Contents

Source: YouTube

Fusion Splicing: Techniques and Applications

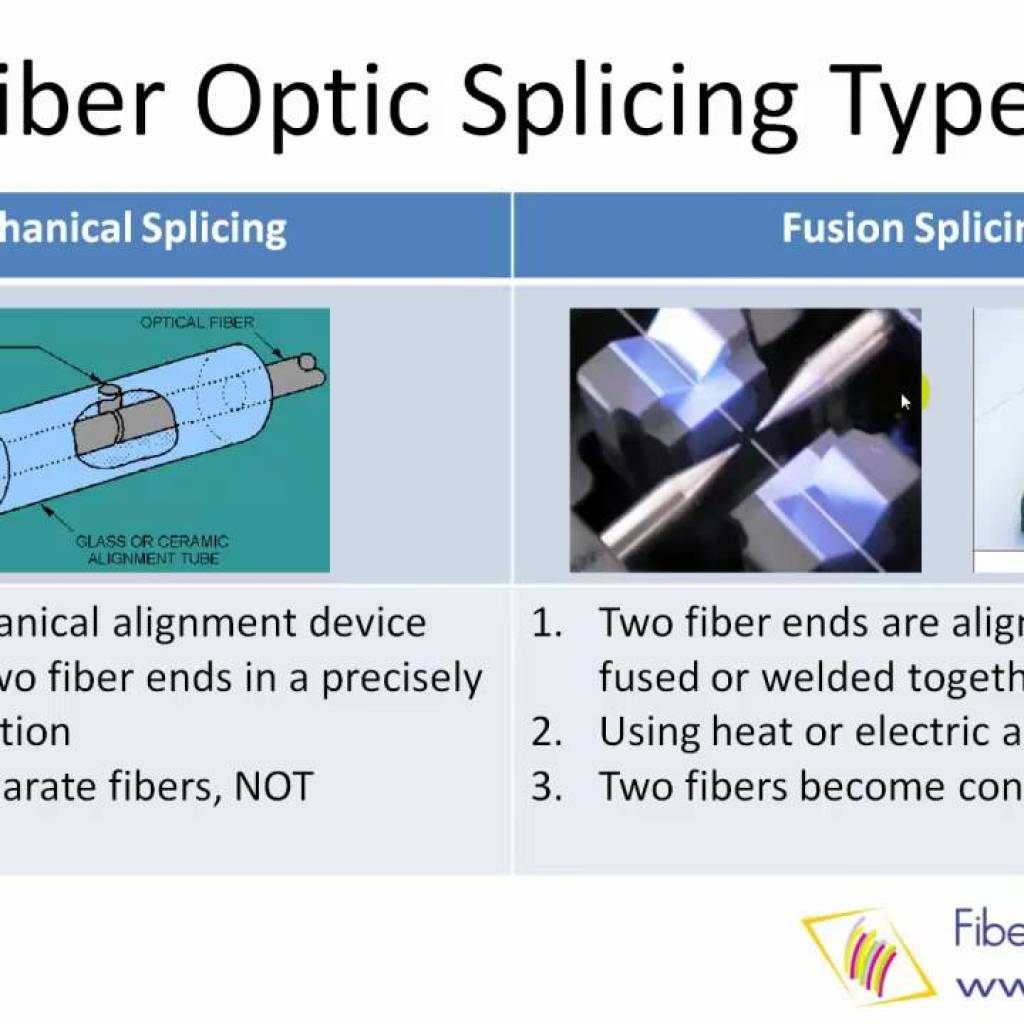

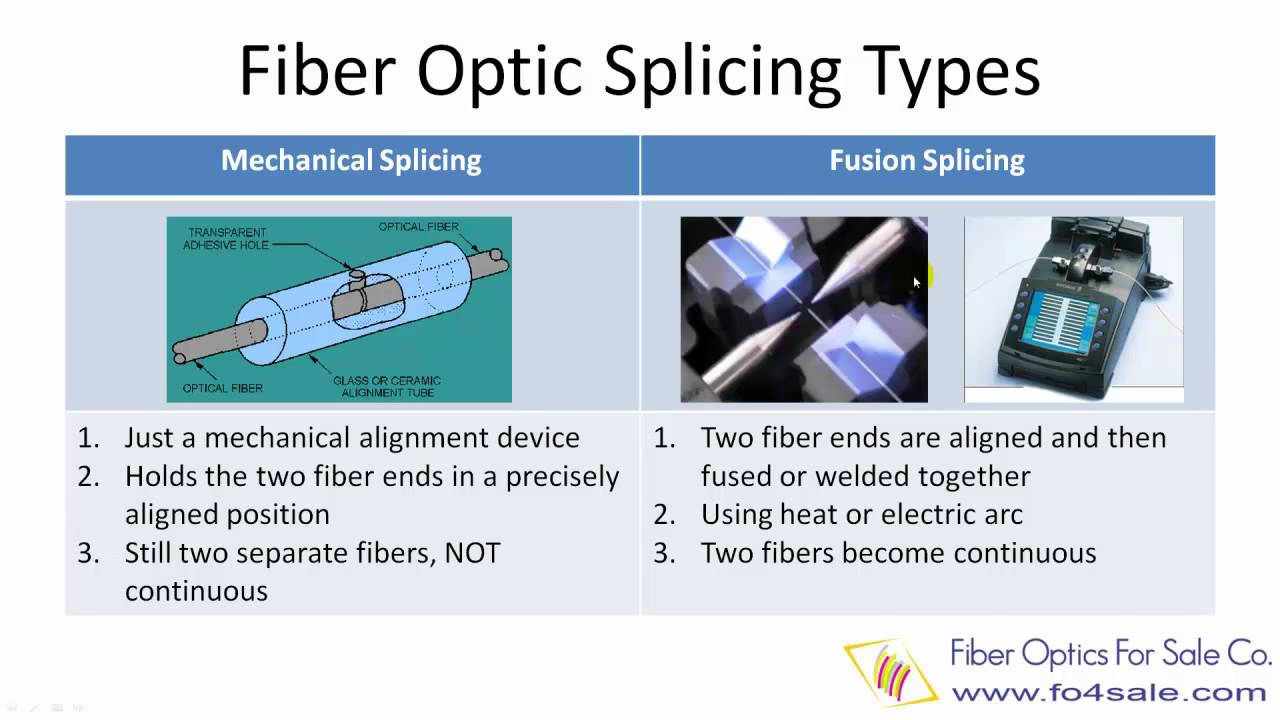

Introduction to Fusion Splicing

Fusion splicing is a prevalent method used to join two optical fibers end-to-end, ensuring a continuous and efficient light signal transmission. This process involves aligning the fiber ends and heating them until they fuse together, typically using electric arcs or other heat sources.

The Fusion Splicing Process

Preparation and Alignment

Before splicing, the fiber coatings are removed to expose the bare fiber ends. The ends are then aligned with precision, ensuring that the cores are directly opposite each other. This step is crucial for minimizing signal loss and ensuring a strong splice.

Heating and Fusing

Once aligned, the fiber ends are heated using various methods such as high-voltage electric discharge, CO2 lasers, or gas flames. The heat causes the fiber surfaces to melt slightly, allowing them to fuse when brought into contact.

Surface Tension and Alignment

Surface tension aids in achieving proper alignment, especially when the fiber cores are centered. However, misalignment can occur if the fiber ends are not perfectly perpendicular or if there are differences in core sizes.

Critical Factors for Successful Fusion Splicing

Material Compatibility

Fusion splicing is most effective with silica fibers. Other glass materials may not be suitable due to differences in thermal properties and melting points.

Optimized Splicing Parameters

For a successful splice, the splicing parameters such as electric current and arc duration must be optimized for the specific fiber type, considering factors like material and diameter.

Fiber Preparation

Proper fiber preparation includes removing coatings, making precise perpendicular cuts, and ensuring a clean, dust-free surface. Using a fiber cleaver can achieve the necessary precision, while polishing can enhance surface quality.

Applications and Benefits of Fusion Splicing

Low-Loss Connections

Fusion splicing offers minimal transition losses and negligible reflection, making it ideal for high-performance applications. The resulting joints are stable and resistant to environmental factors.

Robust and Durable Splices

While the splice itself is robust, the surrounding area may be vulnerable to damage. Applying a protective coating or sleeve post-splicing enhances mechanical strength and longevity.

Versatile Applications

Fusion splicing is widely used in telecommunications, data centers, and manufacturing of fiber-optic devices. It is particularly valuable in creating long, continuous fiber runs in outdoor installations.

Challenges and Considerations

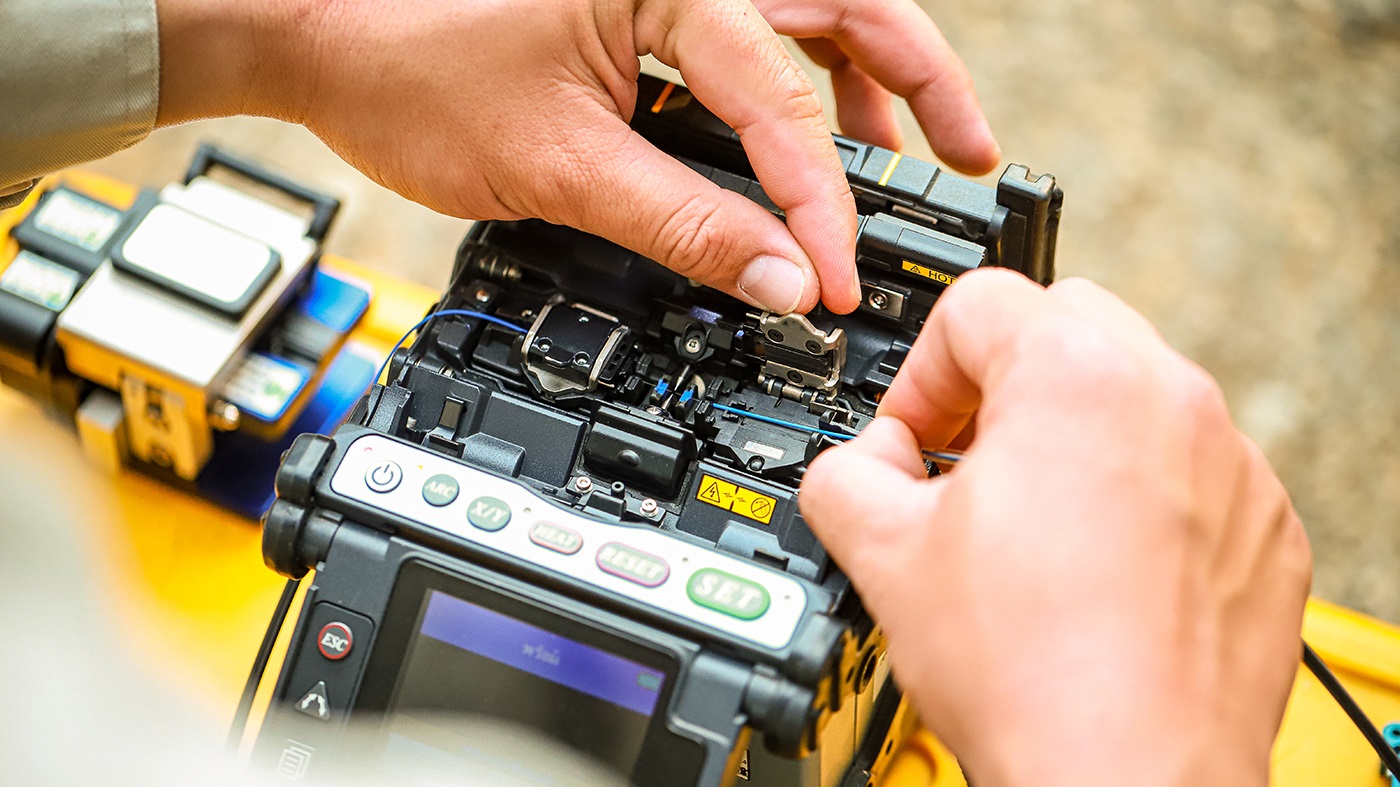

Equipment and Training

The equipment required for fusion splicing can be expensive, and proper training is essential to ensure optimal results. The process can be less convenient for fieldwork due to its complexity and power requirements.

High-Power Applications

In high-power fiber lasers and amplifiers, any light lost in splices can cause damage, emphasizing the need for high-quality splicing to prevent operational issues.

Conclusion

Fusion splicing remains a critical technique in the field of fiber optics, offering unparalleled performance in terms of signal integrity and connection stability. While there are challenges associated with its implementation, the benefits often outweigh the drawbacks, making it the preferred choice for many high-precision applications.

Source: STL Tech

Feel free to comment your thoughts.