Contents

Source: YouTube

<>

Z-scan Measurements: Understanding Kerr Nonlinearity

Introduction

The z-scan measurement technique is a valuable method for determining the strength of Kerr nonlinearity in optical materials. This nonlinearity, characterized by the nonlinear index, plays a crucial role in various optical phenomena.

How Z-scan Measurements Work

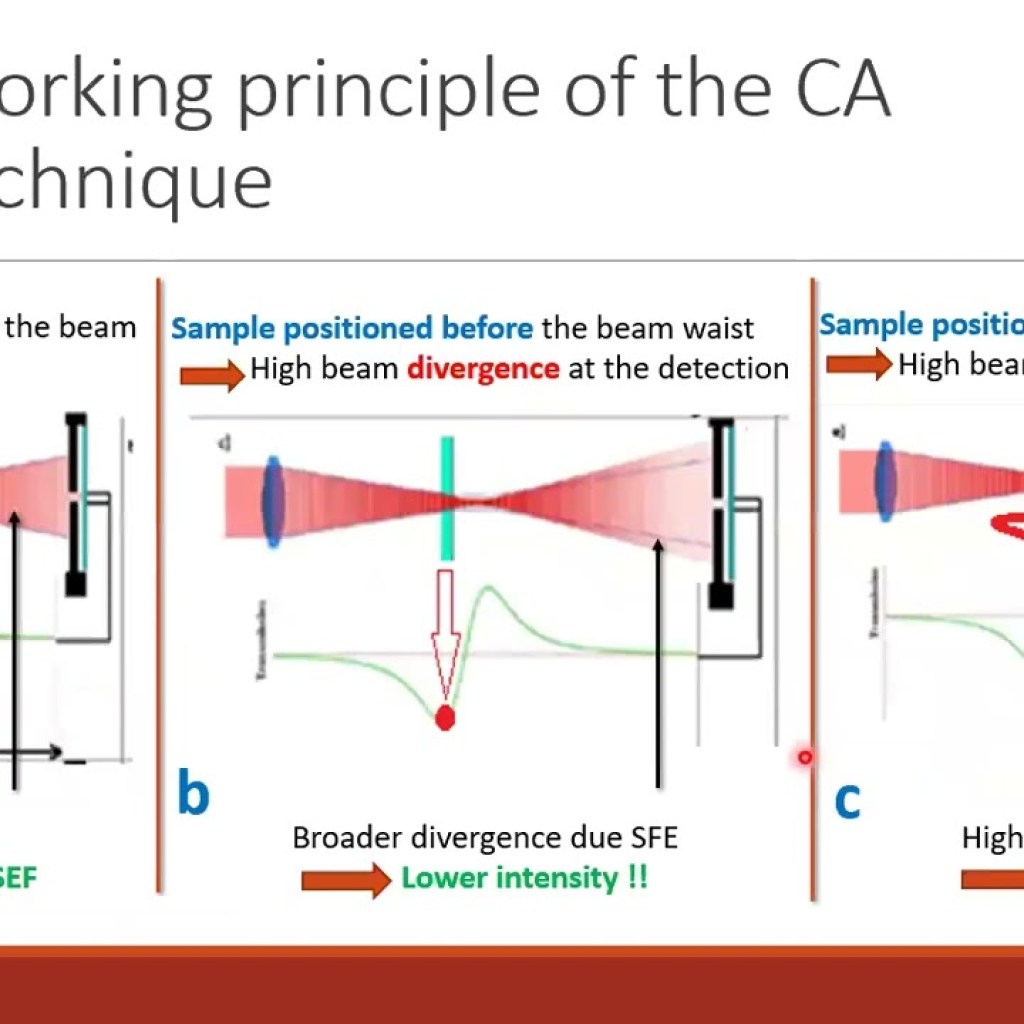

In a z-scan measurement setup, a sample material is traversed through the focus of a laser beam. The beam radius or on-axis intensity is then recorded at different positions behind the focus. The self-focusing effect comes into play, influencing the detector signal based on the sample’s position relative to the focus.

Interpreting Results

By analyzing the variations in the detector signal with respect to the sample position, researchers can quantify the magnitude of the nonlinear index. This information is essential for understanding the material’s optical properties and its behavior under intense laser irradiation.

Challenges and Considerations

It’s important to note that factors like nonlinear absorption, such as two-photon absorption, can also impact the measured signal. Researchers need to account for these effects to ensure accurate characterization of the Kerr nonlinearity.

Applications and Future Developments

Z-scan measurements have applications in fields like nonlinear optics, material science, and laser technology. Ongoing research aims to refine measurement techniques, expand the range of materials that can be studied, and enhance our understanding of nonlinear optical phenomena.

Conclusion

Overall, z-scan measurements provide valuable insights into the Kerr nonlinearity of optical materials. By leveraging this technique, researchers can delve deeper into the fascinating world of nonlinear optics and pave the way for innovative applications in photonics.

Source: ResearchGate

Feel free to comment your thoughts.