitters. Methods such as using synthetic diamond heat spreaders and microchannel coolers help in efficient heat dissipation.

Beam Quality and Power Scaling

Increasing the number of emitters in a VCSEL array can scale up the output power, but it may reduce beam quality. Beam quality can be optimized by maximizing the power efficiency of individual emitters, minimizing emitter spacing, and employing optical feedback for coherent emission.

Applications of VCSEL Arrays

VCSEL arrays find applications in various fields, including pumping solid-state lasers, thermal material processing, illumination systems, and optical communications. Their low beam divergence and high output power make them versatile for different uses, from industrial processes to scientific research.

Future Developments and Advancements

Ongoing research aims to enhance the efficiency, beam quality, and power scalability of VCSEL arrays. Innovations in cooling technologies, fabrication processes, and beam collimation methods are driving the evolution of VCSEL technology for broader applications and improved performance.

Source: Elektronik Net

Feel free to comment your thoughts.